How to Cite | Publication History | PlumX Article Matrix

Sharareh Rashidi1, Ahmad Halaji Sani2 and Shahab Razavi3

1Chemical Engineering Biotechnology, Islamic Azad University, North Tehran Branch, Tehran, Iran.

2Faculty Member of Engineering Department, Tehran University, Tehran, Iran.

3Chemical Engineering Biotechnology, Islamic Azad University, North Tehran Branch, Tehran, Iran.

DOI : http://dx.doi.org/10.13005/bbra/2582

ABSTRACT: Every industrial activities resultes in the pollution of environment. This pollution could be in the shape of voice, weather, and water or earth pollution. The amount of pollution in industries is different and it depends on the type of industry. So to purify and remove pollution, should know accuracy the amount and the type of pollutants. The sewage in the automotive industry includes 2 parts: Paint sludge produced in the automotive industry has the highest pollutant capability because of weighty elements. So, the removal of it in the wrong way will cause damage to the environment. In this research, a number of experiments were carried out to identify the main pollutants in the paint sludge. In this research, the method of research and data gathering was the use of a slurry bioreactor with the capability of the regulation of the amount of aeration and mixing speed to remove organic compounds of paint sludge. The experiment was designed according to the Taguchi method, which 9 experiments were designed to achieve the desired result. The results of the two experiments showed a significant reduction in the initial COD of 76 and 80% biologically pure and it became clear that aerobic bacteria purify the paint sludge more. Also, after analyzing all the results of Mini-Soft software, optimal purification conditions for effective environmental parameters were pH = 7, stirring speed = 14 rpm, dissolved oxygen concentration = 5.5 ppm. Finally, after the activation of the reactors to filter 1 kg of paint sludge for 30 days and at ambient temperature, the result of the two experiments showed a significant reduction in the initial COD of the biological treatment of 76 and 80%, and it was found that the aerobic bacteria do more the color sludge purification. Also, after analyzing all the results with mini-tab software, the optimum refining condition for effective environmental parameters was pH = 7, active sludge = 0.5 kg, stirring speed = 14 rpm, dissolved oxygen concentration = 5.5 ppm.

KEYWORDS: Color Sludge; Taguchi; Mini-Tab Software

Download this article as:| Copy the following to cite this article: Rashidi S, Sani A. H, Razavi S. The Effect of Environmental Conditions on the Removal of Organic Compounds from Color Sludge via Bioslurry Method. Biosci Biotech Res Asia 2017;14(4). |

| Copy the following to cite this URL: Rashidi S, Sani A. H, Razavi S. The Effect of Environmental Conditions on the Removal of Organic Compounds from Color Sludge via Bioslurry Method. Biosci Biotech Res Asia 2017;14(4). Available from: https://www.biotech-asia.org/?p=28747 |

Introduction

Environmental pollution threats the international community from different aspects. The maintaining the environment from pollutants is the problem that modern human has understood its importance and has experienced the effect of not attention to it. In the resent years, the development of industry and technology has caused the growth of pollutant production. The automotive industry also has a major role in the environmental pollution. Industries such as the automotive industry are among the big industries that have different units. The paint part of these industries produce The highest amount of hazardous waste because of the use of hazardous materials such as heavy metal paints, various solvents such as thinner, alkaline and acid compound, etc. So, it is important to know the process of formation of color sludge due to the detection of its production process. (Khezri et al., 2009)

These colors are usually resistant against destruction by wastewaters purification units and distribute within the environment as unrefined. So it causes surface contamination and change the groundwater in the world to their place (Keharia and Madamwar, 2003).

The production rate of color sludge in automotive industries has been a lot and every automotive factory almost produces 5-10 tons sludge every day. So, thinking about the retrieval of the value materials and neutralization of remains part is very important (Khezri and Abdollah, 2009).

The aim of this study is to find and state a nature, environmental and economic ways to eliminate the pollutants in wastewater color sludge in the automotive industry with an aerobic Bioslurry method from microorganisms. According to necessity of this field within and outside of country, purification this kind of wastewaters will be stated to refine the output color sludge from automotive factories and to stop the increasing pollutant nature environmental sources and to create economical system. In this investigation the effective environmental factors on the efficiency of elimination contaminate from the color sludge of automotive industries will be evaluated such as the amount of aerobic microbial PH injection and stirring conditions by biological system of the active sludge from the aerobic kind by use of bioreactor. To experiment, the color sludge of automotive industries is used as contaminant sources and active sludge of a refinery in the factories is used to create microbial phase.

In this study, three bioreactors with the ability to adjust the amount of aeration and stirring speed were built. By use of them, the amount of purification of color sludge of activated sludge bacteria in the automotive industries was evaluated as one of the nature environmental problems. The amount of injection of activated sludge and stirring speed, PH and the amount of aerobic are the effective environmental parameters in experiments. The experiment was designed by use of Taguchi method in three levels and four columns that showed none experiments with different conditions to get optimal position. COD test was used to get a biological purification amount on the first, 20th and 30th days. At the beginning of all experiments to supply nutrients, glucose powder, urea fertilizer and super phosphate fertilizer were added to the reactors with ratios of C / N = 5 and N / P = 10.

The Variables Related to the Concept

Color Sludge

Color sludge includes color components such as raw polymer resins, pigment surfactant and other materials in the color formulation. Also, it has water and different organic solvents. The presence of raw polymer resin, which creates color on the parts with heat or other methods, produces hard and sticky color sludge (Ruffino & Zanetti, 2011).

Color sludge is a chemical material, which is produced in the color parts in automotive industries. Color sludge has a high level of contamination because of having dangerous chemical materials such as the colors included heavy metals, different solvents such as thinner, alkaline and acid compounds etc. So, the removal of it creates a lot of problems to nurture the environment. Therefore, the disposal of these chemical compounds requires high accuracy and good equipment. If these compounds are not refined, they damage to the ecosystem and human beings and damage to the environment which will be irreparable. By refining these compounds, in addition to reduce the amount of pollutants, valuable materials can be obtained from these compounds.

Among the materials that can be obtained from color sludge is alumina which widely used in metallurgy industry. Other applications of this material are:

Production of color from color sludge by Colliers International Company and German company Chrysler;

Production of cements from color sludge and conversion Color sludge to expansion joint by Mitsubishi Company;

Production of adsorbent and waterproof composite ceramics by Ford Company;

Using color sludge in production of blast reducer in steel production furnaces by the Japanese Gunma company;

Production of railings for pavement, highway and parking blocks, coating materials Roof, low-strength concrete and building pavement by Toyota company,

Using color sludge as filler in products such as: sealant, plastics, colors and ceiling coverings by Nascote Industries and using it for production of lightweight grain materials by the Canadian Agglurykari Company. (Khezri & Abdollah, 2014)

There are elements with different percentages such as Cr, Cl, Fe, Ti, K, Na, Mg, Ca and … in a color sludge sample. Studies have shown that the color sludge has high moisture content about 70%, and has an unpleasant smell because of the presence of sulfur compounds in it. Sludge drying reduces its unpleasant smell. As a result of heating this sludge, harmful compounds such as sulfides and organic compounds disappear and only a mixture of metal oxides will remain. (Khazari and Abdollah, 2014)

Bioreactor

Bioreactor is a device or system that provides mechanical or biological activated environment to produce cells and living textures. The design of bioreactors is a very complex engineering process. The forces applied to bioreactors can be under static or dynamic conditions. These forces include shear, electrical, magnetic, mechanical-dynamical, mechanical -static and hydrostatic forces.

The components of the bioreactors include: 1- planting Container 2-piston, 3-timer, and 4-compressor.

|

Figure 1: Bioreactor building

|

Taguchi Method

A basic activity of the quality engineering is to design and experiment to get information to analyze. Taguchi defined an experimental as creation a change in a process to study its effects, but he knew multi factors method at every time as the effective method to experiments. According to the ideas of Hicks, Taguchi, Fadke, Montgomery, different steps of the experiment are:

Planning the experiment

Design experiments

Experimenting and gathering data

Analyzing data and determining the optimal point (optimal combination of the factors)

Implementations and feedback to control and adapt predictions in practice(Molarezaee, 2014)

A lot of expenses are spent on optimizing production processes by experiments in research and development centers of factories. Using different methods in the design of these experiments is very important because these experiments are time consuming and expensive due to a lot of interference parameters. Taguchi experiments are the methods used in the design of experiments. In late 1940, Taguchi introduced new statistical concepts and later it was proved that these concepts are valuable tools in the field of control and quality improvement. Taguchi method has high quality in comparison to conventional and commonly used engineering methods. Taguchi had subdivided this method to three steps, including designing system, designing a parameter and designing tolerance to control quality. (Moradkhani and Taghavi, 2007)

Activated Sludge

The activated sludge process was developed several years after the bio filter and was used in the sewage industry. This method is based on the biological floating growth (immersed microbial masses in sewage) which is active in the decomposition of organic solvents in the sewage. The wastewater (sewage), which contains organic materials and nutrients for biological growth, enters the aeration container. In this container, the air is added to the sewage through a mechanical aeration system (surface) or by pressure compressors to create soluble oxygen in the environment. The microorganisms in the aeration container grow by using organic matter in sewage and the soluble oxygen and thus the soluble organic matter becomes microbial mass (insoluble). After a several hours stop in the aeration pool, the sewage along with the microbial floating masses to the sedimentation container is transferred and in this reservoir the masses and clots formed from the microorganisms are deposited and returned to the aeration reservoir to maintain the concentration of microbes in the aeration reservoir by the pump. This is said the return flow of sludge (Vakhshor et al., 2013)

The concept of activated sludge has been created due to the return of biological suspension containing microorganisms and their active participation in the process of removing solvent organic materials in the aeration part. The activated sludge system can be known as a reactor is somewhat closed due to the fact that, although Fluid and biological mass (Biomass) participating in the reaction in the same isolation area, they are separated from each other (secondary sediment part), but a significant portion of biological mass is returned to the reactor (returned sludge). In the activated sludge system, required oxygen for Perform biological activities with the help of mechanical equipment (aerations) from depth or from the bottom is transported to the fluid. Activated sludge processes are defined based on the aeration’s duration time indexes, BOD loading per unit volume, feed ratio to the microorganism and sludge age. The important biological principle in the activated sludge method is to create the conditions that bacteria use the soluble nutrients in the sewage in the cellular metabolism process and converted to cellular material with the best possible efficiency, and eventually this cell mass is removed as a sludge from the purification system. The general purpose of this paper is to general investigation of sludge method in the sewage purification. The effective parameters in this method and the mathematical relations governing them are how loading facilities, activated sludge capabilities, purification processes of sewage using the activated sludge, process control basics, process design considerations, major activated sludge control approaches, etc. (Masoumi, 2012).

Organic compounds

Compounds are organic compounds which the main building elements are carbon and hydrogen. In the building of organic compounds, in addition to carbon and hydrogen, there are elements such as oxygen, nitrogen, sulfur, phosphorus, etc. The various types of carbon compounds present in the remaining plant or animal that is in different stages of decomposition, organic matter is referred.

Carbon Sources

Organic compounds.

Mineral compounds such as carbon dioxide and bicarbonates.

The Effective Environmental Factors

In every bioreactor, the elimination of organic compounds in the range pH 6-9 is tolerable and the proper function occurs at near neutral pH. Another important factor is the concentration of dissolved oxygen in the reactor that proper amount is 20 mg/l and in the concentration more than 50 mg/l, the dissolved oxygen concentration has less effect on the decomposition rate. another environmental factor is proper temperature, which is various depending on type of microorganisms. (Sedlak, 1991)

Automotive Industry Wastewater

The sewage is created in the automotive industry are industrial sewage and human sewage.

These two kinds of automotive industrial wastewater are produced in these saloons:

Color saloon

Body and assembly saloon

Chemical warehouse

Central engine room and compressor

Chassis building saloon

In the color and chassis building saloon, both industrial sewage and human sewage are produced. Whereas in the other three parts, body and assembly saloon, chemical warehouse and central engine room and compressor, there is only human sewage and industrial sewage is not produced or the quality of producing sewage is such a way it does not enter the refinery of sewage. Such as the sewage from the washing of water filters without soluble, due to its excellent quality, there is no need to drain to the refinery. (Khezri et al., 2009)

|

Figure 2: Production of automotive industry wastewater

|

Sewage Treatment System

The sewage treatment system includes functional units and process units. The functional units use physical methods to eliminate pollutants. The process units use biochemical or chemical methods to eliminate contaminates. This system is used to reduce contaminations of sewage to the limited amount. Sewage treatment systems are:

Preliminary treatment

Secondary treatment

Advanced treatment

The preliminary treatment is also called physical treatment the aim of this kind of treatment is to eliminate solid materials in sewage also some BOD is deleted in this step. The preliminary treatment which is more practical in the civic sewage includes screening, grit chamber, fat chamber and initial deposition. The secondary treatment includes transform biochemistry and colloid dissolved organic material to biological masses which are eliminated in the depositing unit. Microorganisms and organic material are related by suspending the mass of the bacteria in the sewage or passing through the sewage from the layer of sticking bacteria to the solid surface.

Biologic purification is also used to remove biodegradable substances that are soluble or colloidal .These materials during the biological decomposition turn into gases and cellular tissue. Gases are removed from the sewage system, and biological cells are separated from the sewage by secondary sedimentation. Also, in secondary purification, the pathogenic agents, refined by using disinfection units from treated wastewater. (Fallahpour, 2008)

Literature Review

Seyed Mostafa Khezri et al. In 2008 they have done research in the field of pollutants from color operations in the automotive industry. the results of this study show the sludge from the paint produced in the automotive industry has a high potential for contamination due to the presence of heavy metals. Accordingly, the incorrect disposal of those problems causes environmental problems.

In this study, several experiments were carried out to identify the main pollutants of dye sludge and provide a cost-effective solution for its recovery, including X-ray fluorescence spectroscopy (XRF) X-ray diffraction (XRD) 4 and Differential Thermal Analysis (DTA) 5 was used to determine the type and concentration of the elements and compounds present in this sludge. The results showed that this sludge contains heavy metal elements such as copper metals with a concentration of 1/5 gr / lit zinc at a concentration of 13.9 gr / lit aluminum concentration of 76.5 gr / lit magnesium with concentration of 23/004 gr / lit titanium with a concentration of 32/69 gr / lit vanadium with a concentration of 0.9 gr / lit and …. Compared to the environmental standards of these metal elements, it was found that many of them are outside the standard range and significant elemental pollutants. Therefore, the need to present practical solutions for its recovery is quite evident. Therefore, further studies are needed in order to eliminate these contaminants.

Maryam Farahani has also done research in this field. In this study, the automotive industry is one of the largest industries in the world and it is also very important in our country. The automotive industry, in terms of the World Bank’s classification, can be part of projects that have specific environmental impacts and require the preparation of an assessment report.

The automotive wastewater is mainly due to washing and coloring operations of the vehicle and chassis production stages which it contains oils and fats, seeds, phosphates, aromatic compounds, some heavy metals such as chromium, lead, mercury and other pollutants. In this study, the effluent of this industry has been investigated for the environmental points of the pollutant and predicted the negative and positive effects of these industries in the two phases of construction and operation. The effects of pollutants in the scaled and non-hazardous wastewater have been done through the rating of the effects of reducing options. In the end, in order to reduce the effects of corrective malfunctions, it is suggested that, while reducing the amount of contamination in the wastewater to meet the relevant standards, time, budget and technology factors are not overlooked.

Mattison et al. also conducted research on colored sludge recycling. The researchers used color sludge for use in building materials such as cement, asphalt, concrete, mortar and plaster. In this material, water and colored sludge have been used for hydrating materials.

Saleh Ouqlu and Kamel Ouqlu have done research on automotive paint sprayers. According to this research, the automotive industry creates a variety of trashes and waste products. Color sludges are one of these. Color dyes produced in the environment are very dangerous. A large amount of this material is produced annually. Because of the high carbon content, it cannot be buried in accordance with the EU rules. Therefore, this material must be recycled, and materials with a latent formulation should be produced. In this study, the structure of colored sludge’s and materials from the recycling of these materials has been investigated.

Methodology

Automotive wastewater is a result of washing and paints on the car and chassis production stages that contain oils and fats, dyes, creams, phosphates and other pollutants, which has a devastating effect on the environment.

In this study, the method of biological treatment of active sludge from a wide range of aeration for the removal of heavy metals and contaminants from industrial effluents and sanitary sewage has been evaluated for optimization of automobile wastewater treatment method in pilot scale.

To conduct pilot tests has been used the natural wastewater from the Bahman Automobile Plant. Factors affecting the efficiency of removal of heavy metals and contaminants such as biological concentration (MLVSS), COD, BOD, in the biological system of active auxiliary sludge have been evaluated and tested for the various industrial-human wastewater mixing ratios. The performance of the above-mentioned system in the best condition eliminates about 90 percent of the pollution load and 65 percent of the heavy metals in the industrial wastewater.

Removal of Organic Compound Methods

In general, the removal of organic compounds in aqueous solutions requires the application of one or more of the purification methods. Physical chemistry and biological methods are an example of the filtration process. Application of one or more methods depends on the concentration of pollutants in the wastewater. Selection of the most appropriate method should be in accordance with the characteristics of the organic matter concentration. Basically, choosing one or more methods depends on the cost of the process and other factors such as concentration and volume of wastewater. (Clare et al., 2002)

Removal of Organic Compounds

Physical methods

Chemical methods

Biological methods

Biodegradation of organic compounds

Biological treatment systems are living systems that rely on microbial populations. Mixtures of microorganisms decompose organic matter and separate the solution. In general, the main purpose of biological treatment processes is to convert or remove the organic matter to other products, so that the products are harmless or easily separable.

The most important point is all biological processes that played a vital role by microorganisms in the air, and they are in fact the refining machine.

Generally, in the purification systems, there are a variety of microorganisms, although among them the main role is played by bacteria. One of the most important and main products that produced in the biologic microbial growth process is the addition of additional sulfides. It is important to note that if these cells, which are produced during the removal of organic matter, are not separated from the solution, treatment has not been performed. Because the cells, which themselves are in fact of organic origin, are measured during the output as BOD or COD.

The basis of all the processes used in biological treatment is the need for microorganisms of air. For example, in the active sludge system, colloidal organic matter and solution are removed by microorganisms because these materials supply the needs of cell growth and life. (Assad Dokht, 1395).

In this study, the sludge produced was used in the paint room. Samples were taken from the sludge of the hall during two stages of holding the sludge reservoir in the outside of the hall. The following methods were used to study the type and composition of sludge in color.

The second step of the pH of the mixture was measured by the pH machine. Then the mixture was added to the desired amount by adding the caustic soda.

In the next step, the amount of activated sludge required in the first round tests of 500 grams was weighed and transferred to the desired container, and then a sample of one of the mixtures was taken for testing. Subsequently, all of the mixtures was transferred to the reactor for testing, and the reactor mixer and compressor engine were switched on.

The experiments were performed on the Taguchi method in three periods of 30 days and a total of 90 days. The experiment was repeated with different conditions, so that the results obtained with the Mini-Tab software were thoroughly investigated.

Table 1: the materials used in this test

| material | Chemical formula | permeable | |

| 1 | Urea fertilizer | 46% | |

| 2 | Triple super phosphate fertilizer | 46% | |

| 3 | Glucose powder | Monohydrate | |

| 4 | Caustic soda | Na OH | 98%Sodium hydroxide |

| 5 | distilled water | Deionize without dissolved material | |

| 6 | Color sludge | —– | Painting waste in automotive industry |

| 7 | Activated sludge | —– | Industrial wastewater treatment plant Mapna |

Table 2: Experiments based on Taguchi method

| period of experiments | Experiment number | The amount of activated sludge | pH | Stirring speed | The amount of aeration | The time of experiment |

| First

period |

1 | 0.5 kg | 6 | 14 rpm | 0 ppm | 30 days |

| 2 | 0.5 kg | 7 | 23 rpm | 4-5 ppm | ||

| 3 | 0.5 kg | 8 | 35 rpm | 6-7 ppm | ||

| Second

period |

4 | 1 kg | 6 | 23 rpm | 6-7 ppm | 30 days |

| 5 | 1 kg | 7 | 35 rpm | 0 ppm | ||

| 6 | 1 kg | 8 | 14 rpm | 4-5 ppm | ||

| Third

period |

7 | 2 kg | 6 | 35 rpm | 4-5 ppm | 30 days |

| 8 | 2 kg | 7 | 14 rpm | 6-7 ppm | ||

| 9 | 2 kg | 8 | 23 rpm | 0 ppm |

Sampling and Measurement

In each test period, three times in the first, 20th and 30th days of each reactor were sampled by a large syringe and the specimens were stored in glasses in a special bag and stored in a refrigerator at a temperature of 0°.

Table 3: the amount of COD obtained from experiments

| period of experiments | Experiment number | The amount of activated sludge | pH | Stirring speed | The amount of aeration | The time of experiment |

| First

period |

1 | 0.5 kg | 6 | 14 rpm | 0 ppm | 30 days |

| 2 | 0.5 kg | 7 | 23 rpm | 4-5 ppm | ||

| 3 | 0.5 kg | 8 | 35 rpm | 6-7 ppm | ||

| Second

period |

4 | 1 kg | 6 | 23 rpm | 6-7 ppm | 30 days |

| 5 | 1 kg | 7 | 35 rpm | 0 ppm | ||

| 6 | 1 kg | 8 | 14 rpm | 4-5 ppm | ||

| Third

period |

7 | 2 kg | 6 | 35 rpm | 4-5 ppm | 30 days |

| 8 | 2 kg | 7 | 14 rpm | 6-7 ppm | ||

| 9 | 2 kg | 8 | 23 rpm | 0 ppm |

Table 2 shows the COD obtained in the experiments. The results showed that in experiments 2 and 8, there was a significant reduction in the code of samples as compared to the first day of the experiments, indicating a high purity of color sludge of approximately 76.3% for experiment number 2 and also 80.2% is for testing the number 8. On the other hand, in the experiments of Scheme 1, 5 and 9, the COD of the samples has a very small change compared to the day of the start of the experiments. Even in some cases, it has increased from the first day, which indicates a slight reduction of the sludge by almost zero percent. In experiments No. 4 and 7, the purification rate was 23.4% and 29%, respectively, which was 45.6% and 47.9% lower than COD, compared with tests No. 3 and No. 6, and is not a good result. In total, with an eye on the results obtained, it was determined that by this method, sludge can be treated more than 75% in 30 days. This result is very positive in terms of biological treatment. Effect of pH on biological removal:

After pH measurement, each test was performed in 4 stages and within 30 days. The pH of all tests on day 10 decreased from 0.1 to 0.5 for the first day. This decrease is likely due to the acidity of colored sludge.

Table 4: The rate of pH changes in thirty days

| period of experiments | Experiment number | pH at the first day | pH at the 10th day | pH at the 20th day | pH at the 30th day |

| First period | 1 | 6 | 5.4 | 5.5 | 5.3 |

| 2 | 7 | 6.3 | 6.8 | 7.1 | |

| 3 | 8 | 7.3 | 7.3 | 4.5 | |

| Second period | 4 | 6 | 5.9 | 6.4 | 6.3 |

| 5 | 7 | 6.6 | 7 | 6.9 | |

| 6 | 8 | 7.5 | 7.4 | 7.5 | |

| Third period | 7 | 6 | 5.7 | 6.1 | 6.5 |

| 8 | 7 | 6.4 | 6.5 | 6.9 | |

| 9 | 8 | 7.6 | 7.6 | 7.7 |

By comparing the tests in Table 3, it is not enough to receive a 20-day period for each test, and it takes 30 days to reach the desired result.

The lack of purification due to the inactivation of bacteria in the environment does not cause much change in pH compared to the first day. In the alkaline environment, there was a higher percentage of COD removal than the acidic environment. That is, at pH = 8, the pH value of 6 is good and purification is done correctly. The pH has increased since the tenth day and this increase has reached neutral pH levels by the 30th day. The pH of the medium at the last day and when the filtration is well done, go to pH = 7 and neutralizes. But when it’s not good, it does not have much to do with the first day. In general, the effects of pH on the percentage of sludge filtration have been obtained using the Taguchi method and the mini pill software.

|

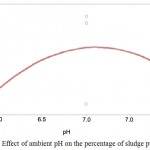

Figure 3: Effect of ambient pH on the percentage of sludge purification

|

Graph 1 shows that the pH of the environment alone has a significant effect on the colorless sludge treatment, and in general, the removal of colored sludge in the neutral environment is much more. Investigating the effect of kneading speed on biological elimination by using the data in Table 1 and putting them in the Mini-Script software, the graph of the graph 2 is obtained. This graph shows the effect of stirring speed changes on color sludge treatment.

|

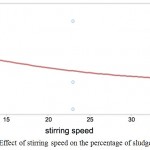

Figure 4: Effect of stirring speed on the percentage of sludge purification

|

By analyzing Graph 2, we find that the speed of stirring is higher.The amount of sludge treatment is reduced. But in general, due to the slope, the velocity changes have less effect on the other parameters than in the sludge treatment. With this in mind, the speed of 14 rounds per minute is more suitable for mixing in the reactor. It seems that increasing stirring speed reduces the activity of microorganisms and, as a result, reduces sludge treatment.

Investigating the Effect of Primary Microorganism on Biological Elimination

After observing Graph 3, it was determined that with increasing the amount of active sludge, the sludge treatment decreased. However, if this amount is increased twice as much as the amount of primary sludge, gradually sludge treatment is increased. This can be due to the production of COD by microorganisms at the beginning, which has increased COD after merging with colored sludge. But after the prevailing 77 levels of microorganisms on the sludge, the higher the amount of active sludge in the higher system, the greater the purity of the system.

|

Figure 5: Effect of increasing active sludge on the percentage of sludge purification

|

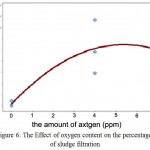

Investigating the Effect of Aeration on Biological Removal

Using the mini safe software and obtaining the graph 4, we find that the aeration has a high effect on the biological treatment of colored sludge, and the anaerobic particle size of the treatment is close to zero. This indicates the activity of aerobic microorganisms on the purification of colored sludge. It was also found that increasing the amount of aeration in the sludge treatment system significantly increased, and in the dissolved oxygen at 5.5 ppm, the sludge treatment reached its highest level. Afterwards, the higher the amount of aeration, the slope of the negative graph decreases, and the percentage of purification decreases. It can be concluded that by increasing the amount of aeration, the reactor environment is poisonous for the activity of microorganisms, and Oxygen eliminates the excess of microorganisms for treatment.

|

Figure 6: The Effect of oxygen content on the percentage of sludge filtration

|

By measuring the changes in TDS, each test was obtained in 4 steps and within 30 days of Table 5.

Table 5: TDS changes in thirty days

| Period of experiments | Experiment number | The amount of activated sludge | pH | Stirring speed | The amount of aeration | TDS at the first day | TDS at 10th | TDS at 20th | TDS at 30th |

| First period | 1 | 0.5 kg | 6 | 14 rpm | 0 ppm | 4160 | 4103 | 4229 | 4238 |

| 2 | 0.5 kg | 7 | 23 rpm | 4-5 ppm | 4208 | 3652 | 1636 | 967 | |

| 3 | 0.5 kg | 8 | 35 rpm | 6-7 ppm | 4261 | 3217 | 2561 | 1875 | |

| Second period | 4 | 1 kg | 6 | 23 rpm | 6-7 ppm | 4236 | 4247 | 3360 | 2937 |

| 5 | 1 kg | 7 | 35 rpm | 0 ppm | 4230 | 4239 | 4130 | 3861 | |

| 6 | 1 kg | 8 | 14 rpm | 4-5 ppm | 4259 | 3730 | 2048 | 1769 | |

| Third period | 7 | 2 kg | 6 | 35 rpm | 4-5 ppm | 4283 | 3995 | 3842 | 2997 |

| 8 | 2 kg | 7 | 14 rpm | 6-7 ppm | 4276 | 3760 | 1420 | 663 | |

| 9 | 2 kg | 8 | 23 rpm | 0 ppm | 4280 | 4327 | 4323 | 4330 |

Regarding Table 4 and comparing it with Table 2, we easily find that TDS changes are directly related to COD variations. Lower the opacity of the sample has resulted in the lower the COD content. For example, in Test # 2, the system’s viscosity decreases from 4208 to 967, while COD was a downgrade from 5393 to 1275.

However, in cases where purification is not well done, the turbidity has not changed much. Even in some cases it has increased. For example, in experiment No. 9, TDS was 4280 on the first day and reached 4330 on the final day. Also, the biological treatment in this experiment was zero. In sum, the results indicated that the direct relationship between these two experiments was in the biological treatment of sludge.

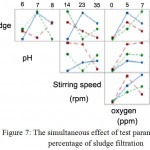

An overview of the simultaneous effect of two parameters on purification

Using the data obtained from each test and the Mini-Tab software to obtain the simultaneous impact of the effective parameters in the experiments on each other, the linear diagram 5 and the two-dimensional diagrams in part 6, 7, 8, 9, and 10 were examined each of them.

|

Figure 7: The simultaneous effect of test parameters on the percentage of sludge filtration

|

Figure 7 shows linearly the simultaneous effect of the four active sludge parameters on the pH of the stirring rate and the oxygen content of two to two percent on the percentage of biological sludge treatment. To better analyze each of them, we use the two-dimensional diagrams in the following sections.

|

Figure 8: The simultaneous effect of mixing rate and pH on the percentage of sludge purification

|

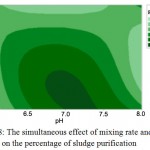

Effect of simultaneous stirring speed and pH

According to the sixth-dimensional diagram, we find that in the range of stirring speeds of 14 to 22 rpm and pH is between 6.8 and 7.3, we can achieve up to 80% filtration. It is also clear that at a speed of 14 rpm, the appropriate pH range for treatment above 80% is between 7 and 7.4. But at a speed of 20 rpm, the pH is between 6.8 and 7.2, which means that the proper pH range decreases with increasing stirring speed.

|

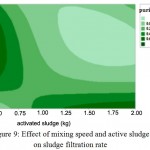

Figure 9: Effect of mixing speed and active sludge on sludge filtration rate

|

Effect of Simultaneous Stirring Speed and Activated Sludge

By observing the 7-D diagram, it is clear that only two areas can be treated near 80%. At a speed between 14 and 15 rpm and active sludge between 1.25 and 2 kg and the other at speeds of 20-30 rpm and activated sludge between 0.5 and 0.6 kg. It is also known that the rate of stirring and the amount of active sludge are inversely proportional to each other, that is, at high speeds, low active sludge levels are appropriate, and vice versa.

|

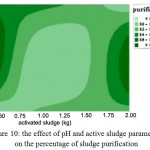

Figure 10: The effect of pH and active sludge parameters on the percentage of sludge purification

|

Simultaneous Effect of pH and Active Sludge

Looking at the two-dimensional diagram of 8, it can be said that in the two regions, it is possible to achieve near 80% filtration with the difference that both of these regions have a pH close to each other. The first area in the amount of activated sludge is between 0.5 to 0.6 kg, with a pH between 6.7 and 7.7, and the second is in the active sludge range of 1.8 to 2 kg and the pH is between 6.4 and 7.4.

|

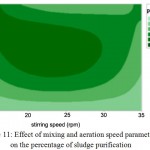

Figure 11: Effect of mixing and aeration speed parameters on the percentage of sludge purification

|

Effect of Simultaneous Agitation and Aeration

After analyzing the two-dimensional diagram9, it can be said that in the concentration range of oxygen dissolved between 3 and 7 mg / L, it is possible to achieve a treatment close to 80%. But with the difference that in the concentration range of oxygen dissolved between 3 and 5 milligrams, the kneading speed should be between 19 and 29 rounds per minute. But in the concentration range of oxygen dissolved between 5 and 7 mg / L, the kneading speed should be low and about 14 to 17 rounds per minute. So, we conclude that by increasing the amount of aeration, the speed of kneading should be reduced, perhaps because oxygen is better at all high-velocity points at high speeds.

|

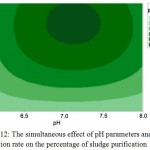

Figure 12: The simultaneous effect of pH parameters and aeration rate on the percentage of sludge purification

|

Simultaneous Effect of pH and Aeration Rate

By observing the two-dimensional diagram, 10-5, it can be concluded that a circle with a pH of 6.8 to 7.4 and a dissolved oxygen concentration of 4.8 to 7 mg / l can achieve a higher than 80% filtration. However, the larger the extent of this circular shape, the amount of purification is reduced. Therefore, we conclude that pH and aeration rate is two of the most important and most effective parameters of bio-sludge purification of sludge.

The Effect of Active Sludge and Aeration Rates

After seeing the two-dimensional diagram, we find that the best treatment for nearly 80% in two regions is completely independent of the amount of active sludge and oxygen concentration. These ranges are one in the concentration of oxygen between 3 and 6 mg / L with active sludge levels between 0.5 and 0.75 kg / g.

With the increase in active sludge, the oxygen concentration range decreases, while the other is within the range of oxygen concentration between 6 and 7 mg / L and the active sludge is between 1.75 and 2 kg which should increase the amount of aeration by reducing the active sludge from 2 kg.

|

Figure 13: Effect of all test parameters on color sludge purification

|

By observing Fig. 11, we can say that the best condition for the test parameters is equal to 7 = pH, Kg 0.5 = active sludge rpm 14 = stirring speed ppm 5.5 = concentration of dissolved oxygen in which the optimum solution can easily be obtained by treating more than 80% sludge from about 83 to 85%. Due to the massive amount of sludge residue in different industries in the world and the high cost of disposing of this waste in the usual way, it can act as an excellent solution and in the future, using it in different industries is reduced one of the environmental problems of the world.

Conclusion

Finally, by examining all the effective parameters in this research, and putting all the results obtained from the effect of these parameters on each other, using the Mini- Tab software, we can reach the linear diagram (12.5). This chart represents the optimal amount of test parameters.

References

- Khezri, Mostafa S, Blourchian A, Monouri A, Masoud S, Farideh A. Contaminants from paint operations in the automotive industry. 2009.

- Fallahpour, Reza M. Determination of optimal method for removing nitrate and carbon from organic matter by A2 / O method in active sludge process, Water and Electrical Engineering University (Shahid Abbaspour, Faculty of Water Engineering, Department of Water and Wastewater Engineering. 2008.

- Vahshvor B, Mahdizadeh A.S, Fallaghnejadtefi N, Amraei R, Hossein M.M, Lokzadeh M. Investigating the Effect of Combined High-Energy Electron Beams and Activated Sludge System on Textile Waste Drainage and Dyeing, 19th Nuclear Conference. 2013.

- Mostafa S, Azadeh K, Bloorchian A, Masoud S.M, Atabi F. Color contamination from automobile industry, environmental science and technology. 2009 Number;16. Spring 93.

- Farahani M. Investigation and Organizing of Environmental Problems of Automobile Industry Waste, Fourth Conference on Environmental Engineering. 2010.

- Bahman M. Performance Evaluation of Active Sludge in Sewage Treatment, National Conference on Water and Wastewater Engineering. 2012.

- Malarzai, Mohammad. Introduction to the design of experiments by Taguchi, Scientific Association of Industrial Engineering, Islamic Azad University. 1392.

- Moradkhani d, Taqwa. Knowledge of Taguchi Kata Experimental Design Methodology. Zanjan University Press. 2007.

- Dakht A,Reza A. Biological Wastewater Treatment Plant, WATER AND WASTEWATER ENGINEERING SCIENCE. 1395.

- Keharia H., Madamwar D. Bioremediation concepts for the treatment of dye containing wastewater: A review. Indian journal of experimental biology. 2003;41:1068–1075.

- Ruffino B., Zanetti M.C. Reuse and recycling of automotive paint sludge: a brief overview, DITAG, Land, Environment and Geo-Engineering Department, 10129 Torino, Italy. 2011.

- Sedlak R.I. Phosphorus and Nitrogen Removal from Municipal Wastewater, The Soap and

DetergentAssociation, Lewis Publishers, 2d ed., New York. 1991. - Waser J. Heterocyclic Chemistry Award, Young Swiss scientist honored for his outstanding research, establish by Springer. 2016.

- Robert R.M, Dennis M.D, John R.M, David A.F. Process for producing building materials from raw paint sludge, E.I. Du Pont De Nemours And Company, CN1564792A. 2006.

- Salihoglu G.N Salihoglu K. 2016, A review of paint sludge from automotive industries: Generation, characteristics and management. Journal of Environmental Management. 2016 March 169;(15):223-235.

This work is licensed under a Creative Commons Attribution 4.0 International License.