How to Cite | Publication History | PlumX Article Matrix

Analysis Of Total Carbohydrate Content Of Single Cell Protein Produced By Utilising Okara

Shaukat Saeed Khan, Mahmood Khan Yousufi and Mohammad Neyametullah Khan

Department of Microbiology, Saifia College of Science and Education, Bhopal - 462 001 (India)

ABSTRACT: Okara is a byproduct of soymilk industry, annually it is produced in large quantities. Okara acts as a waste for soymilk industries and possess a big disposal problem. In the present investigation Okara was used in three different combinations along with wheat grits. In the first combination 3 parts of Okara and 1 part of wheat grits was used, in the second combination 1 part of okara and 1 part of wheat grits was used and in the third combination 1 part of Okara and 3 parts of wheat grits was used. The three combinations were inoculated with two food fungi viz. Rhizopus oligosporus and Aspergillus oryzae respectively for producing single cell protein. The single cell protein produced in the three combinations was analysed for the total carbohydrate content. The maximum carbohydrate content was obtained with combination of 3 parts of Okara and 1 part of wheat grits, incase of both Rhizopus oligosporus (4.98%) and Aspergillus oryzae (5.02%).

KEYWORDS: Single Cell Protein; Total Carbohydrate content; Okara

Download this article as:| Copy the following to cite this article: Khan S. S, Yousufi M. K, Khan M. N. Analysis Of Total Carbohydrate Content Of Single Cell Protein Produced By Utilising Okara. Biosci Biotechnol Res Asia 2003;1(1) |

| Copy the following to cite this URL: Khan S. S, Yousufi M. K, Khan M. N. Analysis Of Total Carbohydrate Content Of Single Cell Protein Produced By Utilising Okara. Biosci Biotechnol Res Asia 2003;1(1). Available from: https://www.biotech-asia.org/?p=3386 |

Introduction

In the modern world fermentation technology is used for large scale culture of microorganisms which can be used as a direct source of high protein food, and is known as single cell protein (SCP). Suitability of SCP for feeding human beings has been studied by Kacmpfel et al., (1995)4. An obvious use of fermentation technology is processing of byproducts (waste products) obtained from industrial and agricultural products. In the present investigation okara was used, which is a byproduct of soymilk industries. The high moisture content of okara makes it unsuitable to be utilized (Shurtleff and Aoyagi, 1979)10. However, nutritional composition of okara favours its utilization. It contains 76.6% moisture, 19.91% protein, 8.37% oil, 9.53% carbohydrate and 2.82% starch. Major minerals like calcium, iron, copper and zinc also increases its nutritive value.

Okara has been used by various investigators for producing different fermentation products. Fujiwara and Takemoto (1996)2 studied the composting method for tofu refuse (okara), using an air tight composting plant. Matsuo, M. (1997)6 has reported the in vivo antioxidant activity of okara by A. oryzae. Fuh-Juin Kao et al., (1998)3 has reported the fermentation of okara by lactic acid bacteria, with the addition of molasses and macerating enzymes. Miyamura et al., (1998)7 examined the fibrinolytic activity of natto produced from okara fermented with Bacillus subtilis. A process was developed for preparing better quality soymilk and okara by Nishimura et al., (1998)8. Kinoshita et al., (1985)5 has used okara for the production of riboflavin and lipase. Sawano (1999) has developed a process for producing functional okara milks and functional tofu from okara. Yousufi et al., (2003) produced SCP using okara, by controlling its moisture content.

Taking the above evidences into consideration, an attempt was made in the present investigation to produce SCP by using okara and analyse its carbohydrate content.

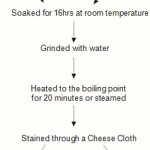

The production of okara and soymilk is described in Figure 1. Okara and wheat grits were mixed in three different ratios to produce the following three combinations.

|

Scheme 1 |

Table 1 : Combinations of Okara and wheat grits

| S. No. | Combination | Okara Wheat grits | |

| ratio | (g) | (g) | |

| 1. | 3:1 | 150 | 50 |

| 2. | 1:1 | 100 | 100 |

| 3. | 1:3 | 50 | 150 |

The combinations of Okara and wheat grits were filled in petriplates, which were autoclaved. The combinations were then inoculated with two food fungi viz. R. oligosporus and A. oryzae respectively. The inoculated combinations were thereafter incubated until white cottony mycelium is produced on them. After this samples were removed from each combination and analysed for the total carbohydrate content. The total carbohydrate content was determined by AOAC method (1984).

The total carbohydrate content in different combinations, in case of R. oligosporus and A. oryzae are given in Table 2 and 3 respectively.

Table 2 : Total carbohydrate content in the three combinations with R. oligosporus

| Organism | Okara/ | Total |

| wheat grits | Carbohydrate | |

| Content | ||

| (in grams) (per 100g substrate) | ||

| R. oligosporus | 150/50 | 4.98 |

| 100/100 | 4.95 | |

| 50/150 | 4.90 | |

Table 3: Total carbohydrate content in the three combinations with A. oryzae

| Organism | Okara/ | Total |

| wheat grits | Carbohydrate | |

| Content | ||

| (in grams) (per 100g substrate) | ||

| A. oryzae | 150/50 | 5.02 |

| 100/100 | 5.01 | |

| 50/150 | 4.99 | |

The results in the Table 2 depicts that the combination of 3 parts of Okara and 1 part of wheat grits contained maximum carbohydrate content (4.98%), with R. oligosporus. The results in Table 3 depicts that the combination of 3 parts of Okara and 1 part of wheat grits contained maximum carbohydrate content (5.02%), with A. oryzae. Hence, the combination ratio 3;1 shows maximum carbohydrate content for both R. oligosporus and A. oryzae.

Acknowledgement

The authors are thankful to the authorities of Saifia College of Science and Education, Bhopal for providing laboratory and library facilities during the tenure of the present investigation.

References

- Official methods of Analysis of the association of official agricultural chemists, 14th ed., Minnesote, USA (1984)

- Fujiwara, S. and Takemoto, M. Study on unused resources for use as manure. A composting method for tofu refuse (okara) using an air tight type composting plant. Bulletin of the agricultural research institute of Kanagawa Prefective No. 137, 25-34 (1996)

- Fuh-Juin Kao, Mee-Ling Leu; Wen-Lian Chen and Wei-Chong Tsai. Preservation of Soybean byproducts lactic acid fermentation of Okara. Food Science, (Taiwan) 25, 787-798 (1998)

- Kacmpfel, U., Berghausen, K.H. and Lieflander, M. Are Cyanobacterio suitable for feeding human beings? A contribution on essential amino acids of Cyanobacteria. Deutsche lebensmitted – Rundschau, 91(2), 50-50 (1995)

- Kinoshita, S. Kittikun, H. A. and Pithong R., Production of Riboflavin from waste of tofu (Soycurd) Annual Report IC Biotechnology, 8, 322-324 (1985)

- Matsuo, M. In vivo antioxidant activity of Okara kogi, a fermented okara by Aspergillus oryzae. Bioscience Biotechnology and Biochemistry, 61, 1968-1972 (1997)

- Miyamura, H., Takenaka, Y. and Takenaka, T., Fibrinolytic activity of okara fermented by Bacillus subtilis, II. The utility of okara, a byproduct of soybean processing industry. Journal of Japanese Society of Food Science and Technology (Nippon Shokuhin Kagaku Kogaku Kaishi), 45, 100-107 (1998)

- Nishimaru, T., Nagaoka, S., Sugano, H. and Tsumura, H. Process for producing soybean milk and okara (patent) European Patent Application EP0875 151 A2 [JP97-11352 (970501]) [Fugi oil, Osaka, Japan] (1998)

- Sawano, E.H. Process for producing functional okara milks and functional tofus [patent] (Sawa industrial Co. Ltd.) PCT International Patent Application WO 99/ 41999 AI [JP 98-39319 (199802200)] Sawa Industrial, Yamaguchi, 757-0216, Japan (1999)

- Shurtleff, W. and Aoyagi, A. Tofu and Soymilk production. New Age food study centre, Lafayette, CA, USA (1979)

- Yousifi, M. K., Khan, S. S. and Jha, Krishna, The effect of moisture content on the production of single cell protein using Rhizopus oligosporus and Aspergillus oryzae grown on okara – wheat grit Indian J. Applied & Pure Bio., 18(1), 81-84 (2003)

This work is licensed under a Creative Commons Attribution 4.0 International License.