Manuscript accepted on : 20-02-2023

Published online on: 13-03-2023

Plagiarism Check: Yes

Reviewed by: Dr. Ali Mohamed Elshafei

Second Review by: Dr. Robert Susło

Final Approval by: Dr. Haseeb Ahmad Khan

Nanotechnology in Plastic Degradation

R Rameshwar Chandran , Benjamin Isaac Thomson

, Benjamin Isaac Thomson  , A. J Natishah

, A. J Natishah  , Jennita Mary

, Jennita Mary  and Valli Nachiyar *

and Valli Nachiyar *

Department of Biotechnology, Sathyabama Institute of Science and Technology, Chennai, Tamil Nadu, India.

Corresponding Author E-mail:vnachiyar@gmail.com

DOI : http://dx.doi.org/10.13005/bbra/3068

ABSTRACT: Plastics pose a huge threat to the environment. Plastic accumulation in the land and the seas is now the world’s most terrorising problem, mainly because of its non-degrading character. Plastic degradation has always been a next to impossible concept in the field of science, but nanotechnology provides a revolutionary and modern way to solve the problem of plastic accumulation in the environment. One of the great advantages of nanoparticles is that we can increase and decrease the rate of biodegradation depending on our needs. Nanoparticles enhance the polythene degradation capacity of the microorganisms by altering their metabolic cycles. Numerous studies showed conclusively that the incorporation of nanotechnology enhances the ability of microorganisms to degrade polythene materials. Even though bio degradable plastics are nowadays produced in large quantities to substitute polythene materials, they fail to match the brittleness of plastics. Biodegradable plastics have poor thermal, mechanical and low gas barrier qualities, which are their main drawbacks. To overcome this, nanoparticles are incorporated into the biopolymers. If an appropriate balance between nanotechnology, microbiology and biotechnology is found, plastic degradation can be done economically and feasibly in all the areas.

KEYWORDS: Biodegradation; Biopolymers; Degradation; LDPE; Nanomaterials; Polymers

Download this article as:| Copy the following to cite this article: Chandran R. R, Thomson B. I, Natishah A. J, Mary J. Nanotechnology in Plastic Degradation. Biosci Biotech Res Asia 2023;20(1). |

| Copy the following to cite this URL: Chandran R. R, Thomson B. I, Natishah A. J, Mary J. Nanotechnology in Plastic Degradation. Biosci Biotech Res Asia 2023;20(1). Available from: https://bit.ly/3lgdn2F |

Introduction

Plastics have been around for a long time, helping humankind in all fields of life. Plastics are useful substitutes for any material, because of their sturdy, brittle nature. Although plastics carry an immeasurable number of advantages, it is termed mankind’s worst creation. The problem with plastics is that they cannot be degraded by natural methods. Conventional or chemical or thermal methods consume a lot of energy to degrade plastics and also create a hefty number of problems after the completion of the degradation process. The by-products after the conventional degrading processes of plastics are also very harmful to the environment. In most places, plastic is not degraded in a proper way, because of its high capital requirement for degradation. They are dumped in open pits, or piled up as huge mountains, only to remain there untouched for the next hundred years. Nanotechnology has been around for more than two decades and is starting to expand to every known science of life, because of its broad capabilities and extraordinary capacity. The field of plastic degradation is no exception. Nanotechnology not only provides a sustainable and eco-friendly solution to plastic degradation problems but also has the ability to do it in a cost-effective mechanism. Several methods of plastic degradation are discussed in this chapter, along with the replacement for plastics, the alternatives offered by biopolymers and their efficiency in completely replac ing the dominant force of pollution in our environment. Nanotechnology also created a positive impact in this field in the production of brittle, thermally stable biopolymers to overthrow conventional plastic products. The problems posed by plastics to the open world are challenging and everlasting, the enlightening answer given by the science to the human race is nanotechnology.

Environmental Problems

Plastic now plays a crucial part in daily life and is an inescapable substance. They are mostly composed of carbon at the atomic level.2 They have connected chains of hydrocarbons with nitrogen, sulphur, and oxygen that are organic polymers with high molecular weights. Plastics are persistent and take a long time to degrade.1 Plastics are typically produced from synthetic polymers by adding different chemical additives.3

In terms of plastic debris, there are two types: primary and secondary types. When recovered, primary plastics remain in exactly the same condition as when they were first made. These include bottle tops, microbeads, and cigarette butts. Smaller polymers that are produced as a result of the deterioration of primary plastics are referred to as secondary plastics.4 It is technically true that rubbers and plastic are both polymeric materials.5 Synthetic polymers are often synthesized by crosslinking monomers sourced from oil or gas. Currently, there are over 20 main categories of polymers, with each offering a wide range of qualities and variations. The variety of polymers and the scalability of their characteristics enable the manufacturing of a wide range of plastic items that provide advanced technologies, efficiency improvements, and a host of other inherent advantages.3 Our knowledge of plastics in ecological systems may be enhanced by recognising plastics as granular materials and utilising geochemical ideas and tools.2

The significance of plastic in contemporary civilization is without question.5 Plastic is a cheap, durable material that is used to make a large portion of the goods we consume. But because of the chemical makeup of plastic, it takes a long time for it to wear down, which is a real concern. It is critical to decrease plastic usage and increase awareness about plastic recycling since we have relied on plastic as an inexpensive, adaptable, and long-lasting material since the late 20th century.6 Plastics, which may be degraded into micro- or Nano-plastics are fundamental and durable materials utilized in daily life.7 Over the following two decades, their output is anticipated to double.8 Despite the fact that the current public attention on plastics has mostly focused on issues related to human health and the environment, plastics continue to help society in a variety of ways. In comparison to other materials like metal or glass, plastics are more adaptable, more affordable, need less energy to make, and can be designed to have a wide range of qualities.9 Plastics have altered our daily lives over the last few decades. We consume over 260 million tons of plastic annually on a worldwide platform, which is roughly comparable to 8% of the world’s oil and gas production. Plastics offer multiple advantages for humankind. But there are many implications that a build-up of waste plastic will have on the environment; the impact it will have on ecology, and the health risks associated with the manufacturing, disposal of plastics, etc.3

The collection and fragmentation of plastics are one of the recent surface changes to our planet that have been most pervasive and permanent. Plastics normally make up about 10% of the trash that is thrown away. According to estimates, plastic can survive for hundreds to thousands of years. It poses a significant threat because it starves and suffocates wildlife, fosters exotic and potentially deadly species, absorbs poisonous chemicals, and breaks down into tiny plastic particles that can be swallowed subsequently.10 Global plastic manufacturing surpassed 280 million tonnes in 2016. Neither recycling nor landfills obtained more than half of it.11 Wildlife and our environment are being physically destroyed by plastic due to the accumulation and poor recycling. Many plastics might potentially be chemically detrimental in certain situations, either because they could themselves be hazardous or because they could absorb other impurities.11

Plastic Accumulation

Let us discuss about plastic waste in detail. It alludes to the enormous quantity of plastic that isn’t recycled and winds up in garbage dumps or, in the poor world, is discarded at uncontrolled dump sites.6 Plastic debris produces heat and CO2 when it is burned or dumped in landfills.12 When plastic was widely used and behaviours were altered, major issues including an increase in garbage build-up resulted from these factors. When plastic waste is not properly disposed of, environmental problems which are also known as socio-environmental problems are created or made worse. These problems impair the health of the people.5

|

Figure 1: Desegregated plastic wastes pose a major threat |

Small urban streams and more than 1,000 rivers are thought to be the sources of 80% of the world’s annual carbon emissions, which range from 0.0008 billion to 0.0027 billion metric tonnes.13 Over 90% of the 8.3 billion tonnes of plastic produced since the start of widespread manufacture of plastics over 60 years ago are not recycled. As of 2018, over 380 million tonnes of plastic are manufactured annually worldwide. Environmental calls to minimize plastic pollution and consumerism have become more urgent in recent decades due to the fact that our world cannot uphold this level of plastic contamination.6 It was estimated that 60 percent of all plastics produced to date have been disposed of in landfills or the environment.13The invention of Bakelite in 1907 caused a patterned shift in materials by introducing entirely synthetic plastic resins to the world economy. At the turn of the 20th century, scientists learned that plastics could withstand poisonous elements from Mount Everest to the bottom of the ocean. Plastics are now widely acknowledged to be a major annoyance, whether it is because animals mistake them for food, they clog sewage systems and flood low-lying areas, or just because they look terrible.14

|

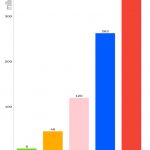

Figure 2: Plastic production by the world over the years |

Source: Our World in Data based on Geyer et al. (2017) and the OECD Global Plastics Outlook

Alterations to the carbon and nitrogen cycles, ecological modifications in lands, sediments, and aquatic environments, and concurrent biological effects are all potential effects of non-reversible plastic pollution.15 To achieve economic growth and protect the environment, technology and society must advance together.5 The cycle of making and discarding plastic will continue unless companies begin to use more eco-friendly, alternative materials (like bamboo, bioplastic, etc.).6 Companies may invest in technology that supports a circular economy since there is a commercial reason for doing so, in addition to customer pressure for brands to be more environmentally conscious.16 A combination of human activity and natural occurrences results in the daily discharge of millions of tonnes of pollutants into the atmosphere. Chemicals that harm a population’s health, behaviours, or capacity for survival are considered pollutants. These pollutants that humans discharge into the environment are significantly more dangerous.4 To prevent illnesses from endangering environmental stability and social livelihoods, it is essential to control pollutants from plastic trash.17 In the marine ecosystem, plastic garbage is amassing more and more.18

Plastic Threat to Living Species and Environment

Environmental plastic pollution is a widespread issue.2 Plastics are becoming more prevalent in all forms of the environment, including different ecosystems and the atmosphere.19 Humans have the power to jeopardize both the ecological environment and humankind. This arises when plastic materials, such as plastic containers and polythene bags, are used for packing, and then, after usage, it is discovered that they were carelessly thrown away without contemplating the consequences. It takes a long time for most plastics to decompose because of their chemical composition, which makes them very durable to many ecological causes of breakdown.4 Regular waste management procedures are put under additional stress by the global health crisis, which results in the use of unsuitable management techniques like mobile burning, direct dumping, and local incinerating.20 As the world’s population expands tremendously, so does the need for plastic, sometimes without consideration for the repercussions of its usage or disposal. The plastics that are contaminating the environment have sizes ranging from enormous to fairly small. Plastics are available in various forms. Everyday rubbish, how plastic and trash are disposed of, and excessive plastic use are the primary causes of plastic pollution.8 During the outbreak, personal protective equipment (PPE) has been linked to an increase in plastic pollution. As a result of the rising demand for PPE among many members of the general public, healthcare workers, and service workers, mono-use face mask production in China climbed to 0.11 billion in a day in February, over 12 times the typical quantity. After lockdowns cease, if everyone in the world uses one temporary surgical mask per day as a norm, the pandemic may lead to a 129 billion disposable face masks and 65 billion disposable gloves monthly consumption and waste.20 The best tactics for reducing the negative effects caused by the widespread issue of plastic pollution are still uncertain. Even with the optimistic outcome, enormous amounts of plastic will still build in the ecosystem despite quick, persistent, and forceful action leading to significant reductions in the output of plastic waste.22 Numerous environmental issues are caused by plastic.12 The only way to respond to plastic pollution is to reduce the use of plastics as well as to reduce the emission of plastic materials into the environment.15 To meet existing environmental and social responsibility obligations, businesses should keep working to reduce the consumption of virgin plastic and promote plastic recycling.20 To replace harmful compounds contained in some plastics, such as endocrine disruptors, a science-based strategy is required.8 Targeting the whole plastics life cycle enables a more equal allocation of the expenses and benefits of pertinent activities along the value chain globally.19 One of the greatest sinks for marine plastic pollution is thought to be the retention of plastics in sediments, which might explain the surprisingly low amounts of plastic detected in water bodies.21 Most plastics in the marine ecosystem are considered to be disposed of in sediments. Plastic material is particularly persistent in seawater due to its intrinsic durability, where it breaks apart but does not deteriorate. Microplastics, or particles with a diameter of less than 5 mm, as a result, are steadily building up over a large portion of the seas.21 Order of hundreds of hundreds of tons of plastic are estimated to be floating at the ocean’s surface, which is a very minor amount compared to the several million tonnes that are thought to be released annually by rivers.23 When plastic debris enters aquatic bodies, it becomes much more hazardous. According to research on the causes and consequences of plastic contamination in aquatic settings, territory polymers are one of the primary contributors to marine plastic contamination.18

|

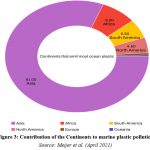

Figure 3: Contribution of the Continents to marine plastic pollution |

Source: Meijer et al. (April 2021)

Coral reefs are essential for coastal protection and fisheries, and they desperately need to be protected from the harmful consequences of plastic trash. The coral reefs are interwoven with billions of pieces of plastic. Due to light restriction, toxicity secretion, and oxygen depletion caused by plastic debris, coral is under stress, which provides a platform for pathogen invasion. The amount of plastic garbage found on coral reefs is in line with estimates of the amount of plastic waste generated on land that ends up in the ocean.17 An increasing number of nations and non-profit organizations are calling for a new global convention in the midst of the problem of plastic pollution.19

Marine animals that become entangled in plastic items like nets can suffer pain, damage, and possibly pass away. Over 260 various species of animals have been reported to consume plastics or become entangled in plastic or plastic-related goods. In an assessed 243 species of aquatic life, entanglement has been found to pose health hazards that frequently result in mortality. Derelict fishing nets, sometimes known as “ghost nets,” frequently catch marine creatures, causing malnutrition and death.

In spite of the fact that polymers are quite beneficial in daily life, it is important to closely monitor the harmful chemicals used to protect the environment and human health.24 Microplastics are plastic granules with a diameter of 5 millimeters or less. Nano plastics are polymers that are up to 100,000 orders of magnitude smaller than a millimeter. In our environment, microplastics have been discovered everywhere, even in the deepest ocean trenches. Additionally, microplastics are present considerably closer to home. Microplastics are pervasive in almost every home since they are emitted from our couches, rugs, drapes, and other textile polymers.

Only 0.1 percent of the 288 million tonnes of plastic produced year, or just over the annual vegetable harvest, is detected in the ocean using existing technologies. The most evident manifestation of this trashed plastic is the ugly waste that washes up on our beaches. Plastic nanoparticles can really be internalized at the level of particular cells, but their interaction with marine life is not yet fully understood. Indeed, because of their effectiveness in ensuring that the proper medication is taken into the appropriate cells, nanoparticles are being investigated for use in drug administration.

Nanoparticles

Nanotechnology is a multifaceted field of science that plays with physics, chemistry, biology and other engineering sciences. Materials which the external dimension that measures 100 nanometres or less. They may be in the form of tubes, particles, rods, and fibres. Nanomaterials are present in various fields of science like agriculture, medicine, environment, energy production, etc.25

Nanomaterials are classified into four kinds. They are (1) inorganic-based Nano materials, (2) carbon-based nano materials, (3) organic-based nano materials, (4) composite-based nano materials. Inorganic nano materials are generally metal and metal oxide nano materials. Some examples of metal based inorganic nano materials are silver (Ag), aluminium (Al), cadmium (Cd), iron (Fe), and gold (Au). They can be divided into many categories, such as metal NPs, metal-oxide NPs, bimetallic NPs, trimetallic NPs, and others. Compared to bulk materials, some metal NPs, including Au and Ag, have exceptional optical, electrical, and chemical properties because of their smaller particle size, increased surface area, and reactivity. Carbon-based nanomaterials are grapheme, fullerene, single-walled carbon nanotubes, multi-walled carbon nanotubes, carbon fibre, and carbon black. Most frequently seen in the shape of hollow spheres, ellipses, or tubes, these nano materials are primarily made of carbon. Carbon nano materials that are spherical, elliptical, or cylindrical are referred to as fullerenes. Numerous possible uses for these particles exist, including enhanced films and coatings, stronger and lighter materials, and electrical applications. Organic nanomaterials are usually created from organic materials like dendrimers, liposomes, micelles etc. These do not include carbon materials. Composite based nano materials are the nano materials that have complicated structures like metal-organic framework. Nanoparticles can be combined with other nanoparticles or with larger, bulkier elements to create composites. To improve the mechanical, thermal, barrier, and flame-retardant qualities of items ranging from auto components to packaging materials, nanoparticles, such as nano sized clays, are already being used26.27. It has been successful to synthesize nanomaterials using a variety of biomolecules, including proteins, lipids, polysaccharides, nucleic acids, and others. Despite not previously being as well-known as inorganic nanoparticles, these materials have drawn considerable attention as a result of the growing use of biocompatible and biodegradable nano materials. The main area of application for such materials is drug distribution. Because of their capacity for self-assembly, biomolecules like DNA and proteins play a key role in the creation of a variety of nanostructures with uses in the biomedical industry and other sectors. These materials have significant potential as futuristic nanomaterials. Furthermore, they have the capacity to mix with inorganic nanomaterials to form complexes to produce hybrid materials that combine the best features of both types of substances. For instance, nanoparticles attached to nucleic acids improve molecular recognition in biosensing28,27. Depending on their sizes, particles can be further divided into the following types:

Ultrafine particles, which have sizes between 1 and 100 nm, are comparable to nanoparticles.

Small, uniform particles with a size of 100–2500 nm.

Large particles with sizes ranging from 2500 to 10000 nm.29

Depending on the nature and kinds of nanomaterials, multiple synthesis techniques can be used to create them. Top-down and bottom-up approaches are the two most common approaches. To make nanomaterials, bigger bulk molecules are broken down into smaller particles using a top-down technique.25 The following list of typical top-down processes includes mechanical ball milling, arc discharge, wire explosion, lithography, laser ablation, and other examples. Top-down strategies gain from easily accessible, well-established equipment and straightforward methods. The fundamental problem with top-down approaches may be related to the expensive instrumentation required and the faulty structures that are produced. When using a bottom-up method, nanomaterials are developed from their basic level. Typically, a chemical reaction that produces nanostructures aids in this process. It is comparable to building a house from the ground up using bricks as construction components. Examples of bottom-up approaches include chemical reduction, photochemical synthesis, sol-gel synthesis, hydrothermal or solvothermal synthesis, chemical vapour deposition, coprecipitation, biological processes, and more. Improved NP size control, fewer structural faults, homogeneous chemical composition, minimal cost, and straightforward scaling are these technologies’ main advantages. The key drawbacks include the need for suitable surfaces and molecules, as well as the limited scope for atomic and molecular manipulation26,27 .

Nanomaterials have unique properties which can gain by tuning the sizes and morphologies of nano materials. The surface areas of nano materials are generally greater compared to their bulk materials. The magnetic property of elements usually changes at nanometre. A non-magnetic material may change into magnetic at the nano level. Thus, almost all nano materials exhibit magnetic properties. Certain nano materials possess anti-microbial and anti-fungal characteristics that provide them with the capability to deal with studies related to pathogens.27 Due to a high portion of surface atoms in the total number of atoms, nano materials may have a much lower melting point or phase transition temperature and appreciably lower lattice constants. Nanomaterials’ optical characteristics can be very different from those of bulk crystals. For instance, a semiconductor nanoparticle’s optical absorption peak changes to a short wavelength as a result of an expanded band gap. Due to surface plasma resonance, the colour of metallic nanoparticles may vary with their sizes. The mechanical properties of nanomaterials have theoretical strengths that are one or two orders of magnitude greater than single crystals in bulk. The decreased likelihood of faults is the only factor contributing to the improvement in mechanical strength. As a result of increased surface dispersion, electrical conductivity decreases with decreasing dimension. However, improved ordering in the microstructure, such as in polymeric fibrils, could also significantly increase the electrical conductivity of nano materials.30

Nano materials have a wide range of applications in various fields. Nanomaterials have a variety of significant uses, including in the fields of aerospace and chemical engineering, optics, solar hydrogen, fuel cells, batteries, sensors, power generation, building and construction, automotive engineering, consumer electronics, thermoelectric devices, pharmaceuticals, and the cosmetics industry. In order to perform effectively, nanoparticles are now used in a wide range of cosmetics and sunscreens. It is yet unclear whether or not the nanoparticles present in these items are harmful to human health. Zinc nanoparticles are not absorbed in vivo into the bloodstream, according to studies on their use. Nanomaterials can be modified to carry out a variety of specialized tasks. By fusing the nano materials with other proteins or structures, this can be accomplished. The nano materials can be used for both in vitro and in vivo biomedical research and applications since they are similar in size to different biomolecules and structures. Nanomaterials and biology have so far been combined to provide a variety of diagnostic instruments, contrast agents, analytical tools, physical therapy applications, medication delivery vehicles, etc. Nanoscale fabric surface treatments or additives can provide lightweight ballistic energy deflection in personal body armour and help materials resist bacterial development, wrinkling, staining, and other problems. Surfaces that are water- and residue-resistant, antireflective, self-cleaning, resistant to UV or infrared light, antifog, antibacterial, scratch-resistant, or electrically conductive can all be made using clear nanoscale coatings. Carbon nanotube sheets are now being produced to utilize them in the most recent air vehicles. For instance, their small weight and conductivity make them perfect for uses like heat control and electromagnetic shielding. Due to nanotechnology, clinical practitioners currently have access to a broader variety of medical tools, knowledge, and therapies. By utilizing the inherent scale of biological activities, the application of nanotechnology in medicine or nano-medicine yields precise solutions for disease prevention, diagnosis and treatment. The lab-on-a-chip technique is comparable to nanotechnology-on-a-chip. A few drops of a patient’s blood could be used to detect and diagnose cancer in its early stages using sensor test chips with thousands of nanowires that can identify proteins and other biomarkers left behind by cancer cells.29,31

Nanoparticles in Plastic Degradation

Plastic pollution is a very serious threat to the ecosystem and other living creatures. There are physical, chemical, and biological solutions to the problem. Conventional biological methods, such as the enzymatic process of plastic degradation, are inefficient because of environmental limits. Engineered nanomaterials are becoming more and more crucial in a variety of sectors, including infrastructure, aircraft, energy generation, and medical uses. However, the deterioration of these materials has the potential to release reactive or dangerous materials into the environment, which can have an adverse effect on performance. The possible mechanisms of environmental degradation, such as oxidation, mechanical wear, chemical, and biological degradation, and loss of protective coatings, provide illustrations of how these factors may affect the durability and environmental transformation of nanoparticles, nanostructured surfaces, and nanocomposites.32 The potential of nanomaterials to improve the effectiveness of currently employed microplastic removal methods and provide creative answers to problems that arise.33 Conventional biological methods, such as the enzymatic process of plastic degradation, are inefficient because of environmental limits. Frequent landfilling and burning of plastic waste diminish the soil’s ability to absorb water, leading to soil sterility. Aquatic organisms gather in streams where plastic garbage is dumped, harming the aquatic biotic systems. Other degradation methods are more time-consuming and less reliable. Since they can hasten the process by influencing the growth of the appropriate microorganisms and serving as superior catalysts for the process, nanoparticles have a special potential for degrading polymers. There are many different sizes and forms of nanoparticles, which can increase physicochemical stability and degradability.34

By combining hydrogen tetrachloroaurate (III) (HAuCl4.3H2O) with the aqueous leaf extract of Ananas comosus, gold (Au) nanoparticles were created. These gold nanoparticles’ photocatalytic activity was revealed when they were exposed to Low-Density Polyethylene (LDPE) films. The LDPE film degraded as a result of this. Under sun radiation, the LDPE film lost 51.4% of its weight in 24 hours. As a result, a new colony in the area of polymer degradation is created.35 Bimetallic core/shell palladium/gold (PdcoreAushell) were extracted from Pd (II) and Au (III) solutions with the help of a reducing agent, the leaf extract of Ananas comosus. The photocatalytic properties of these nanoparticles were exposed when they were introduced into the process of solid-phase of degradation of LDPE film by solar irradiation. After a stipulated period of 240 hours of solar irradiation, the weight of the polymer was reduced by 55.8±5.9%. The nanoparticles also had the power to degrade LDPE films at dark conditions at a degradation rate of 1.90±0.3%. The best part of this process is that the nanoparticles can be reused for up to 5 photocatalytic degradation cycles, without a drop in their efficiency to degrade LDPE films. This opens up a sustainable setup to degrade polymers by newer methods and technologies.39

Yet another research on the photocatalytic degradation property of nanoparticles revealed that zinc oxide nanoparticles (ZnO) when incorporated into LDPE films increased the rate of degradation after irradiating for 200 hours. Moreover, weight loss of the polymer confirmed the photocatalytic activity of ZnO nanoparticles.36 A special experiment conducted under the theme of water purification revealed that zinc oxide nanoparticles (ZnO) synthesized from areca nut (Areca catechu) had the capacity to degrade LDPE films. The degradation was bought by the photocatalytic property of the ZnO nanoparticles. The integration of ZnO nanoparticles with LDPE nanocomposite films brought about the expected results of degradation of the film. This creates a new avenue in the field of water purification, to remediate our rivers from the high potential threats-plastics.38 The photocatalytic degrading activity of palladium nanoparticles was yet again tested by scientists, but this time the palladium was produced in a green-synthesis method by using the leaf extract of Ananas comosus, which played a crucial role as a reducing as well as stabilizing agent. A new method was adopted when LDPE films were exposed along with the modified Pd nanoparticles in solar light under ambient conditions, along with open air for a time period of 30 days. When photo induced weight-loss of the polymer was studied, a massive 49% degrading rate was achieved.40

Plastic wastes like High-Density Polyethylene (HDPE) and LDPE are transformed into Multi-Walled Carbon Nanotubes using a new method (MWCNTs). Harmful HDPE and LDPE can now be used as feedstock for the synthesis of MWCNTs, which are crucial components in many different engineering domains, thanks to thermal dissociation in the presence of chemical catalysts in a closed system under autogenic pressure.37

Interaction Between Microorganisms and Nanoparticles in Polymer Degradation

Microorganisms have always played an inevitable role in biodegradation of polymers. Microorganisms either consume the target material as a substrate or degrade the target material by specific metabolic pathways. The interaction between nanomaterials and microorganisms has always been an interesting research area. The degradation rate of polymers by interacting nanomaterials and microorganisms was higher when compared to their individual degrading capacities. Researchers found that silver nanoparticles (AgNP) generated from Aspergillus oryzae could destroy 64.5% of low-density polyethylene (LDPE) and 44.4% of high-density polyethylene (HDPE) in 5 weeks when applied to LDPE (linear high-density polyethylene) and branching low-density polyethylene. The fluid thinned after being subjected to nanoparticles and polyethylene wax. When the partially deteriorated HDPE was put via FTIR, it was discovered that the C-H bonds, which make up the polymer’s backbone, were bent and stretched.

The degraded LDPE was studied and the formation of phenols, alcohols and ketones was observed, which indicates the breakdown of the polymer. 41 The rate of biodegradation is easily altered with the influence of nanoparticles. In certain biodegradation processes, a toxic environment for microorganisms is created by high chemical deposition. Nanoparticles help to overcome this problem through the development of low-density polyethylene and improve the biodegradation rate by corrupting the microbes.42 The conventional methods of degradation of LDPE produced in the petroleum industries have always been a big problem for environmentalists, as its degradation causes a high level of environmental pollution. These problems can be overthrown by microbial and enzymatic processes of biodegradation. A significant issue is how nanoparticles affect the growth patterns of LDPE-degrading bacteria to speed up biodegradation. For example, Nanobarium titanate is used in the broth to grow and influence the life phases of microorganisms. It works by shortening the lag phase of the degrading microorganisms, lengthening the log phase and stationary phase, and giving the bacteria a faster rate of development. 38 nm is the ideal particle size for bacterial consortia of Microbacterium species strain MK3, Pseudomonas putida strain MK4, and Bacterium Te68R strain PN12.43 Scientists inferred that the incorporation of SPION (super magnetic iron oxide nanoparticles) and Nanobarium titanate (NBT) in the concentration of 0.01% (w/v) in minimal broth considerably increased bacterial growth and also ensuring the early arrival of the exponential phase. This broth had the capacity to degrade LDPE (low-density polyethylene) film in multiple steps. Furthermore, it was also found that the degradation of the film greatly increased when it was incubated with nanoparticles under soil conditions for 3 months. These studies reveal how nanoparticle-bacteria interactions are crucial in influencing key metabolic processes for biodegradation.44 A new research study revealed the influence of nanoparticles in the growth and establishment of polymer-degrading microorganisms. When SiO2 nanoparticles were added to the medium containing LDPE at concentrations of 0.01% w/v, degradation of LDPE was observed. Bacillus sp. strain V8, Pseudomonas sp. strain C25 were found to be the most efficient polymer degraders.

These microbes work by altering the chemical structure of the polymer, which is further confirmed by Fourier transform infrared analysis.45 The incorporation of nanoparticles in growth has always been beneficial to the microbes as it not only reduces the lag phase but also increases the exponential and stationary growth phases, which indirectly increases their biodegradation efficiency. The dissolution of LDPE in the NBT infused medium was greater than compared to the control medium. Thus, it can be concluded that NBT acts as a nutritional additive to the plastic degrading microbes.46 A special research experiment conducted by scientists saw the incorporation of fullerene-60 nanoparticles in a consortium of LDPE-degrading microorganisms. At concentrations of 0.01% of fullerene nanoparticles, the degradation of LDPE was found to be intensified. The results were confirmed by Fourier transform infrared spectroscopy, which revealed the breakage and formation of chemical bonds in the backbone of the polymer. This is an intriguing case study since fullerene 60, which is thought to be harmful, assisted in the consortia’s bacteria’s breakdown.47As the bacteria’s exponential phase lengthened by 36 hours, the addition of superparamagnetic iron oxide nanoparticles (SPION) to media containing the trio of Microbacterium sp., Pseudomonas putida and Bacterium Te68R produced favourable outcomes. 10.6 nm SPION was determined to be the appropriate size to improve the consortium’s biodegradation capacity. These experiments prove how bacteria-nanoparticles interaction is crucial in increasing the biodegradation efficiency and also in increasing the beneficial phases in the growth cycle of bacteria.48 From a hyper alkaline spring in Zambales, Philippines two bacterial strains were isolated. A consortium was made using these two bacteria. Further analysis displayed that they were associated with Bacillus pseudofirmus and Bacillus agaradhaerens. Iron oxide nanoparticles (IONPs) were introduced to the consortium, and this had a number of positive effects, including a shorter lag phase and a longer stationary phase. The weight of the leftover polymer was reduced after 60 days of polymer incubation in the media, demonstrating the beneficial effects of the interaction between bacteria and nanoparticles.

The protein content of the cells that adhered to the film was also found to be increased. Fourier transform infrared (FTIR) and scanning electron microscopy (SEM) portrayed the disruption in the surface texture of the polymers and the shifting of bonds in the polymer’s backbone.49 The size of the polymer in the medium directly influences the rate of its biodegradation in the medium. In this scenario, titania nanoparticles play a major role by photo-catalytically degrading LDPE to smaller fragments, so that the bacteria can consume them easily. In this case study, protein-coated titania nanoparticle (TNPs), which were produced by the Sol-gel method was used. An experiment was carried out for 21 days, which proved that Lactobacillus plantarum species along with the help of TNPs reduced the tensile strength of LDPE present in the medium by 21%. This was further confirmed when analysis reports confirmed the breaking and weakening of the bonds in the polymer backbone followed by carboxyl functional group formation.50 Another study by scientists concentrated on degrading plastics by the formation of biofilm on the surface of the polymers. The strain Stenotrophomonas pavanii (CC18) showed the highest rate of biofilm formation and the degradation of LDPE was affirmative when results portrayed the increase in Keto Carbonyl, Ester Carbonyl, and Vinyl Bond index compared to the control.51

These new methods open up newer methods to the persisting problem of plastic pollution. Older methods of plastic disposal were energy and consuming and produced hazardous compounds on plastic degradation, while nanotechnology provides a sustainable solution.

Replacement for Plastics

Whatever disadvantages or effects it may cause, no one can deny that plastic has become an integral part of literally everything. The reason it is a very popular choice is due to its versatility and to find a replacement to such a material is surely a herculean task. Even after a decade of research and various replacements suggested, nothing has come close to beating plastic in the mass scale. But that does not mean research in replacements for plastic is a dead end. Various techniques in nanotechnology have been synthesised to create materials incorporated with nanoparticles like milk protein, grape waste, PCL polyesters etc.52 Out of these, biopolymers are a tough contender to replace plastics as they combine versatility of biomolecules and the advantages nanoparticles bring to the table.

Biopolymers

Synthetic polymer disposal platforms have not been developed in a way that is environmentally friendly. As a result, their wastes frequently act as ongoing sources of contamination and the discharge of dangerous compounds. Biopolymers created from natural sources (plant, animal, or microbial) are thus acknowledged as an alluring and viable replacement for synthetic polymers in a number of ways. Biopolymers are actually any natural polymers created using the cells of living organisms. They are made of monomeric units that bond together covalently to form larger compounds. The type of biopolymer differs between polynucleotides, polysaccharides and polypeptides depending on the monomeric unit used to form the compound. Most biopolymers spontaneously fold into specific structures that decide their biological functions and depend on the primary structures.

Over the past ten years, there has been an exponential increase in the study of sequence-defined polymers and associated ultraprecise, monodisperse synthetic macromolecules. Early publications have mainly been researched or reviews focused on developing synthetic pathways for their preparation. With the help of these synthetic methods, it is now possible to envision a number of exciting applications and better understand the relationships between structure and property. As a result, application-focused publications based on discrete synthetic macromolecules have become more common over the past three years. As a result, a great deal of fascinating research has concentrated on material science applications like foldamers, macromolecular data storage and encryption, and discrete structure self-assembly. In the sphere of biological science, several research programs have also focused on these structures53.

Polymeric biomaterials are modified or synthetic polymers created for a variety of uses. A true bio-renewable method of synthesizing new biopolymers is to engineer their biosynthesis in plants. Like all other polymer businesses, these polymers are produced in bulk and then moulded for a specific purpose. Microorganisms produce a wide range of biopolymers, such as polysaccharides, polyesters, and polyamides, ranging from viscous solutions to plastics.

Microorganisms need a certain set of nutrients and a controlled environment in order to manufacture biopolymers. They can be produced chemically via the polymerization of monomers, which are also produced chemically through fermentation, or directly through direct fermentation. Most biopolymers are biocompatible and have no detrimental effects on biological systems. It is hypothesized that bacterial defense mechanisms or the demand for storage materials are responsible for the production of biopolymers. They can be broken down by enzymes, bacteria, and natural processes before being reabsorbed into the environment. A type of plastic made from renewable biomass sources, such as vegetable oil, maize starch, pea starch, and others, is known as a biopolymer or organic plastic. The preservation of fossil resources and the decrease of CO2 emissions can be done by placing more emphasis on biopolymers, which will support sustainable development54.

The main difference between biopolymers and synthetic polymers is that synthetic polymers tend to have more simplified and stochastic structures. This causes the molecular mass of the polymer to be diversified – an advantage biopolymer does not have. In fact, as their synthesis is controlled, all biopolymers of a type are all alike and contain similar sequences and a number of monomers causing mono dispersity. 55

Nanotechnology in Biopolymers

The development of biodegradable biopolymer-based packaging materials that have active ingredients such light blockers, plasticizers, crosslinkers, diffusion blockers, antimicrobials, antioxidants, and sensors is highly sought after since many of these compounds are volatile, chemically unstable, water-insoluble, matrix-incompatible, or have detrimental effects on film characteristics, it is difficult to directly incorporate them into the packaging materials. These challenges are typically overcome by encapsulating the active ingredients into food-grade nanoparticles, which are then included into the packaging materials. These nano-encapsulated active substances can significantly enhance the functional performance of biopolymer-based coatings or films56.

The main advantage that biopolymers hold over synthetic polymers is that the synthetic polymer disposal methods have not been developed in a way that is environmentally friendly. Whereas most biopolymers are naturally biodegradable57. Hence it is not surprising that nanotechnology has something to give towards the development of various different types of biopolymers with various applications.

The protein fish gelatin (FG), which is biodegradable, processable, and has a reserve that can be replenished, has enormous potential for bio-packaging. The inadequate water barrier, poor moisture stability, and low mechanical strength of FG have raised questions about its suitability for use as packing material. The most recent developments in FG-based film development will be discussed in this study, and it will be made clear how important these films are for modifying the characteristics of such films. The numerous nanofillers that have been used into FG to produce bio-nanocomposite films include metal ions (silver, copper), metal oxide nanoparticles, nano clays (montmorillonite, sepiolite), and polysaccharide nanofillers (nano whiskers/nanofibers) (ZnO, TiO2) 58 Biopolymers also play a significant role in biomedical applications such as drug delivery systems, tissue engineering, dialysis membrane, implants, wound treatment, and biosensors that have the scope to improve human health due to their significant biocompatibility and biodegradability. Biopolymers are materials created from renewable resources that are utilized in packaging and as food additives in the food industry. Animal-derived chitosan and chitin are employed in biological applications. They are renewable, biodegradable, and not particularly poisonous. Additionally, there are numerous uses for animal-derived biopolymers in the healthcare and food industries59.

Biopolymers have also gained recognition as a potential class of materials with numerous uses, chief among them being medicine. These materials are great choices for use in implantable devices because they have properties including biocompatibility, biodegradation, and non-cytotoxicity. Biopolymers work well with the body of a human. The main traits of biopolymers are being investigated, along with the potential of additional biopolymers, such as polylactic acid (PLA), silk, and chitosan, for application in implanted medical devices.

Orthopedic applications have made use of implants composed of PLA-PGA (polyglycolic acid) copolymers. Plaques or screws made of compression-moulded copolymers have been used to repair fractures and fill in bony deformities. The materials have also been used as scaffolding to facilitate the body’s natural production of new cartilage. Copolymers of PLA and PGA are more valuable than homopolymers of PLA and PGA due to their biocompatibility and nontoxicity as well as the ability to modify their rate of breakdown for various applications60.

Various compounds found in the natural realm are also being considered to be used as biopolymers. It is evident that starch is important to both plants and people. Humans require it for numerous commercial items in addition to being an essential component of their nutrition, whereas plants view it as a source of energy. The potential uses of starch and its derivatives in the production of paper, textiles, and adhesives have already been studied. Due to their biodegradable and renewable qualities, they can take the role of synthetic chemicals in a variety of other products, including plastics, detergents, pharmaceutical tablets, pesticides, cosmetics, and even oil-drilling fluids.

Recently, cellulose-based nanofibrils have seen a lot of use. CNF or nanocellulose are frequently created when the lignin component of cellulose is eliminated through mechanical grinding or high-pressure fluidization. The fibrils that makeup CNF are quite long (several m), thin (5–20 nm), and have a high aspect ratio. It can be used to manufacture biodegradable, environmentally safe, homogeneous, and dense films for a range of functions, particularly in the biomedical industry, because it produces a transparent gel-like substance at low concentrations. There have been reports of CNF extraction from pulps of various materials, including coir, banana, sugar beet, hemp, softwood, and hardwood. The cellulose’s varied thermal, mechanical, barrier, and physical properties can be enhanced by the addition of various plasticizers, enabling it to be employed in a variety of commercial applications61.

In 2007, silk fibres were transformed into carbon fibres with the use of iodine, and the carbon yield, fibre shape, structure, and mechanical properties were studied. A single or multi-step carbonization technique was used in the preparation. Silk fibroin (SF) fibres were heated from 25 to 800 °C in a single step at a rate of 5 °C min-1 in an argon atmosphere. The resulting carbon fibre, however, was too fragile and partially melted to handle. The optimal thermal breakdown rate of silk was used to develop a multi-step carbonization process that heated untreated and iodinated SF fibres from 25 to 800 °C. This was done to enhance efficiency. This multi-step process produced a carbon yield of about 36 weight percent, which is much higher than the yield for untreated SF. Iodinated SF was used to create carbon fibres that were both structurally sound and stable in appearance. X-ray diffraction, Raman spectroscopy, and transmission electron microscopy analysis revealed that the produced carbon fibres from both untreated and iodinated SFs had a mostly amorphous structure. The strength of carbon fibres produced from iodinated SF using the multi-step carbonization process was much higher than that of untreated SF. According to viscoelastic tests, heating the iodine to 280 °C caused the SF to intermolecularly cross-link and its melt flow to be inhibited, increasing the yield and improving the performance of the carbon fibre62.

Conclusion

Plastics have been around for more than five decades, but their problems started to loom over mankind only after overproduction and uncontrolled usage. Several problem-solving mechanisms have been introduced in the field of plastic degradation, but many of them failed to provide a sustainable and large-scale implementation pattern. Nanotechnology opens up many prospects in the field of plastic degradation, providing the world modern and efficient solution to mankind’s biggest problem of polymer degradation. Plastic accumulation has always been a problem for mankind as plastics get accumulated or deposited in large amounts in the oceans and other water bodies, posing a severe threat to several aquatic life forms. Plastics, when buried or piled up in land, create another problem by retaining the water and therefore inhibiting the groundwater recharge during the monsoon period. Many animals get affected by plastics as they mistake them for food and swallow them, only to end up with a permanent polymer in their digestive system. In the end, the polymer choaks the organism to death or retards the organism in every possible way by blocking the system. The photocatalytic degradation properties of various nanoparticles were studied and their potential to degrade LDPE is extraordinary. Methods like solar irradiation were modified with the addition of nanoparticles to the polymer matrices, which enhanced the degrading efficiency of the nanoparticles. Nanoparticles offered an Energy-efficient and large-scale implementable methods to tackle the world’s plastic accumulation problem. When nanoparticles produced from various plant sources were tested to degrade polymers, the results obtained were positive and encouraging. This ensured a renewable resource for nanomaterials with a degrading capacity, to tackle large scale problems. The by-products of these reactions were also environment-friendly, as the nanomaterials can be recovered for the next cycle of degradation. Another interesting area of science opened up when the nanoparticles were combined with polymer-biodegrading microorganisms (especially bacteria). The microorganisms with polymer-degrading capabilities were isolated from pits filled with non-biodegradable plastics. The results obtained were exemplary as their interaction was found to be beneficial. The nanoparticles either increased the log phase or stationary phase of the bacteria or decreased the lag phase in their growth cycles. This was very beneficial to the microorganisms as their abilities were heightened and their lifespan increased. The introduction of LDPE (low-density polyethylene) films into Nanoparticles-infused bacterial consortia, and the degradation of the LDPE films was inevitable. We as a species have reached a point of no return where we would not take anything less than plastics to satisfy all our needs and hence the replacements suggested for plastics has to be on par or perform better than plastics. It suffices to say that it is a herculean task that researchers across the globe have taken up. Biopolymers and nanomaterials are for sure top contenders in the race to replace plastics and we are sure that there will be innovative solutions proposed in the future, a revolutionary idea on par with the discovery of fire, electricity and plastics.

Conflict of Interest

There is no conflict of interest.

Funding Sources

There are no funding sources.

References

- Adebiyi-Abiola, B. B., Assefa, S., Sheikh, K., & García, J. M. (2019). Cleaning up plastic pollution in Africa. Science, 365(6459), 1249–1251. https://doi.org/10.1126/SCIENCE.AAX3539

CrossRef - Alabi, O. A., Ologbonjaye, K., Awosolu, O., Alabi, O. A., Ologbonjaye, K. I., & Alalade, O. E. (2019). Public and environmental health effects of plastic wastes disposal: a review. Researchgate.Net, 5, 21. https://doi.org/10.23937/2572-4061.1510021

CrossRef - Applications of Nanotechnology | National Nanotechnology Initiative. (n.d.). Retrieved July 28, 2022, from https://www.nano.gov/about-nanotechnology/applications-nanotechnology

- Applications of Nanotechnology | National Nanotechnology Initiative. (n.d.). Retrieved July 28, 2022, from https://www.nano.gov/about-nanotechnology/applications-nanotechnology

- Baig, N., Kammakakam, I., Advances, W. F.-M., & 2021, undefined. (n.d.). Nanomaterials: A review of synthesis methods, properties, recent progress, and challenges. Pubs.Rsc.Org. Retrieved July 28, 2022, from https://pubs.rsc.org/en/content/articlehtml/2021/ma/d0ma00807a

- Barnes, D. K. A., Galgani, F., Thompson, R. C., & Barlaz, M. (2009). Accumulation and fragmentation of plastic debris in global environments. Philosophical Transactions of the Royal Society B: Biological Sciences, 364(1526), 1985–1998. https://doi.org/10.1098/RSTB.2008.0205

CrossRef - Bhatia, M., Girdhar, A., Nanotechol, B. C.-J. N., & 2013, undefined. (n.d.). Implicating nanoparticles as potential biodegradation enhancers: a review. Academia.Edu. Retrieved July 24, 2022, from https://www.academia.edu/download/74514075/Implicating_Nanoparticles_as_Potential_B20211110-29269-nh95wg.pdf

- Borrelle, S., Ringma, J., Law, K., Science, C. M.-, & 2020, undefined. (2020). Predicted growth in plastic waste exceeds efforts to mitigate plastic pollution. Science.Org, 369(6509), 1515–1518. https://doi.org/10.1126/science.aba3656

CrossRef - Brock, S. L. (2004). Nanostructures and Nanomaterials: Synthesis, Properties and Applications By Guozhang Cao (University of Washington). Imperial College Press (distributed by World Scientific): London. 2004. xiv + 434 pp. $78.00. ISBN 1-86094-415-9. Journal of the American Chemical Society, 126(44), 14679–14679. https://doi.org/10.1021/JA0409457

CrossRef - Consumption, F. de S.-C. and R., & 2021, undefined. (n.d.). The role of plastic concerning the sustainable development goals: The literature point of view. Elsevier. Retrieved July 28, 2022, from https://www.sciencedirect.com/science/article/pii/S2666784321000140

- Dave, D., Chauhan, K., Khimani, A., Soni, K., & Vaidya, Y. (2021). Photocatalytic degradation of low-density polythene using protein-coated titania nanoparticles and Lactobacillus plantarum . Environmental Technology, 1–12. https://doi.org/10.1080/09593330.2021.1980828

CrossRef - David, M., Prakash, L., Sangeetha, J., … J. N.-… of nanomaterials and, & 2021, undefined. (n.d.). Degradation of plastics using nanomaterials. Springer. Retrieved July 28, 2022, from https://link.springer.com/content/pdf/10.1007/978-3-030-36268-3_74.pdf

CrossRef - Eriksen, M., Lebreton, L. C. M., Carson, H. S., Thiel, M., Moore, C. J., Borerro, J. C., Galgani, F., Ryan, P. G., & Reisser, J. (2014). Plastic Pollution in the World’s Oceans: More than 5 Trillion Plastic Pieces Weighing over 250,000 Tons Afloat at Sea. PLoS ONE, 9(12). https://doi.org/10.1371/JOURNAL.PONE.0111913

CrossRef - Goh, P., Kang, H., Ismail, A., Khor, W., Chemosphere, L. Q.-, & 2022, undefined. (n.d.). Nanomaterials for microplastic remediation from aquatic environment: Why nano matters? Elsevier. Retrieved July 28, 2022, from https://www.sciencedirect.com/science/article/pii/S0045653522009110

CrossRef - Halada, G., Materials, A. O.-H. of E. D. of, & 2018, undefined. (n.d.). Environmental degradation of engineered nanomaterials: Impact on materials design and use. Elsevier. Retrieved July 28, 2022, from https://www.sciencedirect.com/science/article/pii/B9780323524728000113

- Health, M. S.-C. O. in E. S. &, & 2021, undefined. (n.d.). Nanomaterials: types, properties, synthesis, emerging materials, and toxicity concerns. Elsevier. Retrieved July 28, 2022, from https://www.sciencedirect.com/science/article/pii/S246858442100091X

- Jayaprakash, V., & Palempalli, U. M. D. (2019). Studying the effect of biosilver nanoparticles on polyethylene degradation. Applied Nanoscience (Switzerland), 9(4), 491–504. https://doi.org/10.1007/S13204-018-0922-6

CrossRef - Joy Cada, E. G., Lei Muyot, M. C., Maria Sison, J. C., & Baculi, R. Q. (2019). Enhanced in vitro biodegradation of low-density polyethylene using alkaliphilic bacterial consortium supplemented with iron oxide nanoparticles. Philippine Science Letters, 12.

- Kamalian, P., Khorasani, S. N., Abdolmaleki, A., Karevan, M., Khalili, S., Shirani, M., & Neisiany, R. E. (2020). Toward the development of polyethylene photocatalytic degradation. Journal of Polymer Engineering, 40(2), 181–191. https://doi.org/10.1515/POLYENG-2019-0230/PDF

CrossRef - Kapri, A., Zaidi, M., and, R. G.-J. of microbiology, & 2010, undefined. (n.d.). Implications of SPION and NBT nanoparticles upon In Vitro and In Situ biodegradation of LDPE film. Koreascience.or.Kr. Retrieved July 26, 2022, from https://www.koreascience.or.kr/article/JAKO201018860405114.page

- Khan, F. A. (2020). Synthesis of nanomaterials: Methods & technology. Applications of Nanomaterials in Human Health, 15–21. https://doi.org/10.1007/978-981-15-4802-4_2

CrossRef - Lamb, J. B., Willis, B. L., Fiorenza, E. A., Couch, C. S., Howard, R., Rader, D. N., True, J. D., Kelly, L. A., Ahmad, A., Jompa, J., & Harvell, C. D. (2018). Plastic waste associated with disease on coral reefs. Science, 359(6374), 460–462. https://doi.org/10.1126/SCIENCE.AAR3320

CrossRef - MacArthur, D. E. (2017). Beyond plastic waste. Science, 358(6365), 843. https://doi.org/10.1126/SCIENCE.AAO6749

CrossRef - MacLeod, M., Arp, H. P. H., Tekman, M. B., & Jahnke, A. (2021). The global threat from plastic pollution. Science, 373(6550), 61–65. https://doi.org/10.1126/SCIENCE.ABG5433

CrossRef - Majhi, K., and, M. Y.-G. S. P. for C., & 2021, undefined. (n.d.). Synthesis of inorganic nanomaterials using carbohydrates. Elsevier. Retrieved July 28, 2022, from https://www.sciencedirect.com/ science/article/pii/B9780128218877000033

- Martin, C., Baalkhuyur, F., Valluzzi, L., Saderne, V., Cusack, M., Almahasheer, H., Krishnakumar, P. K., Rabaoui, L., Qurban, M. A., Arias-Ortiz, A., Masqué, P., & Duarte, C. M. (2020). Exponential increase of plastic burial in mangrove sediments as a major plastic sink. Science Advances, 6(44). https://doi.org/10.1126/SCIADV.AAZ5593

CrossRef - Mehmood, C., Qazi, I., Hashmi, I., … S. B.-I., & 2016, undefined. (n.d.). Biodegradation of low density polyethylene (LDPE) modified with dye sensitized titania and starch blend using Stenotrophomonas pavanii. Elsevier. Retrieved July 27, 2022, from https://www.sciencedirect.com/ science/article/pii/ S0964830516300257

CrossRef - Meijer, L. J. J., van Emmerik, T., van der Ent, R., Schmidt, C., & Lebreton, L. (2021). More than 1000 rivers account for 80% of global riverine plastic emissions into the ocean. Science Advances, 7(18). https://doi.org/10.1126/SCIADV.AAZ5803 Module-1_Unit-5: Application of Nanoparticles. (n.d.).

CrossRef - Module-1_Unit-5: Application of Nanoparticles. (n.d.).

- North, E. J., & Halden, R. U. (2013). Plastics and environmental health: The road ahead. Reviews on Environmental Health, 28(1), 1–8. https://doi.org/10.1515/REVEH-2012-0030/HTML

CrossRef - Obebe, S., Technol, A. A.-I. J. E. A. S., & 2020, undefined. (2020). Plastic pollution: causes, effects and preventions. Ijeast.Com, 4. http://ijeast.com/papers/85-95,Tesma412,IJEAST.pdf

CrossRef - Olajire, A. A., & Mohammed, A. A. (2019). Green synthesis of palladium nanoparticles using Ananas comosus leaf extract for solid-phase photocatalytic degradation of low density polyethylene film. Journal of Environmental Chemical Engineering, 7(4), 103270. https://doi.org/10.1016/ J.JECE.2019.103270

CrossRef - Pathak, V. M., & Navneet Kumar. (2017). Implications of SiO 2 nanoparticles for in vitro biodegradation of low-density polyethylene with potential isolates of Bacillus, Pseudomonas, and their synergistic effect on Vigna mungo growth. Energy, Ecology and Environment, 2(6), 418–427. https://doi.org/10.1007/s40974-017-0068-5

CrossRef - Plastic Waste and Pollution [Everything You Need To Know In 2020]. (n.d.). Retrieved July 28, 2022, from https://cleanstreets.westminster.gov.uk/plastic-waste-complete-guide/#1

- Pol, V. G., & Thiyagarajan, P. (2010). Remediating plastic waste into carbon nanotubes. Journal of Environmental Monitoring, 12(2), 455–459. https://doi.org/10.1039/B914648B

CrossRef - Raghavendra, V. B., Shankar, S., Govindappa, M., Pugazhendhi, A., Sharma, M., & Nayaka, S. C. (2021). Green Synthesis of Zinc Oxide Nanoparticles (ZnO NPs) for Effective Degradation of Dye, Polyethylene and Antibacterial Performance in Waste Water Treatment. Journal of Inorganic and Organometallic Polymers and Materials 2021 32:2, 32(2), 614–630. https://doi.org/10.1007/S10904-021-02142-7

CrossRef - Remya, R., Julius, A., Suman, T., … V. M.-J. of, & 2022, undefined. (n.d.). Role of Nanoparticles in Biodegradation and Their Importance in Environmental and Biomedical Applications. Hindawi.Com. Retrieved July 24, 2022, from https://www.hindawi.com/journals/jnm/2022/6090846/

CrossRef - Rochman, C., Browne, M., Halpern, B., Nature, B. H.-, & 2013, undefined. (n.d.). Classify plastic waste as hazardous. Nature.Com. Retrieved July 28, 2022, from https://www.nature.com/articles/494169a

- Rodrigues, M., Abrantes, N., … F. G.-E., & 2019, undefined. (n.d.). Impacts of plastic products used in daily life on the environment and human health: What is known? Elsevier. Retrieved July 28, 2022, from https://www.sciencedirect.com/science/article/pii/S1382668919300079

- Sah, A., Kapri, A., Zaidi, M. G. H., Negi, H., & Goel, R. (2010). Implications of Fullerene-60 upon in-vitro LDPE Biodegradation. J. Microbiol. Biotechnol, 20(5), 908–916. https://doi.org/ 10.4014 /jmb.0910.10025

CrossRef - Science, S. O., & Weckhuysen, B. M. (2020). Creating value from plastic waste. Science.Org, 370(6515), 6515. https://doi.org/10.1126/science.abe3873

CrossRef - Science, T. A.-, & 2020, undefined. (n.d.). Accumulation of plastic waste during COVID-19. Science.Org. Retrieved July 28, 2022, from https://www.science.org/doi/ full/10.1126/ science.abd9925

- Simon, N., Raubenheimer, K., Urho, N., Unger, S., Azoulay, D., Farrelly, T., Sousa, J., van Asselt, H., Carlini, G., Sekomo, C., Schulte, M. L., Busch, P. O., Wienrich, N., & Weiand, L. (2021). A binding global agreement to address the life cy cle of plastics. Science, 373(6550), 43–47. https://doi.org/10.1126/SCIENCE.ABI9010

CrossRef - Stubbins, A., Law, K. L., Muñoz, S. E., Bianchi, T. S., & Zhu, L. (2021). Plastics in the Earth system. Science, 373(6550), 51–55. https://doi.org/10.1126/SCIENCE.ABB0354

CrossRef - Thompson, R. C., Swan, S. H., Moore, C. J., & Vom Saal, F. S. (2009). Our plastic age. Philosophical Transactions of the Royal Society B: Biological Sciences, 364(1526), 1973–1976. https://doi.org/10.1098/RSTB.2009.0054

CrossRef - Weiss, L., Ludwig, W., Heussner, S., Canals, M., Ghiglione, J. F., Estournel, C., Constant, M., & Kerhervé, P. (2021). The missing ocean plastic sink: Gone with the rivers. Science, 373(6550), 107–111. https://doi.org/10.1126/SCIENCE.ABE0290

CrossRef - Zaidi, M. G. H., & Goel, R. (2009). Nanobarium Titanate As Supplement To Accelerate Plastic Waste Biodegradation By Indigenous Bacterial Consortia Metal oxide-GO View project. https://doi.org/10.1063/1.3183475

CrossRef - Zaidi, M. G. H., & Goel, R. (2009). Nanobarium Titanate As Supplement To Accelerate Plastic Waste Biodegradation By Indigenous Bacterial Consortia Metal oxide-GO View project. https://doi.org/10.1063/1.3183475

CrossRef - Zaidi, M. G. H., Satlewal, A., Goel, R., & Kapri, A. (2010). SPION-accelerated biodegradation of low-density polyethylene by indigenous microbial consortium Rhizobacteria-PGPR View project Waste Management View project Author’s personal copy SPION-accelerated biodegradation of low-density polyethylene by indigenous microbial consortium. https://doi.org/10.1016/j.ibiod.2010.02.002

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.