How to Cite | Publication History | PlumX Article Matrix

The Recent Developments in Dairy Technology

T. Eswar Ganesh Babu and S. A Mastan

Post Graduate Department of Biotechnology, DNR College, P.G Courses and Research Centre, Bhimvaram - 534202 India.

ABSTRACT: The global market for the production of microbial enzymes and use in dairy-products manufacture is considerably large, but is being dominated only by a limited number of enzyme producers. In India the microbial dairy enzymes requirement has been very limited till now. Presently, many of these microbial enzymes, such as microbial rennets and other enzymes, are being imported. Hence, there is a scope for the production of enzymes such as microbial rennet, lactase, proteinases, and lipases indigenously. In the near future, the requirement for these enzymes is bound to increase by leaps and bounds, basically due to requirement of value-added dairy products in the country.

KEYWORDS: Microbial enzymes; microbial rennets; lipases; lactase; proteinases; Dairy technology

Download this article as:| Copy the following to cite this article: Shukla. S. K, Ahmed. S. U, Tiwari. A, Mathew. J, Sharma. D. Molecular Cloning of Major Histocompatibility Complex Class I Cdna From Red Jungle Fowl (Gallus Gallus). Biosci Biotechnol Res Asia 2009;6(2) |

| Copy the following to cite this URL: Shukla. S. K, Ahmed. S. U, Tiwari. A, Mathew. J, Sharma. D. Molecular Cloning of Major Histocompatibility Complex Class I Cdna From Red Jungle Fowl (Gallus Gallus). Biosci Biotechnol Res Asia 2009;6(2). Available from: https://www.biotech-asia.org/?p=8731. |

Introduction

Indians are known to be lovers of milk and its products. As a sequel to white revolution, India has surged ahead to become the largest milk producer in the world, the production figure touched to 74 million tons for the year 1998. With growing urbanization, demand for processed dairy foods has increased considerably, in particular demand for different cheese varieties, and low-lactose milk due to increasing intolerance of human beings to lactose in milk and other milk products. For improving the quality of milk and milk products, a number of different enzymes from microbial as well as from nonmicrobial sources have potential applications in dairy processing.

The use of rennet in cheese manufacture was among the earliest applications of exogenous enzymes in food processing, dating back to approximately 6000 B C. In 1994, the total production of cheese was 8000 metric tons against a total demand of 9000 metric tons. The projected demand by 2000 A D is around 30,000 metric tons. The use of rennet, as an exogenous enzyme, in cheese manufacture is perhaps the largest single application of enzymes in food processing. In recent years, proteinases have found additional applications in dairy technology, for example in acceleration of cheese ripening, modification of functional properties and preparation of dietic products1. Principal among some enzymes that have important and growing applications are lipases and b -galactosidases. Enzymes with limited applications include glucose oxidase, superoxide dismutase, sulphydryl oxidase, etc. The increasing use of enzymes to produce specific products with characteristic attributes can be emphasized by the world-wide sale of industrial enzymes approximating to US $ 1.6 billion, which is expected to reach US $ 3.0 billion by the year 2008. Almost 45% of this is shared by the food industry and the remaining is shared by detergent (34.4%), textile (11%), leather (2.8%), pulp and paper (1.2%) industries and other industries (5.6%) excluding enzymes for use in diagnostics and therapeutics (2).

India being the highest producer of milk in the world, and consequently the surplus availability of milk in our country has triggered the food and dairy industry to convert the liquid milk into value-added products using biochemical and enzymatic processes.

Microbial rennets in dairy applications

Milk contains proteins, specifically caseins, that maintain its liquid form. Proteases are enzymes that are added to milk during cheese production, to hydrolyze caseins, specifically kappa casein, which stabilizes micelle formation preventing coagulation. Rennet and rennin are general terms for any enzyme used to coagulate milk. Technically rennet is also the term for the lining of a calf’s fourth stomach. The most common enzyme isolated from rennet is chymosin. Chymosin can also be obtained from several other sources, but indigenous microbial chymosin (from fungi or bacteria) is ineffective for making cheddar and other hard cheeses. Limited supplies of calf rennet have prompted genetic engineering of microbial chymosin by cloning calf prochymosin genes into bacteria. Bioengineered chymosin may be involved in production of up to 70% of cheese products. While use of bioengineered enzymes spares the lives of calves, it presents ethics issues for those opposed to eating foods prepared with GEMs.

Animal rennet (bovine chymosin) is conventionally used as a milk-clotting agent in dairy industry for the manufacture of quality cheeses with good flavour and texture. Owing to an increase in demand for cheese production world wide – i.e. 4% per annum over the past 20 years, approximating 13.533 million tons (3) – coupled with reduced supply of calf rennet, has therefore led to a search for rennet substitutes, such as microbial rennets. At present, microbial rennet is used for one-third of all the cheese produced companies in world wide.

Rennin acts on the milk protein in two stages, by enzymatic and by nonenzymatic action, resulting in coagulation of milk. In the enzymatic phase, the resultant milk becomes a gel due to the influence of calcium ions and the temperature used in the process4. Many microorganisms are known to produce rennet-like proteinases which can substitute the calf rennet. Microorganisms like Rhizomucor pusillus, R. miehei, Endothia parasitica, Aspergillus oryzae, and Irpex lactis are used extensively for rennet production in cheese manufacture. Extensive research that has been carried out so far on rennet substitutes has been reviewed by several authors (5–7). Different strains of species of Mucor are often used for the production of microbial rennets. Whereas best yields of the milk-clotting protease from Rhizomucor pusillus are obtained from semisolid cultures containing 50% wheat bran, R. miehei and Endothia parasitica are well suited for submerged cultivation. Using the former, good yields of milk-clotting protease may be obtained in a medium containing 4% potato starch, 3% soybean meal, and 10% barley. During growth, lipase is secreted together with the protease. Therefore, the lipase activity has to be destroyed by reducing the pH, before the preparation can be used as cheese rennet.

Microbial rennets from various microorganisms (marketed under the trade names such as Rennilase, Fromase, Marzyme, Hanilase, etc.) being marketed since the 1970s have proved satisfactory for the production of different kinds of cheese. The molecular and enzymatic properties of chymosins have been studied extensively (6). Although the proteolytic specificities of the three commonly used fungal rennets are considerably different from those of calf chymosin, these rennets have been used to produce acceptable cheeses. Recently Novo Nordisk has succeeded in expressing just one proteolytic enzyme from the fungus R. miehei in the well-known organism A. oryzae. This host organism is able to produce the single protease that cleaves the -casein into a glycomacropeptide and para -casein by hydrolysing only at the phe105–met106 peptide bond between phenyl alanine and methionine. This monocomponent enzyme product has the trade name Novoren8. One major drawback of microbial rennet use in cheese manufacture, is the development of off flavour and bitter taste in the nonripened as well as in the ripened cheeses. The rennets from microbial sources are more proteolytic in nature in comparison to rennet from animal sources, resulting in production of some bitter peptides during the process of cheese ripening (9). Hence, attempts have been made to clone the gene for calf chymosin, and to express it in selected bacteria, yeasts, and molds.

Recombinant rennets for cheese manufacture

Due to shortage of calf stomachs and the economic value of cheese rennet, gene for calf chymosin was one of the first genes for mammalian enzymes that was cloned and expressed in microorganisms (10). Many different laboratories have cloned the gene for calf prochymosin in Escherichia coli, and analysed the structure of the gene as well as the properties of the recombinant chymosin (11). The expressed proenzyme in E. coli is present mainly as insoluble inclusion bodies, comprised of reduced prochymosin as well as molecules that are interlinked by disulphide bridges. After disintegration of the cells, inclusion bodies are harvested by centrifugation. The individual laboratories have reported some differences in the procedure for renaturation of prochymosin from the inclusion bodies, but all have followed the same general scheme. The enzymatic properties of recombinant E. coli chymosin are indistinguishable from those of native calf chymosin (12). The enzymes were identical when observed by immunodiffusion in gels, but a slight difference was observed by enzyme linked immunosorbent assay (13) (ELISA).

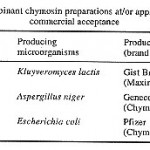

|

Table 1

|

The gene for prochymosin has also been cloned in Saccharomyces cerevisiae; the levels of expression have been reported to be 0.5 to 2.0% of total yeast protein14,15. In yeast, about 20% of the prochymosin can be released in soluble form which can be activated directly; the remaining 80% is still associated with the cell debris. The cloning of chymosin was carried out without the prosequence14. Though the level of chymosin mRNA was similar to that of prochymosin mRNA, no milk-clotting activity was observed in clones containing the chymosin gene only. The results suggest that the prosequence is essential for correct folding of the polypeptide chain. The zymogen for the aspartic proteases from R. pusillus, also called mucor rennin, has likewise been cloned and expressed in yeast16. Studies on its conversion to active form showed that secretion of R. pusillus protease from recombinant yeast was dependent on glycosylation of the enzyme (16).

Compared to yeast, the filamentous fungi generally secrete larger quantities of proteins into the culture medium. Furthermore, filamentous fungi secrete the heterologous proteins with correct folding of the polypeptide chain, and process correct pairing of sulphydryl groups. The gene for R. miehei protease has been expressed in A. oryzae. Prochymosin has been expressed in Kluyveromyces lactis, A. nidulans, A. niger, and Trichoderma reesei. In most of the cases, the reported yields of the model systems were about 10–40 mg of enzyme per litre of culture medium. However, 3.3 g of enzyme per liter has also been achieved (17). Yeast, Kluyveromyces lactis, has recently been used as an efficient host for the secretion of recombinant chymosin, which has led to the development of large-scale production process for chymosin (18). If produced on an industrial scale, the yields will perhaps be of the latter magnitude. Chymosins which are approaching or have marketing and legal acceptance, and generally regarded as safe (GRAS) are listed in Table 1 (19). Most of the companies produce recombinant rennet of cattle calf origin in different microbial hosts, however in India, the major source of milk is buffalo, showing a different composition from that of cow. The rennet from buffalo source has inherent compatibility for clotting buffalo milk. Therefore, National Dairy Research Institute, Karnal, has taken a lead in cloning gene of buffalo chymosin. The buffalo chymosin cDNA has been cloned in E. coli and partial N-terminal sequencing of the purified buffalo chymosin indicates that it is highly homologous to the cattle chymosin (20).

Several cheese making experiments have been carried out with recombinant chymosin and the general aspects of recombinant chymosin have been dealt with in a report19. Since most of the rennet (> 90 %) added to cheese milk is lost in the whey, immobilization would considerably extend its catalytic life. Several rennets have been immobilized, but their efficiency as milk coagulants has been questioned. So, there is a fairly general support for the view that immobilized enzymes cannot coagulate milk properly owing to inaccessability of the Phe–Met peptide bond of k-casein, and that the apparent coagulating activity of immobilized rennets is due to leaching of the enzyme from the support (21).

Different types of conventional cheeses have been successfully made by using recombinant rennet on an experimental or pilot scale. No major differences have been detected between cheeses made with recombinant chymosins or natural enzymes, regarding cheese yield, texture, smell, taste and ripening. The recombinant chymosins are identical with calf rennet according to the report on biochemical and genetic evidences (19).

Lactase in dairy industry

Lactose, the sugar found in milk and whey, and its corresponding hydrolase, lactase or b -galactosidase, have been extensively researched during the past decade (22). This is because of the enzyme immobilization technique which has given new and interesting possibilities for the utilization of this sugar. Because of intestinal enzyme insufficiency, some individuals, and even a population, show lactose intolerance and difficulty in consuming milk and dairy products. Hence, low-lactose or lactose-free food aid programme is essential for lactose-intolerant people to prevent severe tissue dehydration, diarrhoea, and, at times, even death. Another advantage of lactase-treated milk is the increased sweetness of the resultant milk, thereby avoiding the requirement for addition of sugars in the manufacture of flavoured milk drinks. Manufacturers of ice cream, yoghurt and frozen desserts use lactase to improve scoop and creaminess, sweetness, and digestibility, and to reduce sandiness due to crystallization of lactose in concentrated preparations. Cheese manufactured from hydrolysed milk ripens more quickly than the cheese manufactured from normal milk.

Technologically, lactose crystallizes easily which sets limits to certain processes in the dairy industry, and the use of lactase to overcome this problem has not reached its fullest potential because of the associated high costs. Moreover, the main problem associated with discharging large quantities of cheese whey is that it pollutes the environment. But, the discharged whey could be exploited as an alternate cheap source of lactose for the production of lactic acid by fermentation. The whey permeate, which is a by-product in the manufacture of whey protein concentrates, by ultrafiltration could be fermented efficiently by Lactobacillus bulgaricus (22).

Lactose can be obtained from various sources like plants, animal organs, bacteria, yeasts (intracellular enzyme), or molds. Some of these sources are used for commercial enzyme preparations. Lactase preparations from A. niger, A. oryzae, and Kluyveromyces lactis are considered safe because these sources already have a history of safe use and have been subjected to numerous safety tests. The most investigated E. coli lactase is not used in food processing because of its cost and toxicity problems.

Properties of lactase

Lactase is a glycoside hydrolase enzyme that cuts lactose into it’s constituent sugars, galactose and glucose. Without sufficient production of lactase enzyme in the small intestine, humans become lactose intolerant, resulting in discomfort (cramps, gas and diarrhea) in the digestive tract upon ingestion of milk products. Lactase is used commercially to prepare lactose-free products, particularly milk, for such individuals. It is also used in preparation of ice cream, to make a creamier and sweeter-tasting product. Lactase is usually prepared from Kluyveromyces sp. of yeast and Aspergillus sp. of fungi.

The properties of the enzyme depend on its source. Temperature and pH optima differ from source to source and with the type of particular commercial preparation. Immobilization of the enzymes, method of immobilization, and type of carrier can also influence these optima values. In general, fungal lactase have pH optima in the acidic range 2.5–4.5, and yeast and bacterial lactases in the neutral region 6–7 and 6.5–7.5, respectively. The variation in pH optima of lactases makes them suitable for specific applications, for example fungal lactases are used for acid whey hydrolysis, while yeast and bacterial lactases are suitable for milk (pH 6.6) and sweet whey (pH 6.1) hydrolysis. Product inhibition, e.g. inhibition by galactose, is another property which also depends on the source of lactase. The enzyme from A. niger is more strongly inhibited by galactose than that from A. oryzae. This inhibition can be overcome by hydrolysing lactose at low concentrations by using immobilized enzyme systems or by recovering the enzyme using ultrafiltration after batch hydrolysis. Lactase from Bacillus species are superior with respect to thermostability, pH operation range, product inhibition, and sensitivity against high-substrate concentration. Thermostable enzymes, able to retain their activity at 60°C or above for prolonged periods, have two distinct advantages viz. they give higher conversion rate or shorter residence time for a given conversion rate, and the process is less prone to microbial contamination due to higher operating temperature. Bacillus species have a pH optima of 6.8 and a temperature optima of 65°C. Its high activity for skim milk, and less inhibition by galactose has made it suitable for use as a production organism for lactase (23).

The enzymatic hydrolysis of lactose can be achieved either by free enzymes, usually in batch fermentation process, or by immobilized enzymes or even by immobilized whole cells producing intracellular enzyme. Although numerous hydrolysis systems have been investigated, only few of them have been scaled up with success and even fewer have been applied at an industrial or semi-industrial level. Several acid hydrolysis systems have been developed to industry-scale level. Large-scale systems which use free enzyme process have been developed for processing of UHT-milk and processing of whey, using K. lactis lactase (Maxilact, Lactozyme). Several commercial immobilized systems have been developed for commercial exploitation. Snamprogretti process of industrial-scale milk processing technology in Italy is one such working systems. They make use of fibre-entrapped yeast lactase in a batch process, and the milk used is previously sterilized by UHT. For pilot plants, there are three other processes designed and developed to handle milk; (i) by Gist-Brocades, Rohm GmbH (Germany), and (ii) by Sumitomo, Japan. These are continuous processes with short residence times. Processing of whey UF-permeate is accomplished by the system developed by Corning Glass, Connecticut, Lehigh, Valio and Amerace corp. The process by Corning Glass is being applied at commercial scale in the bakers yeast production using hydrolysed whey (23).

Microbial enzymes in accelerated cheese ripening

Cheese ripening is a complex process mediated by biochemical and biophysical changes during which a bland curd is developed into a mature cheese with characteristic flavour, texture, and aroma. The desirable attributes are produced by the partial and gradual breakdown of carbohydrates, lipids, and proteins during ripening, mediated by several agents, viz. (i) residual coagulants, (ii) starter bacteria and their enzymes, (iii) nonstarter bacteria and their enzymes, (iv) indegenous milk enzymes, especially proteinases, and (v) secondary inocula with their enzymes.

Proteolysis occurs in all the cheese varieties and is a prerequisite for characteristic flavour development that can be regulated by proper use of the above agents. Cheese ripening is essentially an enzymatic process which can be accelerated by augmenting activity of the key enzymes. This has the advantage of initiating more specific action for flavour development compared to use of elevated temperatures that can result in accelerating undesirable nonspecific reactions, and consequently off flavour development. Enzymes may be added to develop specific flavours in cheeses, for example lipase addition for the development of Parmesan or Blue-type cheese flavours. Attempts to accelerate the multiple secondary flavour-forming-reactions, e.g. Strecker degradation, have been scarce. The pathways leading to the formation of flavour compounds are largely unknown, and therefore the use of exogenous enzymes to accelerate ripening is mostly an empirical process (24). Different microbial enzymes used to accelerate cheese ripening are presented in Table 2.

Studies on the hydrolysis of whole casein and isolated casein components to observe the kinetics and specificity of aspartic proteases in rennin, pepsin, and four microbial rennet substitutes indicated the considerable differences in the reaction velocity and the extent of hydrolysis on the rennet curd yield (25). The rennet enzymes were active even in the later phases of cheese-ripening.

Proteinases and peptidases

Proteolysis is characteristic of most cheese varieties and is indispensable for good flavour and textural development. Proteinases used in cheese processing include (i) plasmin, (ii) rennet, and (iii) proteinases (cell wall and/or intracellular) of the starter and nonstarter bacteria. Approximately 6% of the rennet added to cheese milk remains in the curd after manufacture and contributes significantly to proteolysis during ripening. Combinations of individual neutral proteinases and microbial peptidases intensified cheese flavour, and when used in combinations with microbial rennets reduced the intensity of bitterness caused by the latter. Acid proteases in isolation cause intense bitterness. Various animal or microbial lipases gave pronounced cheese flavour, low bitterness and strong rancidity, while lipases in combination with proteinases and/or peptidases give good cheese flavour with low levels of bitterness. In a more balanced approach to the acceleration of cheese ripening using mixtures of proteinases and peptidases, attenuated starter cells or cell-free extracts (CFE) are being favoured (24).

Catalase

The enzyme Catalase has found limited use in one particular area of cheese production. Hydrogen peroxide is a potent oxidizer and toxic to cells. It is used instead of pasteurization, when making certain cheeses such as Swiss, in order to preserve natural milk enzymes that are beneficial to the end product and flavour development of the cheese. These enzymes would be destroyed by the high heat of pasteurization. However, residues of hydrogen peroxide in the milk will inhibit the bacterial cultures that are required for the actual cheese production, so all traces of it must be removed. Catalase enzymes are typically obtained from bovine livers or microbial sources, and are added to convert the hydrogen peroxide to water and molecular oxygen.

Lipases

Lipases are used to break down milk fats and give characteristic flavours to cheeses. Stronger flavoured cheeses, for example, the italian cheese, Romano, are prepared using lipases. The flavour comes from the free fatty acids produced when milk fats are hydrolyzed. Animal lipases are obtained from kid, calf and lamb, while microbial lipase is derived by fermentation with the fungal species Mucor meihei. Although microbial lipases are available for cheese-making, they are less specific in what fats they hydrolyze, while the animal enzymes are more partial to short and medium-length fats. Hydrolysis of the shorter fats is preferred because it results in the desirable taste of many cheeses. Hydrolysis of the longer chain fatty acids can result in either soapiness, or no flavour at all.

Proteolytic enzymes of lactic acid bacteria in fermented milk products

The proteolytic system of lactic acid bacteria is essential for their growth in milk, and contributes significantly to flavour development in fermented milk products. The proteolytic system is composed of proteinases which initially cleaves the milk protein to peptides; peptidases which cleave the peptides to small peptides and amino acids; and transport system responsible for cellular uptake of small peptides and amino acids. Lactic acid bacteria have a complex proteolytic system capable of converting milk casein to the free amino acids and peptides necessary for their growth. These proteinases include extracellular proteinases, endopeptidases, aminopeptidases, tripeptidases, and proline-specific peptidases, which are all serine proteases. Apart from lactic streptococcal proteinases, several other proteinases from nonlactostreptococcal origin have been reported (26). There are also serine type of proteinases, e.g. proteinases from Lactobacillus acidophillus, L. plantarum, L. delbrueckii sp. bulgaricus, L. lactis, and L. helveticus. Aminopeptidases are important for the development of flavour in fermented milk products, since they are capable of releasing single amino acid residues from oligopeptides formed by extracellular proteinase activity (26).

Other dairy enzymes

Other enzymes used for dairy food application include: (i) proteases to reduce allergic properties of cow milk products for infants, and (ii) lipases for development of lipolytic flavours in speciality cheeses. The functional properties of milk proteins may be improved by limited proteolysis through the enzymatic modification of milk proteins. An acid-soluble casein, free of off flavour and suitable for incorporation into beverages and other acid foods, has been prepared by limited proteolysis. The antigenicity of casein is destroyed by proteolysis, and the hydrolysate is suitable for use in milk-protein-based foods for infants allergic to cow milk.

Lipolysis makes an important contribution to swiss cheese flavours, due mainly to the lipolytic enzymes of the starter cultures. The characteristic peppery flavour of Blue cheese is due to short-chain fatty acids and methyl ketones. Most of the lipolysis in Blue cheese is catalysed by Penicillium roqueforti lipase, with a lesser contribution from indigenous milk lipase.

The NOVO process for production of enzyme modified cheese (EMC) uses medium-aged cheese which is emulsified, homogenized, and pasteurized, after which ‘palatase’ (a lipase from R. miehei) is added, with or without a proteinase, and the blend is ripened at a high temperature for one to four days. The mixture is reheated, a paste results which is suitable for inclusion in soups, dips, dressings, or snack foods. EMC technology has been developed to produce a range of characteristic cheese flavours and flavour intensities, for example swiss, blue, cheddar, provolo-nemor or romano, suitable for inclusion at low levels in many products (27). The claims that exogenous enzymes are effective in accelerating ripening have not led to their wide-spread use, possibly due to their high cost, difficulties in distributing them uniformly in the curd, and the possible danger of over-ripening the cheese.

The other minor enzymes having limited applications in dairy processing include glucose oxidase, catalase, superoxide dismutase, sulphydryl oxidase, lactoperoxidase, and lysozymes. Glucose oxidase and catalase are often used together in selected foods for preservation. Superoxide dismutase is an antioxidant for foods and generates H2O2, but is more effective when catalase is present. Thermally induced generation of volatile sulphydryl groups is thought to be responsible for the cooked off-flavour in ultra high temperature (UHT) processed milk. Use of sulphydryl oxidase under aseptic conditions can eliminate this defect. The natural inhibitory mechanism in raw milk is due to the presence of low levels of lactoperoxidase (LP), which can be activated by the external addition of traces of H2O2 and thiocyanate. It has been reported that the potential of LP-system and its activation enhances the keeping quality of milk (28). Cow milk can be provided with protective factors by the addition of lysozyme, making it suitable as an infant milk. Lysozyme acts as a preservative by reducing bacterial counts in milk without affecting the bifidus activity. The scope of application of minor enzymes to milk and milk products has been recently reviewed (29).

Reference

- IDF, Int. Dairy Fed. Bull., 1990, 247, 24–38.

- Stroh, W. H., Genetic Eng. News., 1998, 18, 11.

- Stanley, G., in Microbiology of Fermented Foods (ed. Wood,

- J. B.), Blackie Acad. and Prof., London, 2nd edn, 1998, vol. 1, pp. 263–307.

- Bhoopathy, R., Indian Food Ind., 1994, 13, 22–31.

- Green, M. L., J. Dairy Res., 1977, 44, 159–188. Fox, P. F., J. Food Biochem., 1993, 17, 173–199.

- Farkye, N. Y., Adv. Exp. Med. Biol., 1995, 367, 195–207.

- Novoren, R., Biotimes, 1994, 9, 2–4.

- Green, M. L., in Advances in the Microbiology and Biochemistry of Cheese and Fermented Milk (eds Davies, F. L. and Law, B. A.), Applied Science Publ., England, 1984, pp. 1–34.

- Nishimori, K., Kawaguchi, Y., Hidaka, M., Beppu, T., Gene, 1982, 19, 337–344.

- Foltman, B., in Cheese – Chemistry, Physics and Microbiology –General Aspects (ed. Fox, P. F.), Chapman & Hall, London, 2nd edn, 1993, vol. 1, p. 37–68.

- Meisel, H., Milchwissenschaft, 1988, 43, 71–75.

- Kawaguchi, Y., Kosugi, S., Sasaki, K., Uozumi, T. and Beppu, T., Agric. Biol. Chem., 1987, 51, 1871–1877.

- Mellor, J., Dobason, M. J., Roberts, N. A., Tuite, M. F., Emtage,

- S., White, S., Lowe, P. A., Patel, T., Kingsman, A. J. and Kingsman, S. M., Gene, 1983, 24, 1–14.

- Goff, C. G., Moi, D. T., Kohno, T., Gravius, T. C., Smith, R. A., Yamasaki, E. and Taunton-Rigby, A., Gene, 1984, 27, 35– 46.

- Aikawa, J., Yamashita, T., Nishiyama, M., Horinouchi, S. and Beppu, T. J., Biol. Chem, 1990, 265, 13955–13959.

- Christensen, T., Woeldike, H., Boel, E., Mortensen, S. B., Hjortshoej, K., Thim, L. and Hansen, M. T., Biotechnol., 1988, 6, 1419–1422.

- Leeuw, A. De and Swinkles, B., Voedingsmiddelen Technol., 1993, 26, 9–12.

- Teuber, M., Int. Dairy Fed. Bull., 1990, 251, 3–15.

- Mohanty, A. K., Mukhopadhyay, U. K., Kaushik, J. K., Grover, S. and Batish, V. K. in the Proceedings of the 29th Conference of Dairy Industry, Karnal, November, 1998, pp. 152.

- Dalgleish, D. G., in Advanced Dairy Chemistry, Proteins (ed. Fox, P. F.), Elsevier Sci. Pub., London, 1992, vol. 1, p. 579–619.

- Mehaia, M. A. and Cheryan, Process Biochem., 1987, 22, 185–188.

- Gekas, V. and Lopez-Levia, M., Process Biochem., 1985, 20, 2–12.

- Wilkinson, M. G., in Cheese – Chemistry, Physics and Microbiology – General Aspects (ed. Fox, P. F.), Chapman and Hall, London, 2nd edn, 1995, vol. 1, p. 523–555.

- Krause, W., Partzsch, H., Hassan, Z. M. and Haufe, T., Nahrung, 1998, 42, 162–165.

- Law, J. and Haandrikman, A., Int. Dairy J., 1997, 7, 1–11.

- Kilara, A., Process Biochem., 1985, 20, 35–45.

- Muir, D. D., J. Soc. Dairy Technol., 1996, 49, 24–32.

- Puranik, D. B. and Kanawjia, S. K., Indian Dairyman, 1998, 50, 17–23.

This work is licensed under a Creative Commons Attribution 4.0 International License.