Manuscript accepted on : June 23, 2010

Published online on: 28-12-2010

Optimization of Process Parameter for Protease Production by Fusarium Oxysporum

S. Sajeed Ali

Department of Food and Industerial Microbiology, Rajiv Gandhi College of Food Technology, Parbhani - 431 401 India.

Corresponding Author E-mail:obaide2002@yahoo.com

ABSTRACT:

The investigation was under taken to study process parameter for protease production by Fusarium oxysporum isolated from diseased seed of groundnut. The protease production was studied using gram bran as a substrate and in relation to different incubation time, temperature, moisture level and pH. Maximum protease production was observed on 35oC temperature, 5.5 pH and 120 h of incubation and initial moisture level 50%.

KEYWORDS: Process parameter; Fusarium oxysporum; solid-state fermentation; gram bran

Download this article as:| Copy the following to cite this article: Ali S. S. Optimization of Process Parameter for Protease Production by Fusarium Oxysporum. Biosci Biotech Res Asia 2010;7(2) |

| Copy the following to cite this URL: Ali S. S. Optimization of Process Parameter for Protease Production by Fusarium Oxysporum. Biosci Biotech Res Asia 2010;7(2). Available from:http://www.biotech- asia.org/?p=9789 |

Introduction

Protease is one of the most important commercial enzymes that catalyze hydrolytic reaction in which protein molecules are degraded to peptides. It used in food processing, detergents, diary industry and leather making (Negi and Benerjee., 2006). The protease enzyme constitutes two thirds of total enzymes used in various industries which need to increase production. (Gupta et al., 2002). Protease occurs widely in plant and animals, but commercial proteases are produced exclusively from microorganism. Molds of the genera Aspergillus, Penicillium and Rhizopus are especially use for producing protease. (Sandhya et al., 2005). Protease is extracellular enzymes that can be produced by both submerged fermentation and solid-state fermentation. Solid-state fermentation is especially suited to growth of fungi because of their lower moisture requirement compared with bacteria (Ogawa et al., 1995). Solid state fermentation is simple, low cost, and provides high yields of appropriate enzymes (Wang et al., 2005).

For production of enzyme and its industrial use, isolation and characterization of new promising strains using cheap carbon and nitrogen source is a continuous process. The present study was undertaken to increase protease production of Fusarium oxysporum by using gram bran as a substrate and optimizing the process parameter such as moisture level, temperature, pH, and incubation time for maximum protease production.

Material Methods

Fusarium oxysporum was isolated from diseased seed of groundnut by blotter technique (DeTempe., 1963) and identified (Alexopoulos., 1962). The pure culture was maintained on Czapak- Dox agar containing (g/l). Sodium nitrate 2, KCl 0.5, K2HPO4 1, FeSO4. 7H2O 0.01, Sucrose 3.0, pH, 5.5. for further use. The Substrate was prepared by milling gram bran which was then sieved through 20-40 mesh screens to obtain a particles having diameter between 0.42 and 0.85mm. Fifty gram of substrate was supplemented with 0.83 g K2HPO4 and 0.16g MgSO4 and 10 ml of distilled water, autoclaved for 15 min. at 121oC.

Fermentation was initiated by preparing inoculum of spore suspension of 7 day old culture of Fusarium oxysporum grown on Czapak-Dox agar. The spores were collected in sterile water (Villegas et.al., 1993). A 250 ml flask containing 20gm sterilized 50% moistened substrate was inoculated with spore suspension under aseptic condition and incubated at 30oC for 7 days. After every 12 h of interval 1 gm substrate was harvested from flask and transferred to a test tube containing 5ml phosphate buffer. The contents were homogenized and centrifuge at 2000 rpm for 30 min to remove all particulate matter. The cultural filtrate was filtered through Whatman filter paper and used for enzyme assay.

The protease activity was assayed as suggested by Keay and Wrildi (1970). To 1ml of culture filtrate 1 ml of 2% casein solution was added and the mixture was incubated at 37oC for 10 min. the reaction was terminated by adding of 2 ml 0.4 M TCA (Trichloro acetic acid), again incubated for 20 min. and filtered through Whatman filter paper. One ml of the filtrate was added to 5 ml of sodium carbonate (0.4M) and 1 ml of Folin-Ciocalteus’s reagent and incubated at 37oC for 30 minutes. The absorbance was measured at 660 nm using a tyrosine standard. A unit of protease activity was defined as the amount of enzyme liberated 1ug of tyrosine from substrate (Casein) per minute under assay conditions and reported in terms of protease activity per gram dry fermented substrate.

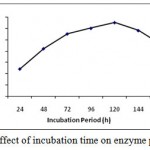

Effect of incubation period

The effect of incubation period on protease was determined by incubating production medium for different incubation periods in day i.e. 24,48,72,96, 120 and 144h.

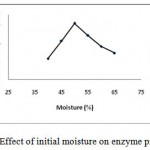

Effect of initial moisture content

Initial moisture of substrate plays important role in mold growth and enzyme production in solid-state fermentation. To determine the effect of moisture substrate were moistened at 45, 50, 55, and 60% with distilled water. The fermentation was carried out for 120h at 35oC.

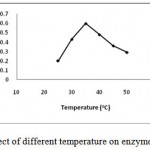

Effect of incubation temperature

The inoculated substrate was incubated at different temperature i.e. 25, 35, 40, 45, and 50oC to observe the effect of temperature, by keeping all other condition at their optimum level.

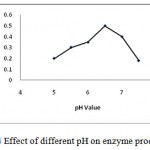

Effect of initial pH

In general practice, the pH in solid-state fermentation is almost never controlled during fermentation, only the initial pH of the substrate is adjusted before inoculation. To evaluate production of protease initial pH of substrate was adjusted at 5, 5.5, 6, 6.5 and 7pH with 1 N HCL or 1N NaOH. The fermentation was carried out at 35oC to study their effect on enzyme production.

Results and Discussion

Proteases are extracellular enzyme that can be produced by both submerged fermentation and solid state fermentation. But solid state fermentation is especially suited to growth of fungi because of their lower moisture requirements. The production of enzyme can be enhanced by optimizing process parameter of solid state fermentation.

The result of present study shows that when Fusarium oxysporum was grown on gram bran as a substrate under solid-state fermentation condition. It secreted protease enzyme, but the amount of protease production varied with incubation time and maximum enzyme production was observed at 120 days of incubation. (Fig.1). A gradual decrease in enzyme units was observed with increasing incubation period clearly indicate that enzyme role as a primary metabolite, being produced in the log phase of the growth of the fungus for utilization of nutrients (proteins) present in solid substrate. (Alagarsamy et al., 2006). Increased in moisture level is believed to reduced the porosity of the gram bran, thus limiting oxygen transfer. While lower moisture content causes reduction in the solubility of nutrients of the substrate and lower degree of swelling. Hence, an optimal level of moisture is required for maximum enzyme productivity. A maximum enzyme titer was found at the initial moisture level 50% (Fig.2).

|

Figure 1: Effect of incubation time on enzyme production.

|

|

Figure 2: Effect of initial moisture on enzyme production.

|

The optimum temperature for maximum proteases production was found at 35oC (Fig.3). A decrease in the yield of protease was observed when the incubation temperature was higher or lower. Effect of initial pH of the substrate on protease production showed that at pH 5.0, there was less enzyme production. As the pH was increased protease production increased gradually and reached to maximum at pH 6.5, a further increased in pH resulted in decreased of protease production (Fig.4).

|

Figure 3: Effect of different temperature on enzyme production.

|

|

Figure 4: Effect of different pH on enzyme production.

|

Conclusion

A strain of Fusarium oxysporum produced maximum protease when grown on gram bran as a substrate under solid-state fermentation. The enzyme production was enhanced by optimizing process parameter. Maximum protease production was observed at 120h of incubation with initial moisture 50% and pH 6.5 at 35oC temperature. Thus gram bran as a substrate and all the above mentioned optimized condition under solid state-fermentation increased the protease production and can be exploited for large scale production of protease enzyme by using agroindustrial waste.

Reference

- Negi, S. and Benerjee, R. Optimization of amylase and protease production from Aspergillus awamori in single bioreactor through EVOP factorial design technique Food Technol Biotechnol. 2006; 44: 257-261.

- Gupta, R, Beg, Q.K., Lorenz, P. Bacterial Alkaline Protease: Molecular approaches and industrial application. Microbial. Biotechnol. 2002; 59:15-32.

- Sandhya, C, Sumantha, A, Szakacs, G. and Pandey, A. Comparative evolution of Neutral proteases production by Aspergillus oryzae in submerged and slid state-fermentation. Process Biochem. 2005; 40:2689-2694.

- Ogawa, A, Yasuhara, A, Tank, T, Sakiyama, T. and Nakanishi, K Production of neutral proteases by membrane surface liquid culture of Aspergillus oryzae IAM 2704. Ferment Bioeng. 1995; 80:35-40.

- Wang, R, Law, R.C.S. and Webb, C. Protease Prodiction and Condition by Aspergillus Oryzae in Flour fermentation. Process Biochem. 2005; 40:217-227.

- De Tempe, J. Proceeding of International seed Testing Association. 1963. Vol. 28.

- Alexopoulos, C.J. “Introductory Mycology” IInd 1962 John Wiley and sons, New York.

- Villegas, E.S, Aubague, L, Alcantara, R, Auria and Revah, S. Solid State Fermentation:Acid protease production in controlled CO2 and O2 Biotechnol. Adv.1993; 11: 387-397.

- Keay, L. and Wildi, B. S. Proteases of the genus Bacillus. I. Neutral proteases. Bioengg.1970; 12:179-212.

- Alagarsamy, S, Paul, D, Chandran, S, George, S, Carlos, R. Rice bran as a substrate for proteolytic enzyme production. Brazilian Archives of Biology and technology. 2006; 49:843-851.

This work is licensed under a Creative Commons Attribution 4.0 International License.