Manuscript accepted on : 12 October 2011

Published online on: --

Evaluation of Physico-Chemical and Microbiological Parameters of Textile Mill Effluents

P. U. Mahalingam1* and R. Chitra1

1Department of Biolology, Gandhigram Rural Institute – Deemed University, Gandhigram – 624 302. Dindigul, Tamilnadu (India).

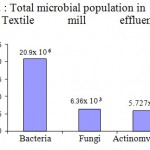

ABSTRACT: The study was carried out to evaluate the physico-chemical and the microbiological parameters in textile mill effluent. The effluent sample was collected from dyeing industry and analysed for various physico-chemical parameters and it was found to be highly polluted. Enumerated the total microbial population of bacteria, fungi and actinomycetes from the textile mill effluent using standard culture media and the count was expressed as colony forming unit (cfu m11).The total counts of bacteria, fungi and actinomycetes of the effluent sample were found to be 20.9 x 10 6 , 6.36 x 103 and 5.727.x 104 cfu/m1 respectively.

KEYWORDS: Textile mill effluent; Bacteria,Fungi and Actinomycetes

Download this article as:| Copy the following to cite this article: Mahalingam P. U, Chitra R. Evaluation of Physico-Chemical and Microbiological Parameters of Textile Mill Effluents. Biosci Biotech Res Asia 2011;8(2) |

| Copy the following to cite this URL: Mahalingam P. U, Chitra R. Evaluation of Physico-Chemical and Microbiological Parameters of Textile Mill Effluents. Biosci Biotech Res Asia 2011;8(2). Available from: https://www.biotech-asia.org/?p=9851 |

Introduction

The Textile Industry Is A Major User Of Water, Starting From Washing Raw Wool Or Manmade Fibre Production Upto Garment Manufacturing (Tewari And Shukla, 1994). Waste Water From The Dyeing, Printing, Processing Of Cloths, Kiering, Bleaching, Mercerizing, Printing, Etc., Is Highly Colored And Can Cause An Imbalance In The Ecological System (Dutta, 1994). Color Was Usually The First Contaminant To Be Recognized In Wastewaters And Affects The Aesthetics, Water Transparency And Gas Solubility Of Water Bodies (Yuxing And Jain, 1999). Strong Color Is One Of The Most Notorious Characteristic Of Textile Mill Effluents. Therefore The Study Was Aimed To Evaluate The Physico-Chemical And The Microbiological Parameters Of Textile Mill Effluent.

Materials and Methods

The Effluent Samples Were Collected From The Outlet Of Textile Mill Dyeing Industry At Chinnalapatti, Dindigul District,Tamilnadu And Analysed For Various Physico-Chemical Parameters Such As Temperature, Ph, Color, Odour, Clarity, Electrical Conductivity, Hardness, Alkalinity, Calcium, Sodium, Potassium, Chloride, Sulphate, Total Solid, Total Dissolved Solid, Total Suspended Solid, Biological Oxygen Demand And Dissolved Oxygen The Textile Mill Effluent Samples By Standard Methods (APHA,1989).

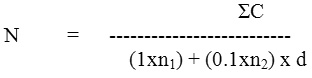

The Textile Effluent Sample Was Serially Diluted Upto 10-7 Using Sterile Distilled Water And 0.1 Ml Of Samples From The Dilutions 10-5 And 10-6 Were Spreaded On Nutrient Agar Plats (For Bacteria) And 0.1 Ml From 10-2, 10-3 Was Spreaded On Martin’s Rose Bengal Agar Plates (For Fungi) And 0.1 Ml From 10-3and 10-4 Were Spreaded On Kenknight Agar Plates (For Actinomycetes). All Plates For Bacteria And Actinomycetes Were Inclubated At 370C For 24 Hrs And 96 Hrs Respectively. Plates For Fungi Were Incubated At Room Temperature For 72 Hrs. After Incubation, The Total Colonies Of Bacteria, Fungi And Actinomycetes Formed In Nutrient Agar, Rose Bengal Agar And Kenknight Agar Respectively Were Counted And Expressed In Colony Forming Unit (CFU) Using The Following Formula:

Where, N = Number Of Colonies;

ΣC= Total Number Of Colonies In All Agar Plates;

N1= Number Of Plates In First Dilution; N2= Number Of Plates In Second Dilution And

D = Dilution From Which The First Counts Were Obtained.

Results and Discussion

Color Present In Dye Effluent Gives A Straight Forward Indication Of Water Being Polluted And Discharge Of This Highly Colored Effluent Can Damage Directly The Receiving Water (Chen Et Al., 2003).The Textile Dye Effluents Have Created Significant Concern Because It Imparts Toxicity And These Dye Effluents Are Objectionable Because Of The Fact That It Reduces Penetration Of Light Through Water Bodies (Saranaik And Kanekar, 1995). Color Present In Dye Effluent Gives A Straight Forward Indication Of Water Being Polluted And Discharge Of This Highly Colored Effluent Can Damage Directly The Receiving Water (Chen Et Al., 2003).The Dyes Release In Water Streams Affect The Aesthetic Merit Of Water And Removal From Water Is Considered As Prerequisite As It Contributes Towards Major Fraction Of The Biochemical Oxygen Demand (BOD) (Banat Et Al., 1996).With This View, The Present Study Was Made To Evaluate The Physico-Chemical And The Microbiological Parameters Of Textile Mill Effluent. The Effluent Sample Was Collected From Dyeing Industry And Analysed For Its Various Physico-Chemical Parameters As Given In Table 1 And It Contains All Types Of Chemical Pollutants In Higher Amount.

Hence It Was Considered To Be Highly Polluted. In This Study, Observed BOD Values Range From 27-80mg/L Which Indicates Effluent Is Highly Polluted. Sulphate Was Naturally Occurring Anion In All Kinds Of Natural Waters. It Was An Important Constituent Of Hardness With Calcium And Magnesium. In This Study, The Chloride Concentration Was 1917 Mg/L Which Indicates The Effluent May Harmful To The Environment (Table 1).

Table 1: Physico-Chemical Parameters of Textile Mill Effluent

| S.No | Parameters | Concentration |

| 1. | Ph | 6.32 |

| 2. | Temperature | 270C |

| 3. | Color Unfiltered Filtered |

Brown Yellow |

| 4. | Odour | Unpleasant |

| 5. | Clarity | Turbid |

| 6. | Electrical Conductivity | 0.09 X 10 2 |

| 7. | Hardness(Mg/L) | 3000 Mg/L |

| 8. | Alkalinity(Mg/L) | 200 Mg/L |

| 9. | Calcium | 19 Ppm |

| 10. | Sodium | 210 Ppm |

| 11. | Potassium | 36 Ppm |

| 12. | Chloride(Mg/L) | 1917 |

| 13. | Sulphate(Mg/L) | 70 |

| 14. | Totalsolid(Mg/L) | 5200 |

| 15. | Total Dissolved Solid (Mg/L) | 5000 |

| 16. | Total Suspended Solid (Mg/L) | 200 |

| 17. | Biological Oxygen Demand(Mg/L) | 27-80 |

| 18. | Dissolved Oxygen (Mg/L) | 64.64

|

The Isolation Of Potent Microbial Species Was One Of The Interests In Biological Aspect Of Effluents Treatment. (Bant Et Al., 1996). In View Of This, The Effluent Sample Was Analysed For The Presence Of Native Microflora. The Total Microbial Population Of Bacteria, Fungi And Actinomycetes Were Enumerated Using Standard Culture Media And The Count Was Expressed As Colony Forming Unit (Table 2).

|

Figure 2 : Total Microbial Population In Textile Mill Effluent.

|

Reference

- APHA. Staandard Methods Of Examinations Of Water And Wastewater, 17th Ed. Amercan Public Health Association, Washington D.C. 11-13.

- Bant IM, Nigam PL, Singh D Nd Marchant R, Microbial Decolrization Of Testile Dyes Containing Effluents: A Review. Biores. Technol.58:217-227 (1996).

- Chen KC, Wu JY, Liu DJ And Hwang SCJ, Decolourization Of The Textile Dyes By Newly Isolated Bacterial Strains. Journal Of Biotechnology. 2003

- Dutta PK, An Overview Of Textile Pollution And Its Remedy. Indian Journal Of Environmental Protechtion. 14(6):443-446 (1994).

- Saranaik A And Kanekar P, Bioremediation Of Colour Of Methyle Violet And Phenol From A Dye Industry Waste Effluent Using Pseudomonas Spp1 Isolated From Fctary Soil. J.App.Bactorial. 79: 85-88 (1995).

- Yuxing W And Jain Y, Decorzation Of Synthetic Dyes And Waste Water From Textile. Wat.Res. 83(16): 3512-3520 (1999).

This work is licensed under a Creative Commons Attribution 4.0 International License.