How to Cite | Publication History | PlumX Article Matrix

Natalia Dementyevna Komarova, Vladimir Leonidovich Kurbatov and Yulia Vladimirovna Litvinova

North Caucasus branch of the Federal Government's Budget Educational Institution of Higher Professional Education "Belgorod State Technological University named after V.G. Shukhov" 24 Zheleznovodskaya Street, Mineralnye Vody, Stavropol Territory, Russia, 357202

ABSTRACT: This article presents the results of studying peculiarities of structure formation in concretes with regard to technogenesis. Dependencies of water and cement requirements on particle size composition of technogeneous sands used as fillers in concretes are shown. Properties of concrete mixes and concretes, depending on main characteristics of fine filler, have been studied and justified. Practical conclusions have been formulated, based on analysis of fine-grain sands for possible wide use of technogeneous sands in production of fine-grain sands.

KEYWORDS: technogeneous sands; technogenesis; structure formation; fine-grained concretes

Download this article as:| Copy the following to cite this article: Komarova N. D, Kurbatov V. L, Litvinova Y. V. Litho-Mineralogical and Physico-Chemical Aspects of Improving Efficiency of Manufacturing Fine-Grain Concretes with Technogeneous Sands. Biosci Biotech Res Asia 2015;12(2) |

Introduction

An integral part of almost all technologies for manufacturing construction materials is mechanogeneous processing of raw materials, including explosion of rock massive, crushing, disintegration, screening, fine grinding, etc. All this leads to changes in physical and chemical properties of the substance.

Due to fine dispersion of massive rocks under the influence of natural forces, new rock formations, new minerals, and mineral deposits are formed.

Studying the fractal nature of substances disintegration process in natural and artificial conditions made it possible for the scientists to develop a mechanical activation theory.

Activation of the substance in geological and technological processes initiates a number of physical and chemical phenomena, their extremes being the distortion of the crystalline grid in minerals, occurrence of point defects and linear dislocations, and rupture of chemical bonds. All these facts form a reserve or “surplus” energy and are characterized by high entropy. Finally, particles comparable to the parameters of the elementary crystalline lattice are formed. Further dispersion inevitably leads to rebuilding (alteration of the crystalline lattice, amorphisation) with corresponding changes in all thermodynamic characteristics of the substance, and its reaction ability. (Zongjin Li, 2011)

The physical and chemical phenomena caused by mechanical effect on solids are especially manifested in grinding of substances. Modern ideas about the inner nature of mechanical and chemical transformations of substances after fine grinding are based on the notion of activating solid reactants with mechanical effect (same as mechanochemical activation, mechanoactivation). The term “mechanoactivation” was introduced by A. Smekal. He defined mechanoactivation as a process of increasing reacting ability of a substance, where the activated substance remains unchanged. If activation leads to changes in the composition or structure of the substance, it is called the mechanochemical reaction. Thus, mechanoactivation, in the understanding of A. Smekal, precedes mechanochemical reaction, and disappears during the reaction.

On the example of statements of other scientists: “Activation will be understood as the process of accumulating defects on the surface of powders’ particles” (A.A. Bobyshev); “In activation, the structural stability of a substance is lost” (M. V. Chaikin); “All processes that accelerate chemical reactions are understood as activation” (E.G. Avvakumov); “Mechanoactivation of solids is determined by defective structure of particles… created in specific conditions of mechanical processing” (N.G. Kakasey). Thus, it becomes clear that mechanoactivation is inextricably related to the changes in the crystalline lattice of the substance.

In the light of the stated above ideas about mineral substances activation during dispersion in various processes occurring in natural or artificial conditions, the synthesis of new formations is regarded as a spontaneously developing exothermic process that does not need an external source of energy i.e., for synthesis; sometimes the energy of the initial substance is sufficient.

It is known that substances in fine dispersion state are characterized by rather unusual properties: they become more chemically active, rapidly react (sometimes with an explosion) with other substances, melt at lower temperatures, get baked better, ensure more robust cakes, etc.; while changes in the properties are caused not only by the dispersion itself, but by activation in the process of disintegration as well. Because of prolonged substance staying in powdered state, “ageing” of the surface is observed, i.e., the surface energy is decreased. (Kosach, A. F., 2003, Krylov, B. A., 2001)

Various physical phenomena accompanying impact or friction eventually become chemical phenomena, and maybe the reason for crystal-chemical transformations. Impact and friction, being the main methods of mechanical effect on solids in the process of grinding for obtaining construction materials, cause the following physical phenomena (Molchanov, V. I. et al., 1988):

- lead do discontinuities in the material and increase exposed surface of its substance;

- distort the crystalline lattice in minerals, cause point defects and linear dislocations that carry the corresponding reserve of “surplus” energy;

- cause elastic and plastic deformations. Relaxation of deformations and residual stresses in solids at low temperature is rather slow, and, therefore, the substance subjected to mechanical effect will have a reserve or “surplus” energy for some time;

- discontinuities in the disintegrated material lead to disruption of chemical bonds in the substance (mechanolism, mechanocracking, etc.). The resulting non-compensated chemical bonds or free radicals have a reserve of “surplus” energy;

- in case of fine grinding, they eventually lead to obtaining particles of size comparable to the parameters of the crystalline lattice. Further dispersion inevitably leads to rebuilding (alteration of the crystalline lattice up to amorphisation) with corresponding changes in all thermodynamic characteristics of the substance and its reaction ability;

- produce heat that heats the disintegrated material;

- simulate emission of electrons and create difference of potential.

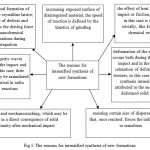

The reasons for intensification of new formations in the substance

Thus, the mechanical effect of impact or friction on solids causes a number of changes in their chemical and crystalline-chemical nature (Molchanov, V. I. et al., 1988). Basing on the analysis of mechanical effect on the disintegrated material, the reasons for intensified synthesis of new formations can be presumably singled out, including production of construction materials (Figure 1).

|

Figure 1: The reasons for intensified synthesis of new formations |

The shown reasoning about hypothetical reasons of mechanochemical reaction shows complexity of causal relationships between mechanical impact a solid and the physico-chemical processes. Between all these disparate phenomena related to physics and chemistry, a certain relationship exists that should be paid enough attention to, both for the purpose of systematizing natural and technogeneous phenomena, and for more complete use of energy generated in the process of mechanical activation.

In recent years, fillers have been used for controlling structure-forming processes in order to obtain materials with extreme characteristics. Their role is diverse: they are substrates for synthesis of new formations, enter into chemical reactions with components of systems, become damping particles slowing down the process of cracks development. Sometimes super fillers are identified, for obtaining high-strength concretes in particular. A wide range of genetic types of rock is used for fillers. (Akhverdov, I. N., 1981., Wagner G. R., 1989, Volzhensky A.V., 1986)

Methodology

Substances’ Internal Energy

In course of disintegration, the internal energy of the substance is supposed to change at this stage preceding discontinuity and/or during crack development. However, while work of dispersion is quantitatively expressed through changes in surface energy, there is no way to measure internal energy of the substance during disintegration. Defining internal energy in the substance during dispersion is in the majority of cases based on indirect changes.

The second method of measuring total energy accumulated by the substance during dispersion is based on changing its solubility. For example, for gypsum it was found that with particle size of 2 μm, saturation of the solution is achieved at concentration of 15.3 mmol/l, and with dispersion of 0.3 μm – at concentration of 18.2 mmol/l.

Changing the reserve of available energy after mechanical impact may be explained by distortion of the crystalline lattice, increasing its defectiveness, or complete destruction with transition of crystalline material into amorphous state. For example, an ideal monocrystal was subjected to mechanical impact that caused formation of point defect in the crystalline lattice, or dislocations. The change in available energy in the crystal is equal to the sum of available energies of all defect and dislocations. If destruction of the crystalline structure led to complete amorphisation of the substance, changes in the available energy, enthalpy, and entropy can be calculated, basing on the energy of the crystalline lattice of the mineral. (Bobryshev A. N. et al. 1992, Kolbasov V.M. and Vasilenko, I. L., 1989)

Numerous experiments have shown that exit points of dislocations are really characterized by increased chemical activity (the method of finding exit points of dislocations by etching the surface of the studied material is based on this fact).

The higher the frequency of mechanical impact is, the higher activation of the crushed material is.

One of the main processes of new formations synthesis in construction material science is dissolution. The assertion that the speed of this process is directly proportional to exposed surface of the solid does not accurately reflect reality. In addition to the dependence on the amount of exposed surface, the speed of dissolution is defined by the characteristic of the surface, the method of preparing dispersed powder, the structure of the substance, and a number of other process parameters as well. For example, it is believed that the main stage that defines the speed of dissolving silica in hydrofluoric acid is the speed of “SiO2 + HF” reaction, but its speed is a function of silica state: for crystalline quartz it will be minimal, for quartz glass – medium, for amorphous silica precipitated from solution – above medium, and for x-ray amorphous quarts obtained by superfine grinding it will be maximal.

Thus, technogeneous sands in the process of formation pass a number of stages of preparation for synthesis of new formations in the «technogeneous sands – clay minerals – water» system. With favorable mineralogical composition, they are more preferable compared to some natural sands.

Water and Cement Requirement, Depending on the Particle Size Composition of Technogeneous Sands

One of the most important integral characteristics of fine fillers for concrete is water and cement requirement.

Existing standard tests provide mainly only a quantitative assessment of the filler, and answer the question whether this filler is suitable for a certain grade/class of concrete. For qualitative of assessment of the influence of the filler on the properties and economic efficiency of concrete (not referring to particular cases, such as filler’s influence on frost resistance, shrinkage, etc.), it is necessary to know the influence of this filler on mobility or water requirement of the concrete mixture and on strength of concrete under compression. (Komokhov P. G., Gryzlov V. S., 1992)

Expressing this influence through some quantitative characteristics of the filler could significantly increase accuracy of technological and technical-economic calculations, and help using computer technologies more efficiently. B. G. Skramatayev and Y. M. Bazhenov proposed the method of testing filler directly in the concrete, which ensures obtaining more veracious technological characteristic of the filler: water requirement, cement requirement, and coefficient of sand strength.

These characteristics, being integral quantitative indicators of filler’s influence on properties of concrete mixture and concrete, were found by comparative testing of cement paste, mortar and concrete mixture.

Results

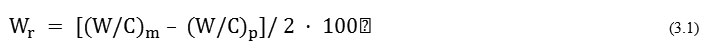

In practice, for defining water the requirements of sand , it is common to first establish (W/C)p of cement paste at which it shows flow of a 170 high cone on a shaking table, which approximately corresponds to its normal density. After that, the (W/C)m of a 1 : 2 mixture on the sand studied is found, where it has the same flow of the 170 mm cone on a shaking table. Water requirement of sand (%) is found by the formula:

The denominator is the number of parts of sand per one part of cement since Wr characterizes water requirement per unit of weight of fillers. Sand water requirement shows how much water should be added after introducing sand into cement paste for preserving agility in characteristic.

For testing cement, standard Volsky sand is used, which has relatively stable composition and grain size. Water requirement for this sand is 4%. Water requirement of any sand may be defined by setting (W/C)m for tested and for standard sand, with which equal agility (rigidity) of the mixture is obtained. In this case:

![]()

Since water requirement of a mixture of filler fractions obeys the rule of additivity, and changes little with slight fluctuations of (W/C) mixtures, Wr may be defined by comparative testing of several compositions of concrete mixtures with various (10 to 15%) content of sand and gravel, but with the same agility.

Test results show that water requirement of fillers fluctuate within wide range, and to make technological calculations, calculations of concrete composition in particular, more accurate, it is necessary to consider the new characteristic of the filler, namely, its water requirement. Real water requirement of the filler in concrete is significantly higher than these values (about 1 to 2%), which were sometimes taken into calculations before for accounting for filler wetting. (Concrete: Building Pathology, 2003, Reinhardt, H.W., 2006)

The influence of the filler on strength of mortar and concrete may be approximately assessed by results of testing mortar and concrete, prepared with the use of tested fillers (ceteris paribus) and by the influence of strength coefficient A in the well-known formula of concrete strength:

Influence of sand on strength of mortar and fine concrete is assessed by results of testing samples of mortar 28 days old. Strength coefficient A for various fillers varies quite markedly. For sands, this coefficient varies between 0.3 and 0.68, for gravel and stone – between 0.34 and 2.75. However, the value of strength coefficient for filler is more influenced, compared to water requirement, by various technological factors, which fact decreases accuracy of this characteristic. Further improvement of the method is required for its successful use, for example, transition to reference compositions of concrete. (Taylor H. F., 2000)

Indicators of fillers’ water requirement make it possible not only to more precisely define water consumption in concrete mixtures with various consistency, but also to define time of its hardening and the limit value of , which ensures obtaining non-laminating concrete mixtures, and validity of linear dependence concrete = f (W/C).

Cement requirement was defined as follows: a mixture with constant ratio C/W=2.5 was prepared, and the amount of screening was chosen to achieve flow of a 170 mm high cone on a shaking table.

Cement requirement was calculated according to the formula:

where V cem.paste is the amount of cement paste in the mixture;

V sand is the amount of sand in the mixture.

Discussion

Improving quality of fine-grained concrete, and strength of items on the base of it, may be obtained by optimization of its structure by improving existing and introducing new characteristics of the material that would make it possible to improve methods of design and calculation for both items and technologies.

Fine filler, being a product of screening crushed rock, is most associated in a concrete mixture with cement paste, and constitutes the mortar part together with it. The more screening product is introduced into the mixture, the higher (ceteris paribus) will the viscosity of the mortar part be (viscosity is required for maintaining coarse filler in suspended state in order to avoid delamination of concrete mixture), and the less will be consumption of cement. However, excessive content of screening product leads to decreasing strength of concrete. Therefore, content of product of screening crushed rock should be optimum.

The product of screening crushed rock has higher hollowness than a mixture of sand and gravel. In case of low content of cement in mixtures leaner than 1:3, cement paste may be not enough for coating grains and filling all voids. In this case, an additional number of pores are formed, resulting from lack of cement paste, which increases the total porosity of concrete and reduces its strength. This explains complexity of obtaining strong enough fine grain concretes with low consumption of cement (200-300 kg/m3), typically occurring in conventional concrete. (Gorshkov V. S., Timashev V. V., Savelyev V. G., 1982, Structure formation in concrete, and physical and chemical methods of its studying, 1980).

For example, if coarse sand in normal concrete is replaced by fine sand, strength is reduced only by 5 to 10%, while in fine grain concrete strength may reduce by 25 to 30%; the maximum strength of sand-based concrete with 1:2 – 1:3 composition, which may be obtained with certain intensity of compaction, sometimes decreases 2 to 3 times. Therefore, for fine grain concretes it is desirable to use coarse clean sands and enrich fine sands with larger fractions of products of screening crushed rock and fine gravel.

Because many regions of the country do not have enough high-quality natural sands, the problem of providing fine concrete fillers for builders in these regions may be solved by using products of screening crushed rock. Purposeful obtaining such filler is an expensive process, and its costs will be in this case significantly higher than the cost of gravel. Therefore, it is necessary to pay special attention to studying the possibility of using products of crushed rock screening in production of crushed stone and in ores enrichment, as filler.

In most cases, stone materials are local building materials, properties of which are not always known and require careful studying (Stupakov G. I., 1986).

At present, the non-metal mining and metal-mining industry yearly store in dumps hundreds of millions of cubic meters of waste from crushing strong mine rock with grain size between 0.14 and 5 mm. One of the reasons for incomplete use of these wastes for fine fillers in concretes is insufficient knowledge of their properties and properties of concrete mixes and concretes based on them.

Properties of artificial sands, concrete mixes and concretes based on them depend on many factors defined by the properties of initial rock, methods of crushing and methods of enriching obtained product. Most significant are strength, structure, and composition of the rock.

In comparing properties of natural and artificial sands, attention is paid to main basic differences between these materials. While the former are mainly quartz, have correct grain shape, and smooth surface, the latter have significant differences in composition and properties of initial rock, shape of grains, and roughness of the surface. Artificial sands have freshly exposed surface. As a result, properties of the latter become different. Interaction between the surface of crushed sand and the cement paste and cement stone is much more complex than in case of natural sands. Without considering this interaction, it is impossible to study the influence of grain size, grain shape, surface roughness and other characteristics of sand on the properties of mortars and concretes. (W. Fleischer, 2000, Herr O., 2001). Based on the foregoing, one can single out several basic factors for obtaining a material that would have properties corresponding to all physico-chemical and exploitation requirements.

Mineralogical composition of fine fillers if compared to coarse fillers has a more significant influence on the properties of concrete. This can be explained by a larger area of contact layer between the filler and the cement stone. Studying the influence of mineralogical composition of crushed stone on strength of concrete, S. S. Gordon found that strength of concrete on carbonate and/or fillers is higher in case of a normal hardening, while in case of steaming, it is lower than strength of concrete on silicate fillers (quartz, chert, and quartzite). He believes that the more individual minerals are included into rock composition, the higher and the stronger is the negative effect of steaming of concrete on its strength.

The shape of sand grains is also a very important and little studied characteristic of technogeneous sands. Until now, the only method of assessing sand grains shape remains the time-consuming method of visual detection of plate- and needle-shaped grains content with a magnifying glass or a microscope. Absence of an easy and reliable method of assessing shape of grains in crushed sand hinders development of its classification for use in practical applications. In relation to technogeneous sands, the method of assessing sand grains shape based on the dependence of specific surface and voidness on grains shape is used. The method consists in defining sand grains shape factor Fs. The sand grains shape factor shows how many times this specific surface of certain sand is greater than the specific surface of sand with the same of grain content but with grains of conventionally accepted spherical shape and with ideally smooth surface. (Müller, H. S. and Wiens, U., 2013)

For natural sands with specific shape of grains, Fs varies from 1.2 to 2.2. For technogeneous sands, the grains shape factor varies from 2 to 4.1. Depending on the mineral-petrographic composition and structure of rock, Fs of the sand obtained in impact crushers is in the range between 2.0 and 2.4, and obtained in other crushing machines – between 2.7 and 4.1.

The particle size composition is one of the main characteristics of fine fillers, which influences directly voidness and specific surface of artificial sands, water requirement of concrete mixture, and, consequently, many properties of concrete mixtures and concretes.

- N. Akhverdov found that each fraction of natural sand in vibration-compacted state has equal inter-granular voidness. Particles below 0.14 mm are mainly of angular shape and, hence, have greater voidness. However, increasing voidness of sand in presence of fractions below 0.14 mm is also caused by their property to be adsorbed onto larger grains, and to form thick films around them. Therefore, presence of particles below 0.14 mm is undesirable.

It was found that use of multi-fraction products of screening crushed rock for fine fillers would make it possible to save up to 80 kg of cement per 1 m3 of concrete. Use of specially prepared technogeneous sand is economically reasonable for concretes of grades 300 and above, since it would lead to saving up to 50 kg of cement per 1 m3 of concrete.

Roughness of fillers is closely related to water absorption by the rock: the higher is the roughness, the higher is water absorption. Activity of filler may be judged upon by the wetting ability of its surface. The more active the surface of the filler is, the thicker the layer of captured and retained water is. In case of low C/W value, greater thickness of retained water should decrease stratification of the cement paste, thus increasing adhesion in the mortar or concrete. In case of high C/W value, formation of thick film of liquid phase on the surface of the filler is impossible, since the ratio of liquid phase films’ thicknesses around the grains of the filler and the cement will be defined by the ratio of their hydraulic activity. In case of high viscosity of the cement paste (due to increased C/W value) and sand with high water-retaining ability, incomplete wetting of the surface of the filler may occur, which would result in only partial sticking of cement paste to the surface of the filler, thus considerably decreasing the bonding force between them. Therefore, for obtaining high-grade concretes, as it is preferable to use fine fillers from rock with good wetting ability, which retain little water on their surface. (Kovalev, V. Z., et al. 2012)

It was found that increasing roughness of the surface, especially the platy shape of grains, increases voidness of sand fractions. Grains compaction degree in case of vibration does not depend on the shape of grains, but depends on surface roughness. Grains with acute-angled shape in case of vibration get compacted to a greater degree.

The type of fine filler, its grain composition, purity, size, and the value of adhesion with the cement stone greatly influence strength of the mortar.

Conclusion

- Analysis of sand stock for fine concretes showed that with all the diversity of genetic types of rocks, deposits with high-quality sands are local in nature and their stock does not satisfy industry needs. Sub-fractioned, poly-mineral sands require individual approach in development of building materials compositions made on their basis, which hinders immensity of their use. The characteristic morphology of grains (roundness) and their surface, including low activity due to long influence of exogenous factors, causes low degree of adhesion to the cement stone, as compared to sands of mechanogeneous origin. In this regard, it seems appropriate to study the possibility of wide-scale using technogeneous sands in production of fine-grain concretes.

- Technogeneous sands feature high grinding ability defined by their genesis, poly-minerality, and presence of minerals with perfect and very perfect cleavage.

- Concrete mixes made with the use of technogeneous sands feature increased consumption of cement. However, the use of fine-grain cements for binder would allow lowering consumption of the brick component by 70 – 80%.

Future research will be focused on developing a universal technology for calculating composition of fine-grain concretes with regard to physical and chemical properties of their components; extending use of fine-grain concretes in all sectors of construction industry; decreasing the share of brick component, and, consequently, the pricing policy for a certain type of material several times.

References

- Akhverdov, I.N., 1981. Basics of concrete physics. Moscow: Stroyizdat, pp: 464.

- Bobryshev, A.N., V.I. Solomatov, V.N. Vyrovoy et al., 1992. Polystructural theory of compositional construction materials. Tashkent: “FAN” publishing house of the Academy of Sciences of the Uzbek SSR, pp: 344.

- Concrete: Building Pathology, 2003. Blackwell Science Ltd. Editor: Susan Macdonald. DOI: 10.1002/9780470773659.

- Gorshkov, V.S., V.V. Timashev and V.G. Savelyev, 1982. Methods of physical and chemical analysis of binding substances. Moscow: Vysshaya Shkola, pp: 335.

- Fleischer, W., D. Grossmfnn and H. Moschwitzer, 2000. Neuerungen bei Fahrbahndecken aus Beton. Teil I. Grundlagen und Fortschritten. Beton, 7: 376-380.

- Herr, O., M. Vachon, Th. Serdan, F. Lerrand and J.M. Balay, 2001. Les materiaux autocompactants essorables de structure (MACES). Etude de faisabilite d’une nouvelle gamme de materiaux hydrauliques pour les assises de chausses. Bulletin des laboratoires des Ponts et Chaussees, 232: 99-103.

- Kovalev, V.Z., N.A. Gutareva, A.F. Kosach, T.A. Urusova and P.Y. Sharypov, 2012. The role of technology and type of sand in structure forming processes in concrete mixtures. Bulletin of the Ugra State University, 3(26): 35–40.

- Kolbasov, V.M. and I.L. Vasilenko, 1989. Hydration formation regulation under cement curing. In the Proceedings of the 2nd International Symposium on Cement and Concrete, 5-8 September 1989, Beijing, 1: 295–297.

- Komokhov, P.G. and V.S. Gryzlov, 1992. Structural mechanics and heat physics of light concrete. RSFSR Academy of Sciences, the Vologda Scientific Center, pp: 319.

- Kosach, A.F., 2003. The influence of technological factors on properties of the mortar fraction of concrete. Bulletin of Higher Educational Institutions. Construction. Omsk, 3: 27-33.

- Krylov, B.A., 2001. Perspective of developing methods for intensifying concrete hardening in the 21st century. Construction Materials, 3: 14-16.

- L., 2011. Advanced Concrete Technology. John Wiley & Sons, Inc., pp: 251-325. DOI: 10.1002/9780470950067.

- Molchanov, V.I., O.G. Selezneva, E.N. Zhirnov, 1988. Activation of minerals during disintegration. Moscow: Nedra, pp: 202.

- Müller, H.S. and U. Wiens, 2013. Beton, in Beton Kalender 2014: Schwerpunkte: Unterirdisches Bauen – Grundbau – Eurocode 7. Eds., Bergmeister, K., F. Fingerloos and J.-D. Wörner. Wiley-VCH Verlag GmbH, D-69451 Weinheim, Germany. DOI: 10.1002/9783433603352.ch16.

- Reinhardt, H.-W., 2006. Beton, in Beton Kalender 2007: Schwerpunkte: Verkehrsbauten, Flächentragwerke. Eds., Bergmeister, K. and J.-D. Wörner. Wiley-VCH Verlag GmbH, D-69451 Weinheim, Germany. DOI: 10.1002/9783433600696.ch4.

- Structure formation in concrete, and physical and chemical methods of its studying, 1980. Eds., Larionova, Z.M. Moscow: Concrete and Reinforced Concrete Research Institute, pp: 139.

- Stupakov, G.I., 1986. Fine sand concretes for industrial and civil construction. Tashkent: FAN, pp: 107.

- Taylor, H.F., 2000. The chemistry of cement hydration. In the Proceedings of the Seventh Conference on thе Silicate Industry, Budapest.

- Wagner, G.R., 1989. Formation of structures in silicate dispersions. Kyiv: Naukova Dumka, pp: 180.

- Volzhensky, A.V., 1986. Mineral binders. Moscow: Stroyizdat, pp: 446.

This work is licensed under a Creative Commons Attribution 4.0 International License.