Manuscript accepted on :

Published online on: 19-12-2015

Managing A Mining Enterprise on the Basis of the Balanced Scorecard

Nazarova Olga Vitalievna and Sekrier Vidana Mihailovna

National Mineral Resources University (University of mines), 199106, St Petersburg, line 21, h. 2

ABSTRACT: The main purpose of the article is to demonstrate the results of applying the balanced scorecard at the enterprises of the mining industry, and to identify the problem areas and promising directions of development of methodological tools and the enterprise development strategy with the use of the key success factors. The strategic balanced scorecard has been formed.

KEYWORDS: mining industry; balanced scorecard; enterprise development strategy

Download this article as:| Copy the following to cite this article: Vitalievna N. O, Mihailovna S. V. Managing A Mining Enterprise on the Basis of the Balanced Scorecard. Biosci Biotech Res Asia 2015;12(2) |

Introduction

Under the current economic conditions, every business entity conducts the analysis of approaches and chooses the modern systems and the best management practices for effective management organization and rapid response to external and internal changes under the conditions of globalization, competition and the progressive development of the environment. Management is generally an influence on the management system aimed at transferring it from one state to another, i.e. management is associated with dynamic processes of the change.

The Balanced Scorecard (BSC) is one of such management technologies [1, p. 27]. The approach integrates the properly formulated strategic goals and mechanisms of effective management, which are aimed at achieving results in the present and future and increasing all capitals of the company (human, financial, industrial, natural and so on). The first step in the creation of the concept was the work titled “Measuring Performance in the Organization of the Future”, which was carried out over one year and was aimed at searching for new alternative methods of performance measurement based on non-financial performance.

Kaplan and D. Norton introduced the Balanced Scorecard in the early 1990s in order to overcome the shortcomings of traditional methods of measuring financial performance and modern changes in the business environment. BSC is a multidimensional measurement system for assessment of the performance and covers both financial and non-financial measures derived from the organization’s strategy and related to each other in a series of cause-and-effect relationships.

Thus, the system was named “Balanced”, because it was built on an integrated approach to the assessment of business performance. Kaplan and Norton used four measures of performance, prospects of which form the organization’s vision: 1. Training and growth; 2. Internal business perspectives; 3. Prospect of customer satisfaction; 4. Financial perspective.

The ultimate goal of a balanced scorecard is achieving the strategic goals and long-term financial results [6, p.123].

Formation of the balanced scorecard is carried out in several stages:

- Modeling;

- Communication and connection;

- Technical integration;

- Organization of feedback.

Organizational business unit (branch, holding, enterprise) as a complex system is characterized by a complex of various indicators. Assessing the level of quality of this business unit implies an integrated quantitative assessment, which reflects the match of results of its work to the strategic objectives and priority customer requirements, which are defined, inter alia, on the basis of the requirements for domestic and foreign markets as a whole.

The general strategy card is based on a corporate plan (or projection) of training and growth. This projection defines the basic elements of the culture, technology and skills that are critical to the organization, if it really intends to carry out its internal processes, and hence the strategy.

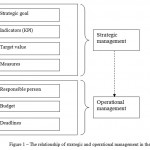

Development of the Balanced Scorecard is completed with developing measures, which are necessary to achieve the strategic goals. The budget, deadlines and a responsible person are usually determined for the developed measures. Thus, the Balanced Scorecard model defines the route from strategic planning to the operational planning, which is presented in Figure 1.

|

Figure 1: The relationship of strategic and operational management in the BSC |

The Balanced Scorecard helps link the corporate vision with the ability to achieve short-term goals, measures and tasks for improvement [7, p.44]. Application of the Balanced Scorecard in the performance assessment allows to:

- Be aware of and be able to determine financial goals and measures of customer satisfaction; quality objectives; growth objectives;

- Monitor the progress of processes using checklists of key performance indicators;

- Reward employees on the basis of key performance indicators.

Despite the variety of the used balanced scorecard templates, there is a common list of templates and forms of documents:

- Tree BSC scheme;

- Tabular BSC form;

- Threads based BSC;

- Strategic card;

- Color coded BSC.

Balanced Scorecard is inextricably linked to key performance indicators (KPI); by itself it merely reveals the results, but not the causes of the problems, requiring further in-depth analysis of factors such as the types of decisions taken by the leaders, and impacts these decisions have on the financial and other types of indicators. As the main tool of effective business management, key performance indicators cover all aspects of the enterprise, take into account the impact, performance, needs of the environment, and relationship of the business processes and communication channels.

Thus, a specific set of “key performance indicators” allows to assess the dynamics of enterprise development and attainment of certain strategy targets at each level of government, as well as to identify problem areas requiring corrective decisions, which is the ultimate focus of the Balanced Scorecard [5, p.7].

Using BSC allows to bring corporate objectives to key performance indicators. To be successful, an enterprise should measure and control all the four key perspectives by developing a set of performance indicators for each direction:

Finance – indicators for monitoring financial performance;

- Customer satisfaction – use a chart to monitor customer satisfaction;

- Quality of business processes – use control charts, Pareto charts and histograms to analyze and improve the speed, quality and cost

- Growth – personnel management, infrastructure and training.

The role and importance of key performance indicators in a balanced system of management in the mining industry.

The mining industry is a set of industries engaged in the exploration and production (mining) of minerals, as well as their primary processing and production of semi-finished products (processing industry).

The indicators of the straight, zonal effect are the production of the mineral (or other works), capital cost for the purchase of equipment, complexity of work, labor productivity of zonal staff and zonal cost of the work. All values of the listed parameters are calculated for both new and basic equipment. The changes in these parameters are also assessed [13, p.14].

Indicators to measure the indirect effect are the indicators of change in sale price, change in production and cost of products sold, indicator of change in the cost of the output for the whole enterprise.

Mining industry, along with the features common across other industries, has specific features that influence the technical and economic performance of its work. These features of the mining industry include:

- Determining influence of natural conditions and factors on the place of territorial location, quantity and quality of reserves;

- Permanent impairment of mining and geological conditions of mineral development. Thus, the depth of mining operations and ash content of coal increase over time, while the metal content of the ore decreases, etc.);

- Nature of reproduction processes determines its high capital intensity.

- The need for new capital investment to maintain the existing production levels along with the commissioning of new horizons. Relative expenditure for these purposes at underground mining method is 45-55% of capital investments allocated for the construction;

- In addition, the reproduction of production capacities in the mining industry is time-consuming. The standard duration of the construction of an open-pit or a mine can be 5 years or more. Time required for deposit opening and creating a network of mining has the main influence on the terms of construction of the mining enterprise [3, p.94].

- Limited service life, which depends on the size of reserves of the mineral at the deposit. This period varies from 20 to 60 years or more. For example, each year several mines that have exhausted their reserves drop out of the coal industry. This situation is specific to the mining industry and increases the cost of simple reproduction.

4. Technology and the method of field development have a significant impact on the technical and economic parameters of mining enterprises. Production of raw materials is carried out by underground and open methods, which differ both by the equipment and the production technology used.

- At the open-pit mining, the basic technical and economic parameters are several times higher than at the underground. Therefore, improving the structure of production by increasing the proportion of open-pit mining is an important area of growth of the mining production efficiency [14, p.92].

- A wide variety of geological conditions specific to the mining industry necessitate the use of various systems of mining, technology, methods and types of mechanization at the same method of work on the deposits.

- The operating conditions of mining equipment are more severe than in other sectors of the economy. Thus, the service life of mining equipment in underground mines is usually not more than 5 years. Therefore, the mining industry is to a greater extent than other industries in need of new equipment resources that allow to update the fleet.

- Labor organization (mobility of jobs, close interrelation of production and work flows, difficult working conditions, and increased danger of the work).

- Structure of production costs. Low material consumption, as mining does not need raw materials. It is a source of raw materials for other industries itself. Therefore, the mining industry is labor-intensive and capital-intensive industry. This is reflected in the structure of production cost, which is dominated by the cost of wages and depreciation.

- Significant fluctuations in the cost of production of 1 ton of the minerals in certain basins or even across the enterprises in the same basin. This is due to the significant influence of natural factors, method of mining, region of mining, etc.

The studies of many local authors found that the higher the share of the industry, which includes the share of primary industries, mainly fuel and steel, the higher the efficiency of the economy of the region in the production of GRP. In turn, the index of tax potential, which directly influences the level of budget efficiency, is almost in direct proportion to the level of production of GRP per capita [12, p.54]. At that, a characteristic feature of the investment process in most countries that are rich in mineral resources is a weak correlation between investment and the process of human capital formation.

At the present time, when many large and rich deposits have exhausted, are under active development or are being suspended in connection with the depletion of commercial reserves, the deposits with relatively short life of mine (10-30 years) or with significant reserves of low quality minerals are increasingly put into operation. Extension of the life of the mining enterprise is possible by increasing the volume of mineral resources involved in the mining based on the review of their conditions (downward) [10, p.87].

In these cases, the investment attractiveness of the project and the enterprise performance can only be achieved through the use of modern technologies or due to scale of operation.

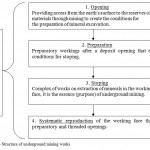

The structure of the mining enterprise (mine or plant) usually includes mines, open-pits, crushing and screening, concentrating or sinter plants, etc. The mineral often lies deep under the ground, and the whole set of processes for extracting raw materials in underground mining are summarized in Figure 2.

|

Figure 2: Structure of underground mining works |

Balanced scorecard is a system of managing the production and economic activity of the enterprise. It’s a way to link the vision of goals with the size of the enterprise and the level of goals. It is designed to provide any link of the management body with systematized information that allows to take better decisions based on full consideration and analysis of the situation, it does not relieve a person of responsibilities to decide. BSC solves the problems associated with the processing of information as well as providing the variance of choice-making and finding its optimum with the resources available and given constraints. Automated control systems and corporate information systems in the mining industry are used to solve these problems in the mining enterprises [15, p.43].

BSC of managing the production of the mining and processing plant or mine consists of several interconnected subsystems allocated according to the following criteria:

- Functional – according to the functions performed by the management body;

- Economic and organizational – depending on the production structure of the enterprise.

The functional subsystem is understood as the part of the BSC that contains a complex of the models and arrays of normative reference data to address specific tasks of managing the defined area of a plant or a mine. The management task is an algorithm (or their combination) required to generate output documents (messages) with a specific functionality to manage the plant or its subdivisions. The concept of the task includes a method of solving this problem, the process of machining and preparation of data for use in decision-making. Functional subsystem includes [11, p.18]:

- Technical preparation of production;

- Feasibility planning;

- Management of the main, auxiliary and servicing production, labor and wages, logistics, distribution and financial activities; and

- Accounting and business analysis.

The tasks on various management levels (site, office, department, workshop, plant) are solved in each of these subsystems. For example, technological preparation of production – the operational management of the processes of technological preparation of production; rationale for the choice made for the technical and organizational solutions; preparation of specifications and statements of the purchase of products; development of technological processes with the calculation of ratios and costs for operations.

The process of implementation of management tasks in BSC includes baseline data collection, their transmission through communication channels, primary processing, data entry and solution of the problem, the output of the solution data to storage media, in the channel, to print (display).

Economic and organizational subsystem is created for the workshops, factories, mines, services and manufacturing sites. The foreman or the sectionman receives information that contains data about the production process in the workshop or on site in its memory and gives the managers the requested data about fulfillment of the program, resource availability, downtime, etc. [11, p.80].

It should be borne in mind that the creation of BSC is not just an automation of the existing management system. The challenge is to develop a management system in relation to BSC by restructuring the management bodies, specifying the rights and duties of departments and officials, workflow, planning, accounting, control, etc., which requires a lot of preparatory work.

Experience has shown that the effectiveness of the implementation of BSC in mines and mining enterprises results in an increase of organizational, technical and economic level of production, acceleration of preparation for production, increase of the content of the valuable element in the finished product, increase in productivity, improvement of the utilization of fixed assets and working capital, which reduces the cost of iron ore products and improves profitability.

Implementation of BSC becomes particularly important under the conditions of highly volatile commodity prices determined in the course of stock trading, which provides not only a reduction in time spent in the calculations, but also accelerated adoption of decisions to improve both production and economic issues.

As you know, all the mining industry can be divided into the following four groups [9, p.76]:

- Fuel extractive industries. These include industries producing solid, liquid and gaseous fuels, including coal, peat, oil shale, oil, natural gas, uranium, etc.;

- Mining industry. These include industries mining iron, manganese, chromite ores, nonferrous ores, precious and rare metals;

- Industries extracting mining and chemical raw materials. These include industries mining potash and other salts, apatites, phosphates, nitrate, iron pyrite, etc.;

- Industries of construction materials. These include industries that mine and process the construction materials directly used for construction, as well as used as a feedstock in the manufacture of bricks, ceramics, glass, etc. These industries mine granite, marble, building stone, limestone, chalk, gypsum, sand, clay, asbestos ore and other industrial minerals. Sets of KPI for each of the groups.

Table 1

| KPI | Mining sub-industries | |||

| 1 | 2 | 3 | 4 | |

| 1. Earnings adjusted for the effect of reserves revaluation | + | + | + | + |

| 2. Operating cash flow | + | + | ||

| 3. Net debt | + | + | + | |

| 4. Frequency of accidents / injuries | + | + | + | |

| 5. Loss of primary containment | + | + | + | |

| 6. Loss of resources during production | + | + | ||

| 7. Replacement cost of reserves | + | + | + | + |

| 8. Production volumes | + | + | + | |

| 9. Shareholder return | + | + | ||

| 10. Processing capacity | + | |||

| 11. Direct emissions of gases | + | + | ||

| 12. Customer loyalty | + | + | + | + |

| 13. Involvement | + | + | + | + |

| 14. Fulfillment of the capacity commissioning schedule | + | + | + | |

Analysis of data on the actual corporate key performance indicators underlying BSC and presented in Table 1 allows to make the following conclusions:

- All enterprises include financial indicators in key performance indicators. These include: revenue from sales, EBITDA, added value, net profit, order backlog, free cash flow, etc. [16, p.67].

- Depending on the specialization and industry sector, the key performance indicators of the enterprise include specific indicators.

- There is no single methodology to create a system of key performance indicators of enterprises. Development of methodological approaches, including for the nuclear industry, is required.

Balanced Scorecard for a mining enterprise is developed in Table 2.

Table 2: Balanced Scorecard for a mining enterprise

| BSC element | Strategic goal | Indicator | Specific value of the indicator |

| 1 | 2 | 3 | 4 |

| Finance | Achievement of the rate of return on invested capital above the average across the industry | Average annual rate of return on invested capital | Over 40% |

| Ensuring sales growth rates above the market rates | Growth of sales revenue | Over 30% per year | |

| Increase in cash flow | Increase in net present value of cash flow | 25% per year | |

| Clients | Maintaining the company’s image | Share of new equipment and new production technologies | Share of new equipment and new production technologies over 60% |

| Improvement of quality-to-price ratio for products | Customer survey | 1st place among competitors according to at least 70% of customers | |

| Position of the priority supplier | Share of sales to regular customers | Over 50% | |

| Quality of internal business processes | Formation of the customer needs | Increase in production volume and production | 8% per year |

| Development of a specific regional market | Increase in the number of new customers in the given region | 35% per year | |

| Reducing the time of preparation and threaded openings.

|

Number of working days between the end of the seam extraction and the beginning of the next | With a probability of 95% – less than 15 days | |

| Dramatic improvement in project management | Share of projects completed in time | 90% | |

| Increased extraction | Reduction of losses in production and transportation of raw materials | 50% | |

| Staff training and development | Continuous improvement of the retraining process | Number of innovations per employee | Over 20 proposals per employee |

| Increase in employee’s satisfaction in the company | Employee satisfaction index | Over 80% |

The strategic card translates objectives of the strategic card into indicators and specific tasks. But the goals and objectives cannot be achieved only by defining them, – for each indicator of the balanced system, the managers have to identify strategic initiatives necessary to achieve the objectives. Initiatives generate a result. Consequently, the implementation of the strategy is achieved through the implementation of initiatives. Plan of action for each area determines the measures and provides the budget. Plan of action for each strategic direction has a situational approach [7, p.119].

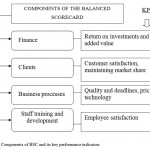

The balanced scorecard allows to determine the basic content of the prospects, and so does the BSC of a mining enterprise, as shown in Figure 3.

|

Figure 3: Components of BSC and its key performance indicators |

After the calculation of key business indicators, conducted on the basis of a number of mining companies, it was concluded that the work of marketing services should be implemented efficiently enough to achieve all the target business indicators of the company [4, p.75]. In this regard, the Table 3 below presents the application purpose and description of the indicators.

Table 3: Application purposes of key business indicators in BSC of mining enterprises.

| Indicator | Indicator application purpose | Indicator description |

| 1 | 2 | 3 |

| Turnover | Maximizing turnover | Market share, as well as the basis for earnings growth |

| Gross profit | Maximizing gross profit | A key business indicator reflecting the overall efficiency of the whole company, the size of the gross profit, and showing how successfully business is conducted |

| Marginality of customer acquisition | Continuous improvement of acquisition efficiency through the search for possible models and methods, the growth of competences and resources | Shows the financial performance of the works on acquisition and the total of the decisions affecting the customer acquisition |

| Marginality of customer service | Continuous improvement of service efficiency through the search for possible models and methods, the growth of competences and resources | Shows the cost-effectiveness of service and the total of the decisions affecting the customer satisfaction with the company |

| Sales-Attritions | Maximizing sales and minimizing attritions | The base for turnover growth, a rate indicating the business growth |

| Percentage of revenue collection in the database of contracts | Bridging the gap between revenue and the database of contracts by optimizing the structure of the advance and postpaid contracts, by optimizing the structure of the warranty, by the quality of the collection of receivables | Shows the quality of the customer liabilities management |

| Volume of overdue receivables in the database of contracts | Minimizing the share of overdue receivables | Shows the financial stability of the company |

| Turnover of the structure | Reducing staff turnover | High turnover of the structure signals a threat to stability and integrity of the organization and is associated with significant costs |

| Staff performance | Improving staff performance | Shows the staff performance, as well as the effectiveness of management solutions to optimize the product and cross functions in the structure |

In contrast to the performance criteria of decision-making, KPIs are indicators that have the desired qualitative or quantitative measurement (“target”), which allows to evaluate the degree of achievement of the strategic goals of the enterprise in dynamic.

The following aspects and challenges in application of BSC in the mining enterprises were examined in this article:

- BSC translates the company’s strategy into four interrelated perspectives and enables specification of the strategic objectives; provides a systematic methodology for transforming the vision and strategy of the organization into the plans of action for individual employees; is an integrated concept of strategy-focused management of the organization [10, p.75];

- It was determined that the advantage of BSC is that the organization that has implemented this system receives the possibility of action in accordance with the strategy at all levels of management and links the various functional areas as a result;

- Peculiarities of BSC for a mining enterprise determined by the nature of technology and the composition of key performance indicators were revealed.

- Factors affecting the technical and economic performance of the mining enterprise determined by its industry specifics.

- A strategic balanced scorecard for a mining enterprise, as well as measures that translate strategic objectives of the card into indicators and specific tasks, were proposed and formulated.

References

- Baskakov, P., 2013. Prospects for the use of the complex automated management system in mining enterprises. Mining, 6(111): 28-34.

- Belyakov, N.N., 2014. Influence of investment efficiency on the borders of open-pits. Mining, 6(118): 87.

- Horvarth&Rartners Balanced Scorecard Implementation, 2008. Moscow: Alpina Business Books, pp: 478.

- Kaplan, R.S. and D.P. Norton, 2003. Balanced Scorecard. From strategy to action (Trans. from English). Mposcow: ZAO “Olympus-Business”, pp: 304.

- Isaeva, N.S., 2014. Evaluating the effectiveness of resource strategies of oil and gas companies on the basis of a balanced scorecard and key performance indicators. Management of Economic Systems, 10.

- Kondratyev, V.B., 2014. Mineral resources as a factor of economic growth and global competitiveness. Mining, 1(113): 6-11.

- Litvinenko, V.S., 2012. Economic problems of mineral raw materials and fuel and energy complex of Russia. St. Petersburg: State Mining Institute (Technical University) named after Plekhanov G.V., pp: 337.

- Mamedova, M.B., E.F. Muradov, R.V. Abbasov and H. Kuliyev, 2014. Formation of balanced scorecard for oil gas enterprises. Problems of Economics and Management of Oil and Gas Complex, 4/VNIIOENG: 42-45.

- Mossakovsky, Ya.V., 2015. Economics of mining industry (3rd edition). Moscow: Business and Service, pp: 525.

- Olve, N.-G., J. Roy and M. Wetter, 2004. Performance Drivers: A Practical Guide to Using the Balanced Scorecard (Trans. from English). Moscow: Publishing House “Williams”, pp: 304.

- Plakitkina, L.S., 2013. Analysis and prospects of development of the coal industry of the major countries in the world, former Soviet Union and Russia in the period through to 2030. Moscow: Publishing house of the Energy Research Institute of Russian Academy of Sciences, pp: 412.

- Romashova, E.A., 2007. Strategic management of the industrial enterprise on the basis of a balanced scorecard, abstract from thesis of Candidate of Economic Sciences, Volga-Vyatka Academy of Public Administration. Nizhny Novgorod, pp: 25.

- Puchkov, L.A. and Yu.A. Zhezhelevsky, 2015. Underground mining (Volume 1, 2nd edition). Moscow: Prospect, pp: 562.

- Tereshenkov, A.S., 2008. Managing enterprise on the basis of the balanced scorecard, abstract from thesis of Candidate of Economic Sciences, Lobachevsky State University of Nizhny Novgorod, Nizhny Novgorod, pp: 27.

- Holodnyakov, D.G., 2014. Determination of the open-pit performance limit that provides an effective deposit development. Mining, 3(115): 91-97.

- Rampersad, H., 2006. Total Performance Scorecard. Moscow: Alpina Business Books, pp: 352.

- Kajl, V.V., 2013. Problems of Implementation of the Balanced Scorecard at Russian Enterprises. Journal of Russian Entrepreneurship, 1(223): 68-72.

This work is licensed under a Creative Commons Attribution 4.0 International License.