How to Cite | Publication History | PlumX Article Matrix

Reducing Energy Consumption in Industrial Enterprises in Modern Conditions

Nataliya Grigorievna Verstina1 and Tatiana Sergeevna Meshcheryakova2

1Federal state budgetary educational institution of higher professional education "Moscow state university of civil engineering", Moscow, Russian Federation. 2Tatiana Sergeevna Meshcheryakova, Yaroslavskoe shousse, 26, 129337, Moscow, Russian Federation.

ABSTRACT: The objectives of the study is to analyze the status and trends of development of industrial enterprises - consumers of energy resources, implementing a policy of energy saving, analysis of management practices of energy consumption using energy service contracts and the development of a conceptual model of the organization of management energy consumption of industrial enterprises using energy service contracts. Application of the proposed conceptual model of the energy cost management for industrial enterprise defines a comprehensive approach to energy management, taking into account the implementation of the mechanism of modern energy service contracts.

KEYWORDS: industrial plant; power; energy service contracts; the conceptual model

Download this article as:| Copy the following to cite this article: Verstina N. G, Meshcheryakova T. S. Reducing Energy Consumption in Industrial Enterprises in Modern Conditions. Biosci Biotech Res Asia 2015;12(2) |

Introduction

The Russian Federation ranks third in the world in terms of total volume of energy consumption – 987 million tons of oil equivalent per year, after China and the United States with their annual energy consumption 3 474 million and 3 266 million tons of oil equivalent, respectively (World Bank, 2008, 2015) . High amounts of energy, and significant energy costs have led to the fact that the issues of improving energy efficiency, reduce energy intensity of production and the widespread implementation of energy-saving technologies in Russia now acquired special urgency.

Under the state program “Energy conservation and energy efficiency for the period till 2020”, “Energy and Energy Development” and “Energy Strategy – 2035”, the formation of an energy-efficient society is one of the priorities of state policy (The Ministry of Energy, 2014; Russian Government, 2008). Presidential Decree № 889 of June 4, 2008 “On some measures to improve energy and environmental efficiency of the Russian economy,” set the goal to improve energy efficiency, the implementation of which should ensure the reduction of energy intensity of gross domestic product by 2020 at least 40% compared to 2007 in a sustainable and environmentally responsible use of energy resources (President of the Russian Federation, 2008).

Based on the concept of long-term social and economic development of Russia until 2020 there is going transformation of the Russian economics from the resource-feedstock type to the resource-innovative one. It requires promoting strategic initiatives in the field of energy efficiency. Active getting of investments to develop activities in the field of energy conservation and energy efficiency is one of the main objectives of the subprogram “Energy conservation and energy efficiency” as part of the program “Energy efficiency and energy development”.

According to the energy balance of the Russian Federation Federal State Statistics Service, the largest consumer of electricity and thermal energy is an industrial production: the annual energy consumption of 197.4 million tons of equivalent fuel energy and 76.1 tons of fuel million heat (BP Group, 2013, 2014; IEA, 2014). The high level of energy intensity of industrial production suggests the presence of significant reserves to reduce ongoing operating costs. According to experts, most branches of industry, including machine tools, implementing the state policy of energy saving, can significantly reduce energy costs.

High energy industries cause significant economic problems in their work: the high costs of production and, consequently, high production costs, lack of working capital, product marketing difficulties and low liquidity. The low efficiency of domestic enterprises entails a slowdown in the economy as a whole.

Research in the field of energy efficiency show positive results in a set of measures to reduce energy costs. In the structure of production costs, their share is gradually reduced and thereby released financial resources that can be directed at the development of industrial activities. On this basis the competitive advantage of the products, which are essential ingredients for success in solving the problem of import substitution strategy in the current environment.

Among individual factors significantly impede the realization of state policy in the field of energy saving in the industrial enterprise, are the lack of systematic management of current and investment costs associated with energy efficiency, a well-defined set of tasks of process management of energy conservation, and the lack of procedures, regulations and internal standards to ensure efficient the implementation of management decisions to reduce energy consumption. In this connection special importance is the development of an integrated methodological tools for energy cost management of the industrial enterprise.

Methodology

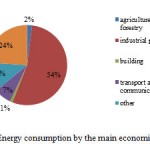

According to the energy balance of Rosstat, the industrial production that is the most energy-intensive branch consumes more than half of the total energy (Figure 1) (Federal State Statistics Service, 2013).

|

Figure 1: Energy consumption by the main economic branches |

Analysis of trends in industrial production and the structure of production costs showed that the fuel and energy costs are from 1% to 40% of the total prime cost for different industry branches despite the relatively low energy prices in Russia comparing to the world market prices. The industrial enterprises uses totally 125-130 million tons of coal equivalent, accounting for over a third of primary fuel-energy resources (FER) and over 50% of electricity resources in our country. The manufacturing industry is the largest end-user in the Russian Federation, it accounts for about 30% of total energy consumption. The main energy saving potential is concentrated in the most energy-intensive branches, which include the enterprises with the highest absolute rates of consumption of fuel and energy (metallurgical, chemical, and petrochemical enterprises), as well as the enterprises with the higher input of fuel and energy resources into production costs (production of machinery and equipment, production of building materials, cellulose-paper industry).

The use of a unified energy balance (IFEB) is a methodological tool for analyzing the potential energy savings, as well as informational basis for the development of long-term programs in the field of energy saving and energy efficiency (GOST 31607-2012; GOST R 51750-2001). IFEB means a balance of production, conversion and consumption of all types of energy.

Economic growth in the level of the individual industrial enterprise needs additional investments. In this regard, industrial policy should form a strategy of innovation and investment development, which had to base on a selection of administrative decisions in the field of energy efficiency. Increased investment activity in the energy modernization of enterprises is one of the key conditions for their development.

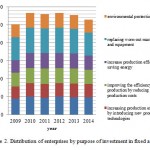

Based on the data by the Federal State Statistics Service (“Distribution of organizations to assess the objectives of investing in fixed capital”) and examination of the information about the investment activity of a number of organizations and investment intentions of entrepreneurs, it is learned that the main purpose of investment during the last 10 years is the replacement of worn-out machinery and equipment (Figure 2).

|

Figure 2: Distribution of enterprises by purpose of investment in fixed assets |

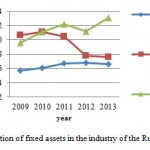

For many businesses, energy efficiency is closely connected with the production technology, and therefore it be increased on the way of replacing the existing equipment with energy efficient one. The need for modernization of the production equipment is confirmed by statistical information about the change in the degree of deterioration of different type industrial production fixed assets in Russia (Figure 3). The conclusion follows that a number of problems related to high energy products, lack of efficiency of generation, transmission and distribution of energy, low reliability of power supply, insufficient or low reliability of information on the energy infrastructure, excessive power consumption obsolete primary process should be solved.

|

Figure 3: Depreciation of fixed assets in the industry of the Russian Federation,% |

The high power-consuming of production should be recognized as the main problem, in view of the fact, that it leads to increasing of the cost of production and, as a result, to reducing of the competitiveness of enterprises. Note that the power-consuming is a power consumption for the main and / or auxiliary processes in the manufacture and services based the existing technologies. According to technique of the definition of energy consumption in the production of goods or services in technological energy systems, the high power-consumtion arises from the following reasons:

- Over or under loading of the main technological equipment;

- A violation of technological rules;

- Climate mismatch inside the production areas to established technological requirements for functioning equipment;

- Observance of mandatory requirements for operating modes of power supply systems;

- Methodological errors in the calculation of energy balances (GOST 27322-87);

- Observance of requirements to enterprises and violation of the order of works;

- Errors in the evaluation of the energy capacity of production;

- The unused potential of a secondary energy.

To improve the energy efficiency of industrial enterprises it needs to implement the following set of measures:

- Energy revision of enterprises (energy audit), preparation of energy passports for all objects;

- Mandatory measures for replacement or installation of metering equipment and the introduction of automated energy accounting systems in power-intensive facilities;

- The introduction of energy-saving technologies, which includes the installation of energy-saving equipment and implementation of measures for energy saving;

- Energy efficiency in buildings, it is a set of organizational, legal, technical, technological, economic and other measures aimed at reducing the amount of energy used while maintaining the benefits from their use (including the volume of production, work performed, services services);

- Organizational (or behavioral) energy saving, that suggests to run measures to improve the culture of energy saving company’s employees, as well as institutional arrangements for regulation of energy consumption throughout the day. Such actions should be implemented in the enterprises where the higher energy consumption is caused by low loading of machinery and equipment, as well as spasmodic functioning of primary equipment associated with long periods of inactivity (units are working without disconnection from the power supply). It is assumed that there is no a restructuring to produce another type of product or there is no a scheduled maintenance of equipment.

In accordance with the law # 261 of the Federal Law (Art. 16 para. 1), there are a number of organizations that are required to conduct an energy audit at least once every five years (Federal Law of the Russian Federation # 261, 2009). Firstly, the enterprises engaged in production of oil, coal, natural gas, as well as production, processing and transportation of various kinds of energy are as objects of energy audits. Energy audit is conducted to identify sources of wasteful energy consumption and unnecessary energy losses. The indices of energy efficiency should be revealed; potential problems of energy savings should be identified; comprehensive energy saving programs should be proposed. Energy audits can be classified by the two main criteria: the timing and the extent of work. Depending on the purpose, the audit is allowed to combine any above types, both by timing and by volume. Energy audit of enterprises involves the following activities:

- Selective or total survey of energy resources;

- Instrumental analysis (Thermal imaging survey) of enclosing structures of buildings, electrical equipment, technological equipment, and so on, etc .;

- Development of recommendations aimed to improvement of the efficiency of energy equipment and reducing the power consumption in organizations;

- Development and approval of the energy passport of enterprises in regulatory authorities.

The main mechanisms for implementation of energy saving measures are contracts on energy saving, concession agreement, and energy service contracts (ESC). Nowadays, the energy service agreement (contract) is the most advanced energy-saving mechanism. Under federal law number 261 of the Federal Law “On energy saving”, the subject of ESC is the implementation provider (Energy Service Company – ESCO) actions aimed to energy saving and energy effective use of energy resources by the customer. Currently, there are only approximate requirements for ESCO. It creates uncertainty in matters of contractual obligations in the course of interaction between participants of ESC. Features and advantages of ESC are integrated approaches to energy efficiency of an enterprise.

Energy contract is a mixed form of the contract aimed to energy efficiency and includes a number of works of all kinds of energy saving (including energy diagnostics) ESCO in the company of their own and / or borrowed funds. At the same time, the company does not initially bear the costs and compensate the costs of the ESCO using savings of ongoing operational expenses, which are obtained due to energy-saving measures. Thus, the company is introducing a new energy-efficient technologies and equipment without incarring financial costs (ICF, 2007).

Taking into account the application of the mechanism ESC there is developed a conceptual model of the organization of management of industrial enterprise energy consumption (Figure 4) (Meshcheryakovа, 2015).

Formation of the conceptual model is based on the laws of development of industrial enterprises and the Russian economics as a whole:

- Low efficiency of domestic enterprises leads to a reduction in the rate of growth of the economics as a whole;

- Industrial end-users of energy, implementing energy conservation policies create conditions for increasing the competitiveness of the industrial sector and the entire economy of the Russian Federation;

- The organization of energy management at the industrial enterprise is aimed, inter alia, at reduction of the production cost and at enhancement of the competitiveness of enterprises by streamlining the structure of energy consumption and using efficient energy consumption management system, that is a part of the overall management system for the enterprise (GOST R ISO 50001-2012).

Construction of a conceptual model is made on the basis of the following assumptions:

- The conditions of formation of the conceptual model cteate the outer contour of the system.

High energy intensity of industrial enterprises causes significant economic problems in their work: the high costs of production and, consequently, high production costs, lack of working capital, difficulties in marketing products and low levels of liquidity. These factors determine the low competitiveness of domestic industrial products and entails a reduction in the growth rate of the economy as a whole. In these circumstances, the state policy aimed at energy conservation and energy efficiency of industrial enterprises, according to the government programs and the Energy Strategy of the Russian Federation.

2. The conditions of formation of a conceptual model to identify design goals.

State policy in the field of energy conservation is aimed at improving the energy efficiency of industrial enterprises. This goal can be achieved, provided the industrial enterprises to reduce costs, and as a consequence, reduce the cost of production of industrial enterprises.

According to the state program of energy saving and energy efficiency for the period up to 2020, one of the areas for the implementation of the program activities is the name of the industrial sector. Improving the energy efficiency of industrial predpriyatty realized through measures that have been agreed under long-term (5-10 years) target agreements with the Government of the Russian manufacturers of the most energy-intensive industrial products and (or) the introduction of ESC for the modernization of the main production equipment. Development of target agreements based on the results of energy audits, which are conducted every 1 to 5 years in energy-intensive industrial plants, whose energy costs exceed 10 million units in the national currency in year.

3. The basic elements of the conceptual model is a form of organization of energy-saving measures. Mechanisms of realization of energy saving measures are contracting contract for work on energy efficiency, ESC and the concession agreement.

The first and most simple form of energy saving measures – a contract agreement, which is expected to attract an outside company to carry out one or more energy-saving measures. The contract is governed by the Civil Code (Chapter 37 of the Civil Code).

ESC (energy service contract, energy performance contract) – agreement, the subject of which is the implementation of Executive action aimed at energy conservation and energy efficiency use of energy resources by the customer. This agreement includes a number of specialized ESCO, the set of activities for the implementation of energy-saving technologies at the customer at the expense of credit funds attracted by the ESCO. Payment attracted financial resources and the work performed by the customer after the implementation of the project at the expense of the savings resulting from the implementation of energy-saving technologies. The agreement is usually concluded for a period of validity of ESC, during which payments are made.

Unlike traditional approaches to energy saving, where the responsibility of energy saving measures in the form of energy audits and implementation of the planned project rests with the company as non-core and secondary objectives on which to spend its own funds and thus carry the risks associated with the implementation of the project approach ESC allows you to lay the basis of the whole complex of necessary measures and the associated risks to the ESCO.

|

Figure 4: Conceptual model of organization management PP energy consumption through the use of ESC |

The concession agreement is a form of public-private partnership, which implies the involvement of the investor in the effective management of the facility, which is state property or services on mutually beneficial terms. The concession agreement provides that the grantor (state or municipality) transfers to the concessionaire the right to exploit natural resources, infrastructure, plant and equipment. Instead, the grantor receives compensation in the form of one-time (lump sum) or recurrent (royalty) payments.

Concession Agreement are regulated by the Federal Law #115 from 21.06.2005 “On Concession Agreements”, taking into account the last changes (Federal Law #152, 2010). According to the Federal Law # 115 the subject of the concession agreement is the reconstruction of the object (its reconstruction activities through the introduction of new technologies, mechanization and automation of production, modernization and replacement of obsolete and worn-out equipment with new more efficient equipment, etc.).

By using this form of organization of energy-saving measures ownership of the facility is the subject of the agreement is reserved for the public party (grantor).

Contract for the implementation of energy saving measures and the concession agreement does not have the high efficiency based on the following reasons:

- Contracting agreement is usually carried out within the constraints in terms of financing, since in this case industrial company invests its own or borrowed credit funds to implement energy-saving measures;

- Concession agreement is a complex form of organization of energy-saving measures at which weakens the role of managers of industrial enterprises;

- Concession agreement on energy efficiency in the industrial plant includes a number of the head of the obligations related to the transfer to the concessionaire for the construction of new and / or upgrading of existing assets, as a rule, long-term in mind that there are long-term property and legal relations between all parties to the agreement.

Based on these arguments, it can be concluded that for the purposes of reducing energy consumption in an industrial plant must use the most simple and modern mechanism that takes into account the limitations of its own sources of funding for the company in the implementation of complex energy-saving measures. This is precisely the form of ESC.

ESC should contain:

The planned value of energy savings, which should be achieved as a result of energy-saving measures as part of ESC;

Duration of the ESC, equal to the period not less than necessary to achieve the set value of energy savings;

Other terms of ESC, established by the legislation of the Russian Federation.

The set of measures ESC includes:

- Investment energy audit (definition of financing mechanisms);

- Energy audits;

- Preparation of the investment business plan;

- The opening of financing;

- Design works;

- Supply and installation of energy-saving equipment;

- Training of industrial enterprises;

- Operation of the object, the compensation investment through savings of an industrial enterprise.

ESCOs, in turn, is directly interested in the qualitative execution of works, as recoupment and the profit depends on the size of the savings now as a result of project implementation.

Comparing with the traditional approach of ESC to the modernization of industrial enterprises (at their own expense) has the following advantages ESC:

- the interest of the ESCO to maximize savings through long-term contracts with limited investments;

- absence of financial risk for the industrial enterprises (ESCO guarantees financial savings and assumes all risks for the project);

- does not require a financial investment on the part of the industrial enterprise – the project is funded by a third party (usually by credit institutions), and the remuneration provided guaranteed savings.

Since the ESC is long-term, it is necessary to think in advance cost payment methods and conditions section of the savings for the entire duration of the ESC. In world practice, often the following types of contractual arrangements:

The division of income from savings (Shared Savings).

Using this method, an accurate count of income from savings held clear and understandable methods dostupnymidlya check. The share of the parties to the income from the savings calculated in advance. The share is included ESCO loan payment and the agreed payment for services, divided by the duration of the contract. All figures are specified in advance, so that all possible risks associated with the planned efficiency vozmozhnymnedostizheniem assumes ESKO.Soglasno international experience, the percentage of the customer’s income from savings is about 20%;

Fast return on investment (First-Out, First Pay-Out).

With this method the ESCO receives 100% of the savings until the full cost of the measures. In contrast to the method of revenue sharing, which are calculated in advance the proceeds of the economy, in this case in advance calculated and negotiated the costs of energy-saving measures. Often there is a combination of the above methods;

Guaranteeing savings (Guaranteed Savings, Chauffage).

Using this method, the ESCO guarantees the customer snidenie energy costs. In addition to the introduction of energy saving project, the ESCO checks zakazchika.V energy economy over the life of the contract ESCO pays the utility bills of the customer. The customer also pays a fixed amount equal to the average of 85-90% of payments for the energy-saving measures. Fakticheskayavelichina the savings will not affect the payments directly to the customer.

4) The central block of the conceptual model is the technique of organization of energy consumption management.

The technique of the organization of management of power consumption in the conditions of use of ESC include the following components:

- Determination of energy savings reserves.

Based on the diagnostics of the level of energy consumption (by the energy audit) the company reserves on energy saving are determined;

- Embodiment of a complete list of possible energy saving measures.

The results of the diagnostics, including those formed in the audit report, a list of energy saving measures is subjected to internal examination at the enterprise, based on which a decision on the composition of ESC is taken;

- The implementation of energy saving measures based on ESC.

In accordance with the processing approach based on the principles of ISO 50001: 2011 a planning cycle of continuous improvement and a system of control and energy consumption are carried out (GOST R ISO 50001-2012);

- Evaluation of the effectiveness of the proposed energy saving measures and monitoring.

On the basis of guidelines developed for the economic evaluation of energy saving measures, assessment the effectiveness of measures and monitoring of power systems businesses can be done, taking into account modern approaches.

Block certain embodiments, the energy-saving measures is an integral part of the organization of energy management techniques in the enterprise.

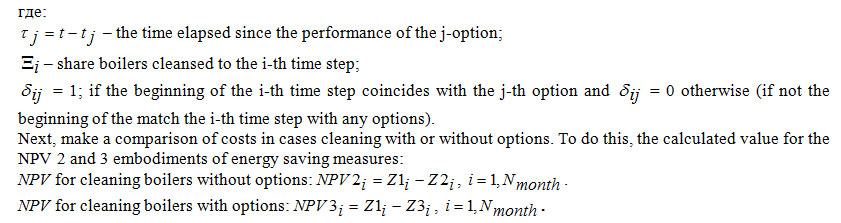

It should be noted that the algorithm requires a comparison of the three trajectories of cash flows:

Option 1 – static system (the case is the extrapolation of the existing energy system);

Option 2 – dynamical system (one-time investment in one or more energy efficiency measures);

Option 3 – dynamical system (phased investment in energy efficiency measures, taking into account the scale of the project).

The appropriateness of energy saving measures taken on the basis of a comparison of these options.

In the case of a mandatory requirement of modernization of capacities, the examiner should choose the second or third option 3 for the project. This choice can be made on the basis of a preliminary analysis of the technical characteristics of the equipment and the source of formation of investment funds. In exceptional cases, the one-time special-purpose financing and limitations of the technologies used or the equipment chosen the second option.

Phased implementation of energy saving measures provides for the calculation of the economic effect of keeping the cost of the option. For this purpose, the study proposed a method for calculating the economic effect to the cost of real option.

Total efficiency rate of energy saving measures should be adjusted to the value of the real value of the option (Limitovsky, 2004; Lawrence G. McMillan, 1986):

where:

W – the value of the project, expressed in monetary terms;

СF (Cash Flow) – cash flow, including the costs of ESM, current operating cost savings over the lifetime of energy saving equipment (tn-t1), the cost of outsourcing the maintenance of engineering systems and equipment ESC (tn-t0);

tn – t0 – standard service life of the equipment.

C – Cost of real option.

To determine the value of real option valuation model used by premium European call options Black-Scholes:

![]()

where:

N (d) – an integral function of the normal distribution.

σ – standard deviation of stock returns over the period. For real options, this value takes into account the “asset price volatility” (estimated market risk). For real assets is a way to assess the statistical analysis of historical data;

S – the current value of the underlying asset (the present value of cash flows from the sale of the investment opportunities that the company will get as a result of the investment project);

X – the exercise price of the option (for real options is the cost of the project);

e – the number being the base of the natural logarithm (rounded value of e is 2.71828);

r – a short-term risk-free rate of return;

t – time prior to the expiration of the option (option contained in the implementation of capacity) or the time until the next time a decision point.

The last block is the formulation of the results to match the goals.

Energy-saving measures, including the upgrading and replacement of equipment with modern, high-class energy efficiency ones, will improve the quality of products, and the reduction of outside energy consumption (the costs associated with the operation of buildings of industrial enterprises), will reduce the overhead cost structure. As a result, the energy capacity and production costs are decreased and industrial competitiveness is increased for an enterprise and, as a consequence, for the whole Russian economy.

Results

Scientific novelty of the research is represented by the following main terms and the results:

- Conceptual model of the organization of management in energy costs of industrial enterprise, which takes into account the importance of reducing the high energy intensity of industrial production in terms of import substitution. Distinctive features of the conceptual model is the format of the organization of energy saving measures based on the use of the mechanism and organization of ESC control system power consumption.

- The method of organization of the management of energy consumption in industrial plants, including the definition of reserve energy savings, the formation of a complete list of possible energy saving measures, the implementation of energy-saving measures on the basis of ESC, the planned assessment of the effectiveness of energy-saving measures and monitoring results.

- The methodical approach to the implementation of ESC in industrial enterprises, the distinguishing feature of which is to focus on the cycle of continuous improvement and an increase in the functions performed under the ESCO project.

- A methodical approach to the assessment of the cost-effectiveness of energy-saving measures for the determination of ESC, taking into account the application of the theory of real options in terms of phasing ESC.

To study the feasibility of the proposed methodical approach to evaluating the cost-effectiveness of energy-saving measures carried out its testing based on the available raw data Energy Performance of industrial enterprise.

The calculation is shown for the event – cleaning the internal surfaces of the boiler descaling acid-free alkali-free method.

Option 1. The cost of heating, if the project is not carried out, for each month are calculated using the following formula:

where:

N – number of months in a project (in this case N = 36)

Z10 = 0- Start-up costs;

Δt – time step (in this case Δt = 1 month);

z1 – heating costs per unit time (for 1 month) if the boilers will not be cleaned;

kj – The discount rate.

The discount factor changes from year to year, and in the first year it is assumed to be = 1.

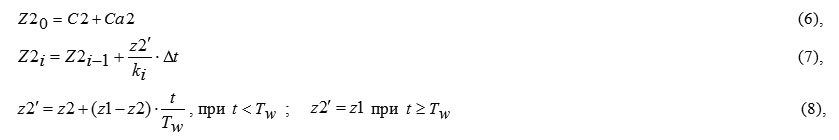

Option 2. Clean all boilers at the company will be held at the same time, while the costs are calculated for each month are determined by the following formulas:

where:

С2 – the cost of cleaning the boiler;

Са2 – the cost of the additional equipment required for cleaning;

z 2’– expenses for heating per unit time in the case prochischknnyh boilers with the gradual formation of scale.

z2 – expenses for heating per unit time (for 1 month) immediately after cleaning the boiler.

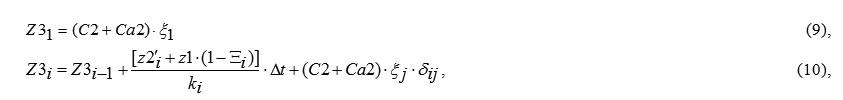

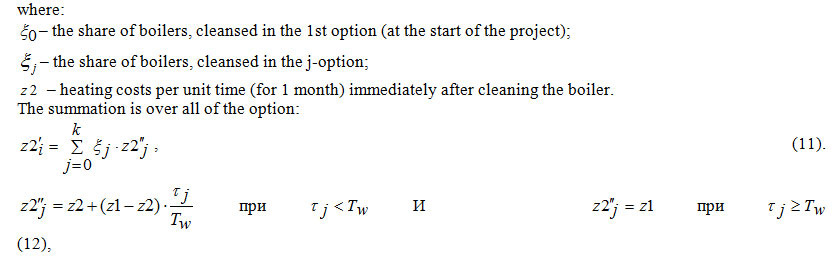

Option 3. Cleaning the boiler will be held with options. Heating costs are calculated by the formulas:

Discussion

An analysis of official data and research on the costs of energy resources and the development trends of the various sectors of the economy, it was found that the greatest potential for energy savings in Russia is the industrial sector. Formation of the industrial energy sector is one of the priorities of state policy.

Based on the research of energy management in the conditions of use of ESC in an industrial plant it has been revealed that, in contrast to the traditional approach to energy conservation-based approach allows the ESC to assign responsibility for the implementation of the required measures and risks in achieving the stated results in the ESCO.

Application of the proposed conceptual model of the organization of management in energy costs of industrial enterprise defines a comprehensive approach to energy management of an industrial enterprise, taking into account the implementation of modern mechanisms of ESC. The developed method of organization management system power consumption and methodical approach to the implementation of ESC in an industrial plant as part of the conceptual model provides an opportunity to implement energy saving measures to meet modern standards for managing energy costs.

Substantiation of efficiency of energy-saving measures as part of ESC should be implemented on the basis of a methodical approach to the assessment of cost-effectiveness of energy efficiency measures, taking into account the cost of the option. With the implementation of energy saving measures in several stages of the project increases the value on the basis of decision-making capabilities (termination or suspension of the project, a change in the pace and scope of the project), provide “flexibility” of the strategic management of investments. The developed method of estimating the cost-effectiveness of energy saving measures defines as a supplement to the index NPV value of real option.

Conclusion

n summary, the author of the obtained results, which are as follows:

- An analysis of official data and research on the costs of energy resources and the development trends of the various sectors of the economy, it was found that the greatest potential for energy savings is the industrial sector. Formation of the industrial energy sector is one of the priorities of state policy.

- On the basis of studies of energy management in the conditions of use of ESC in an industrial plant has been revealed that, in contrast to the traditional approach to energy conservation-based approach allows the ESC to assign responsibility for the implementation of the required measures and risks in achieving the stated results in the ESCO.

- Application of the proposed conceptual model of the organization of management energy costs of industrial enterprise defines a comprehensive approach to energy management of an industrial enterprise, taking into account the implementation of modern mechanisms of ESC. The developed method of organization management system power consumption and methodical approach to the implementation of ESC in an industrial plant as part of the conceptual model provides an opportunity to implement energy saving measures to meet modern standards for managing energy costs.

- Substantiation of efficiency of energy-saving measures as part of ESC should be implemented on the basis of a methodical approach to the assessment of the cost-effectiveness of energy saving measures, taking into account the cost of the option. With the implementation of energy saving measures in several stages of the project increases the value on the basis of decision-making capabilities (termination or suspension of the project, a change in the pace and scope of the project), provide “flexibility” of the strategic management of investments. The developed method of estimating the cost-effectiveness of energy saving measures defines as a supplement to the index NPV value of real option.

In order to study individual dissertation topic should be explored especially the current energy consumption in relation to specific sectors and to formulate recommendations for their model.

Of particular relevance in the near future will acquire a value of “white” and “green” certification for industrial enterprises, which in this research just mentioned. However, these tools will allow to consider another source of added value in the formation of the model valuation project to reduce energy consumption and to identify the factors increasing the competitiveness of enterprises.

References

- Energy Efficiency in Russia: Untapped Reserves. A study by the World Bank and the Center for Energy Efficiency. (2008, September 17). Retrieved from http://www.cenef.ru/file/FINAL_EE_report_rus.pdf.

- World Bank Revises Its Growth Projections for Russia for 2015 and 2016. (2015, June 1). Press release World Bank. Retrieved June 2, 2015, from http://www.worldbank.org/en/news/press-release/2015/06/01/world-bank-revises-its-growth-projections-for-russia-for-2015-and-2016.

- The Ministry of Energy, 2014. The draft energy strategy – 2035. Russian Federation

- Russian Government, 2008. The concept of long-term socio-economic development of the Russian Federation for the period till 2020. Russian Federation.

- Russian Government, 2014. Resolution #321 “On approval of the state program of the Russian Federation” Energy efficiency and energy development”. Russian Federation.

- President of the Russian Federation, 2008. Decree #889 “On some measures to improve the energy and environmental efficiency of the Russian economy”. Russian Federation.

- The main provisions. Forecasts of development of the Caspian energy sector. (2013, January). BP Group.

- 2014 In review. Global primary energy consumption decelerated sharply in 2014, even though global economic growth was similar to 2013. (2014). Statistical Review of World Energy 2015. BP Group. Retrieved December 25, Retrieved January 25, 2013, from http://www.bp.com/content/dam/bp-country/ru_ru/folder/2030_Booklet_rus.pdf.

- World Energy Outlook 2015 Special Report. (2015, June 15). International Energy Agency. Retrieved June16, 2015, from http://www.iea.org/bookshop/477-World_Energy_Outlook_2014.

- The balance of energy of the Russian Federation, 2013. Federal State Statistics Service. Russian Federation

- Energy. Regulatory and methodological support. The main provisions, 2012. GOST 31607-2012. Russian Federation.

- Method for determining energy consumption in the production of goods and provision of services in technological energy systems. General Provisions (p. 6.2.” The nature of the possible energy losses and direction of their reduction to the product life cycle and execution services “), 2001. GOST R 51750-2001. Russian Federation.

- Energy balance of the industrial enterprise. The main provisions, 1988. GOST 27322-87. Russian Federation.

- Federal Law of the Russian Federation # 261. (2009, November 23). On energy saving and energy efficiency and on Amendments to Certain Legislative Acts of the Russian Federation.

- Meshcheryakovа, T. C. (2015). Development of the organizational-economic mechanism of energy efficiency in the enterprise. Economics and Entrepreneurship, 1.

- ICF International National Association of Energy Services Companies. (October, 2007). Introduction to Energy Performance Contracting. Retrieved November, 2007, from http://www.energystar.gov/ia/partners/spp_res/Introduction_to_Performance_Contracting.pdf.

- Energy management system. Requirements with guidance for use, 2012. GOST R ISO 50001-2012. Russian Federation.

- Amendments to the Federal Law “On Concession Agreements and some legislative acts of the Russian Federation #152”. (2010, July 2). On Concession Agreements. Russian Federation. 2014, from http://www.bp.com/en/global/corporate/about-bp/energy-economics/statistical-review-of-world-energy/2014-in-review.html.

- Limitovsky, M.A. (2004). Investment projects and real options in emerging markets. Moscow, М: Business.

- Lawrence G. McMillan. (1986). Оptions as a strategic investment. A Comprehensive Analysis of Listed Option Strategies (2nd ed.). New York, NY: Institute of Finance.

- Institute for Systems Analysis, Central Economic Mathematical Institute, et al. (2004). Guidelines on the assessment of investment projects. Moscow, М: Institute for Systems Analysis.

This work is licensed under a Creative Commons Attribution 4.0 International License.