How to Cite | Publication History | PlumX Article Matrix

Bioconversion of Municipal Solid Wastes for Bioethanol Production

J. Patra1, A. Basu2, A. Mishra3 and N. K. Dhal2

1Department Biotechnology, North Orissa University Baripada, India.

2Environment and Sustainability Department, CSIR-IMMT, Bhubaneswar, Odisha, India.

3Department Biotechnology Vinoba BhaveUniversity, Hazaribagh, Jharkhand, India.

Corresponding Author E-mail: jyoshnamayeepatra30@gmail.com

DOI : http://dx.doi.org/10.13005/bbra/2554

ABSTRACT: The use of dilute acid (H2SO4, 3%) and alkali (NaOH, 3%) pretreatment methods has some potential how ever to date, these methods effectively increase ethanol production of municipal solid waste (MSW). Enzymatic hydrolysis was carried out with Aspergillus niger, Aspergillus fumigatus and Trichoderma reesei. Finally, the fermentation was done by sugar three ethanologenic yeasts, Saccharomyces cerevisiae, pichia stipitis, canida shehatae for bioethanol production.The highest ethanol yield (22.32%) v/v. was obtained with a pre-hydrolysis treatment consisting of NaOH at 3% concentration, followed by Pichia stipitis and enzymatic hydrolysis with Aspergillus niger. Pre-hydrolysis treatment consisted Enzymatic hydrolysis was carried out with Alkali pretreated wastes yield more sugar as compared to acid treatment using produced more ethanol than others at each time point. The experimental results observed that 80% of the cellulose converted to glucose from the waste which can be easily fermented to production. of ethanol. The ability focus on related environmental issues, such as sustainable waste management, climate change, land use and biodiversity, are discussed.

KEYWORDS: Bioethanol; Biomass; Municipal solid waste (MSW); Microbial strain; sustainable waste management

Download this article as:| Copy the following to cite this article: Patra J, Basu A, Mishra A, Dhal N. K. Bioconversion of Municipal Solid Wastes for Bioethanol Production. Biosci Biotech Res Asia 2017;14(3). |

| Copy the following to cite this URL: Patra J, Basu A, Mishra A, Dhal N. K. Bioconversion of Municipal Solid Wastes for Bioethanol Production. Biosci Biotech Res Asia 2017;14(3). Available from: https://www.biotech-asia.org/?p=27146 |

Introduction

As perturbed about grows of climate change, there is more interest regarding energy production from waste materials (i.e., bioethanol from waste) as a Method which reduce GHG emissions, as well as of Providing a fuel source for the transport industry. Consequently, the recent RED amendment imposes a cap on the use of food crops and clearly enhance the waste and residue feedstocks are used.1 Nonetheless, ability of environmental risks which clearly related to bioethanol production from wastes and residues have been raised in the literature.2-9 Regarding GHG emissions, literature is still scarce.2-6 Municipal Solid Waste (MSW) is one of the waste materials acts as a viable source for bioethanol production in both the RED and the literature. The replacement of biomass with Municipal Solid Waste can bring in environmental advantages, particularly in waste management.1 Bioethanol production depends on three consecutive stages: pre-treatment, hydrolysis, and fermentation. Forestry and municipal solid waste reduces are abundant, renewable energy sources. When hydrolyzed, these enzymes materials release carbohydrates (D-glucose, D-galactose, D-xylose, D-mannose, D-Fructose, L- arabinose) and several compounds derived from sugar and lignin estimation.2 The presented experimental work indicated that various municipal solid waste fraction has vast potential for the production of sugar that eventually can be used for producing bio- ethanol. MSW also analysis favorably with forestry waste, agricultural waste, other waste and residue feedstocks since it is accessible throughout the year, it is concentrated(supply locations), and it is complimentary or even a direct source of proceeds due to the negative cost paid for its wates, e.g. landfill gate fee10 MSW is a heterogeneous mixture of different waste materials, such as food scraps, plastics, paper and cardboard, wood, textiles and inert materials.The configuration of MSW be dependent on the waste management system, feeding habits and economic development of the region considered.7

Municipal solid waste comprises of waste generated from residential, commercial and institutional. Ethanol use as a transportation fuel has long been a near term additive and substitute for gasoline. Anaerobic digestion (AD) is often considered one of the more economically, and environmentally sound technologies currently used in the treatment of MSW11 As researchers12 pointed out that the most appropriate pre-treatment method depends upon the type of biomass used, it is unclear whether current pre-treatment technologies can be used for MSW. For these reasons, it is clear that further research is needed in these areas to develop an effective and low-cost MSW-based bioconversion technique. Mechanical pretreatment has been successful in reducing particle size and disrupting the crystalline structure of LMSW.13 However, these pretreatment Method often require significant energy inputs, and therefore may not be the most economically and environmentally sound technologies14-15 Biological pretreatment, which is a safe and environmentally friendly method of using microbes, offers same conceptually important advantages such as low chemical energy used14 The sustainable development and economic growth pose a big challenge to the environment such as greenhouse gas emissions, resource consumption, and massive waste generation.

Materials and Methods

The municipal solid waste (MSW) was obtained by mixing official paper waste, newspaper, and cardboard, all of which were collected from a trash collection point at CSIR- Institute of Minerals and Material Technology of Bhubaneswar, AcharyaVihar, Bhubaneswar, India. The mass-mixing ratio of paper, cardboard and kitchen waste was 1:1:1. All paper waste was first cut into 20 _ 20 mm squares, and oven dried at 800C for 48 h and stored in air tight container at room temperate till further use.

Pre-Hydrolysis Treatment

The biomass was pretreated with using 3% of 200ml of dilute sulfuric and sodium hydroxide autoclaved it at 121 lb inch2 15psi for 20 minutes. After autoclaving the sample was filtered and dried at 60°C for overnight. The time and temperature of pretreatment are strongly dependent on the concentration of the used acid and alkali on the wanted outcomes.

Enzymatic Hydrolysis

Enzymatic hydrolysis of the pre-hydrolyzed substrate was carried out within the study temperature range in vials (50 ml) placed in an orbital agitator at 120 rpm for 72 h. The liquor pH was adjusted using 0.1 M citrate acid-sodium citrate buffer. Enzymes, Then 1ml of enzyme extract of Aspergillus niger, Aspergillus fumigatus, and Trichoderma reesei was added to the sample, and then the sample was kept on shaker incubator for 72nd hours, followed by sugar estimation. The quantities of reducing sugars produced by the enzy-matic hydrolysis was calculated by dinitrosalicylic acid (DNS) method20 The sample (1.0 mL) was added with 3 mL of DNSA reagent. All tubes placed on boiling water bath for 5 min for heating, after cooling at room temperature the absorbance was measured at 640 nm.

Fermentation

The hydrolysate (produced after enzymatic saccharification) was inoculated with one ml of yeast extract Saccharamycescerevisiae, pichiastipitis, canidashehatae was inoculated in both control and treated sample at 28°C for 72 hours on a shaker at 120rpm. Ethanol was calculated using UV-visible spectrophotometer (Systonics-2203) at 600nm from the distilled sample by adding dichromate reagent. More information about the set-up can be found elsewhere.16

SEM-Analysis

The general study regulated overall analysis determined both untreated and pretreated dehydrated samples were air dried at 600 C for overnight. For SEM, samples were ascended in SEM stubs and coated with gold, following the standard protocol. The mounted specimens were analyzed with a JEOL JSM 6510 (Jeol Ltd, Tokyo, Japan) SEM.

Results and Discussion

Percentage of chemical composition of lignocellulosic Municipal solid waste after pretreatment:

Bioethanol production from Municipal solid waste using both acid pretreatment and alkali pretreatment was studied in this work. Cellulose, hemicellulose, and lignin content of both acid and alkali pretreatment results shown in Fig 1.

|

Figure 1: Percentage of cellulose, hemicellulose, lignin after pretreatment |

The results showed that the MSW contained significant levels of cellulose, hemicellulose, and lignin. The cellulose content of the MSW (63.4 g/56.9) was similar to that reported by17-18 which were 28.8 and 25.6 g/100 g, respectively. The hemicellulose content (23.1 g/21.2 g) was again similar to the 11.9 g/100 g reported by Jones et al. However, these are higher than several other values for example 5.14, 5.8 and 6.6 g/100 g as reported by19 respectively. Lignin content of our MSW (14.5 g/9.9) was close to the values reported by.18-19 these being 12.67; 15.7 and 15.2 g/100 g, respectively.

The reducing sugar yields from the MSW using Acid and Alkali treatment method are shown in Fig 2 and 3.

|

Figure 2: Acid pretreatment of Municipal solid wastes |

|

Figure 3: Alkali pretreatment of Municipal solid wastes |

The hydrolysis was done with three different fungus like Aspergillus niger. Aspergillus fumigatus and Trichoderma reesei. and mixed all microbes respectively at the different period in acid and alkali pretreatment. Determined sugar at 0, 24, 48 and 72 h. This resulted shown at Fig-2&3.. Aspergillus niger. Aspergillus fumigatus given better results in both acid and alkali pretreatment of than others. As observed in Fig 2& 3, the relative low glucose yield from MSW at the 0th hour to 72nd hour can be explained because of the highest crystallinity structures which are difficult to be broken down by the enzyme.

Percentage of Ethanol Yield After Fermentation

Ethanol Yield by Samples (Using Acid Pretreatment)

Due to develop cost of fermentation process for bioethanol, cellulase production is one of the important steps for hydrolysis of the lignocellulosic materials. Several different strains have been advanced since then to higher the production of cellulase from the fungal strain QM6a21 Finally, the fermentation was done by three ethanologenic yeasts, Saccharamyces cerevisiae, pichia stipitis, canida shehatae were applied to ferment sugar solutions. Ethanol yields are shown in Fig.4 at (2.9, 11.7, 10.4 8.6 %), (19.37, 12.5, 13.58, 11.84%) and (8.99, 8.92, 7.76, 8.06%) v/v respectiviley. Pichia stipitis using Aspergillus niger produced more ethanol than others at each time point.

|

Figure 4: Ethanol estimation of Acid treatment of Municipal solid wastes |

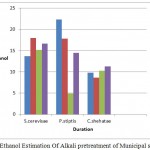

Ethanol yield by samples (Using Alkali pretreatment)

|

Figure 5: Ethanol Estimation of Alkali pretreatment of Municipal solid wastes |

After hydrolysis was done with three different fungus like Aspergillusniger.Aspergillusfumigatus and Trichodermareesei and mixed culture. Finally, the fermentation was done by sugar three ethanologenic yeasts, Saccharamycescerevisiae, pichiastipitis, canidashehatae were applied to ferment sugar solutions. Ethanol yields for different fermented yeast are shown in Fig.5 at (13.73, 17.98, 15.15, 16.66 %), (22.32, 17.85, 4.93, 14.45) and (9.84, 8.62, 10.28, 11.31) v/v. pichiastipitis usingAspergillusniger produced more ethanol than others at each time point.

|

Figure 6: SEM Analysis of Municipal solid wastes |

SEM Analysis

Scanning electron microscope images also confirm that both acid and alkali treatment is very effective in disrupting the plant cell wall structure. SEM images show that very little damage to cell walls compared to the untreated sample, while acid and alkali treatment has destroyed most of the cell walls and exposed cellulose fibers both untreated and pretreated sample of MSW. The morphological changes that take place during pretreatment were analyzed, and it is found that the inhibitory hydrocarbons were separate; crack development on the lignocellulosic fiber and increase in porosity could be seen resulting in enhanced exposure of cellulosic material for effective bioconversion.

Conclusion

Alkali pre-treatment was given better result in comparison to acid pre-treatment as it is non-toxic as well as cost effective. After pretreatment, the hydrolysis was done by different fungus A.niger, A.fumigatus, T.reesei and mixed culture followed by the fermentation was done by normal Saccharamyce scerevisiae. After fermentation, distillation was done and percentage of ethanol was calculated. Bioconversion of municipal solid wastes to bio-ethanol production has its economic and environmental advantages compared with the traditional process with municipal solid wastes product. It can be used as an alternative sustainable wastes management option. Sustainable wastes management needs to involve the different type of waste management methods in order to minimize the waste produced, and maximize and to meet the needs of environmentally, economically and socially sustainable.

References

- European Commission EUR 27215 EN e Joint Research Centre e Institute for Energy and Transport Title: Solid and gaseous bioenergy pathways: input values and GHG emissions Author(s): Jacopo Giuntoli, Alessandro Agostini, Robert Edwards, Luisa Marelli Luxembourg: Publications Office of the European Union http://iet.jrc.ec.europa.eu/bf-ca/sites/bf-ca/files/files/documents/eur26696_online_final_v3.pdfe. 2015; 248.

- Stichnothe A. A. Bioethanol from waste life cycle estimation of the greenhouse gas saving potential. Resour. Conserv. Recycl. 2009;53(11):624-630.

CrossRef - Onel A. M., Niziolek M. M. F., Hasan C. A. F. Municipal solid waste to liquid transportation fuels – Part I: mathematical modeling of a municipal solid waste gasifier. Comput. Chem. Eng. 201;71:636-647.

CrossRef - Niziolek M., Onel O., Hasan M. M. F.,Floudas C. A. Municipal solid waste to liquid transportation fuels – Part II: process synthesis and global optimization strategies. . Comput. Chem. Eng. 2015;74:184-203.

CrossRef - Wang R., Templer R. J. Murphy Environmental sustainability of bioethanol production from waste papers sensitivity to the system boundary. Energy Environ. Sci. 2012;5(8):8281-8293.

CrossRef - Schmitt R., Bura R.,Gustafson J.,Cooper A. V. Converting lignocellulosic solid waste into ethanol for the State of Washington: an investigation of treatment technologies and environmental impacts. Bioresour. Technol. 2012;104:400-409.

CrossRef - Rada C. Energy from municipal solid waste. WIT Trans. Ecol. Environ. 2014;190(2):945-958.

CrossRef - Samer M. GHG emission from livestock manure and its mitigation strategies. Clim. Change Impact Livest. Mitig. 2015;321-346.

CrossRef - Giuntoli S., Caserini L., Marelli D., Baxter A. A. Domestic heatingfrom forest logging residues environmental risks and benefits. J. Clean. Prod. 2015;99:206-216.

CrossRef - Arena F., Gregorio D., De G., Troia A. S. A techno-economic evaluation of a small-scale fluidized bed gasifier for solid recovered fuel. Fuel Process Technol. 2015;131:69-77.

CrossRef - Ham K and T. J. (Booker, ) Decomposition of solid waste in test lysimeters. Journal of Environmental Engineering. 1982;108:1147-1170.

- Pommier A., Llamas M and Lefebvre X. Analysis of the outcome of shreddingpretreatment on the anaerobic biodegradability of paper and cardboard materials. Bioresour. Technol. 2010;101:463–468.

CrossRef - Binod R., Sindhu R. R., Singhania S., Vikram L., Devi S., Nagalakshmi N., Kurien R. K. S and Pandey A. Bioethanol production from rice straw an overview. Bioresour Technol. 2010;101:4767–4774.

CrossRef - Sun and Cheng J. Hydrolysis of lignocellulosic materials for ethanol production a review. Bioresour. Technol 2002;83:1–11.

CrossRef - Infantes A., Del G., Campo J. V and Fernández F. J. Influence of pH, temperature and volatile fatty acids on hydrogen production by acidogenic fermentation. International Journal of Hydrogen Energy. 2011;36(24): 15595-15601.

CrossRef - Prasad A. S and Joshi H. C. Ethanol as an alternative fuel from agricultural, industrial and urban residues. Resources, Conservation & Recycling. 2007;50:1-39.

CrossRef - Barlaz A., Ham R. K and Schaefer D. M. Methane production from municipal refuse: a review of enhancement techniques and microbial dynamics. Crit. Rev. Environ. Control. 1990;19-31:557–84170.

- Jones R.V., Taylor D. P and Dixon N. Shear strength of waste and its use in landfill stability analysis. In: Yong, R. N., Thomas H. R. (Eds.) Proceedings Geo environmental Engineering Conference. Thomas Telford. 1997; 343–35.

- Price A., Barlaz M. A and Hater G. R. Nitrogen management in bioreactor landfills. Waste Management. 2003;23:675–688.

CrossRef - Miller L. Use of dinitrosalycilic acid reagent fordetermination of reducing sugar. Anal Chem. 1959;3:426–428.

CrossRef - Mandels M., Sternberg D. Recent advances in cellulasetechnology. J Ferment Technol. 1976;54:267–286.

This work is licensed under a Creative Commons Attribution 4.0 International License.