How to Cite | Publication History | PlumX Article Matrix

Keratinolytic Enzymes for Cleaning Edible Bird’s Nest

Sri Rahayu1,2, Maggy T. Suhartono2, Wardhana Suryapratama1 and Muhamad Bata1

1Faculty of Animal Science, Jenderal Soedirman University,Purwokerto-Indonesia.

2Faculty of Agricultural Technology, Bogor Agricultural University, Bogor-Indonesia.

Corresponding Author E-mail: sirahayu27@gmail.com

DOI : http://dx.doi.org/10.13005/bbra/2533

ABSTRACT: Edible bird’s nest (EBN) as a kind of functional food has high economic value depending on the quality such as color and hygiene. The purpose of this research was to find optimum condition for application of keratinolytic enzymes Bacillus sp. MTS in cleaning EBN. Activating agents for both enzymes were cation divalents, EDTA, reducing agents, organic solutions, and antibacterial agents. Additives compound that able to increase keratinase activity were used to make cleaning solution and its tested on EBN and human hair. Alcoholic solutions (25% ethanol, 25% methanol, 25% glycerol), and some divalent metallic ions(Ca2+, Mg2+, Mn2+, Zn2+)were able to increase keratinase while disulfide reductase was solely activated by 0.05 mM EDTA. The activity of both enzymes was inhibited by Na Cland Na-azide. The activity of keratinase of Bacillus sp. MTS in cleaning solution formulated in this research was 2-3 fold as much as control (crude extract) in human hair substrates. Gliserol and cations divalent increasing 2-3 fold keratinase activity in cleaning solution. The solution was successfully apllied to cleaning EBN with weight loss 2.3-2.5% approximately.

KEYWORDS: Bacillus; cleaning; edible bird’s nest keratinase;

Download this article as:| Copy the following to cite this article: Rahayu S, Suhartono M. T, Suryapratama W, Bata M. Keratinolytic Enzymes For Cleaning Edible Bird’s Nest. Biosci Biotech Res Asia 2017;14(3). |

| Copy the following to cite this URL: Rahayu S, Suhartono M. T, Suryapratama W, Bata M. Keratinolytic Enzymes For Cleaning Edible Bird’s Nest. Biosci Biotech Res Asia 2017;14(3). Available from: https://www.biotech-asia.org/?p=27046 |

Introduction

Edible bird’s nest (EBN) is one of the mostexpensive animal products, its a saliva produced bytwo specific swiftlets, namely Aerodramus fuciphagus (white-nest) and Aerodramus maximus (black-nest).1 EBN is a functional food containing high quality nutrients such as proteinx, carbohydrate, iron, inorganic salts and fiber.2,3,4 EBN also serves medical function as anti aging, anticancer, immunity enhancing agent, inhibiting influenza virus infection and improving respiratory and digestive problems.5,6 EBN is a good economic value namely 20 million and 10 million rupiahs per kg for white nest and red nest, respectively depending on the quality.7 The primary factor ofEBN quality is color and hygiene, therefore the whiter and cleaner EBN, the higher isthe price.

The steps in cleaning EBN is a tedious work for being meticulous and perseverant to obtain high quality product. Koon and Cranbrook7 informed that it takes eight hours to have someone clean 10 nests through soaking process in cleaning solution. The solution however cannot wash away the bird’s feather that is stuck inside the nest; therefore, it takes a time-consuming manual process to singly discard the feathers using pincers.

The commonly used cleaning solution among the farmers/collectors is chemical-based solution containing hydrogen peroxide (H2O2) known as whitening/bleaching agent. Replacing the chemicals in cleaning process with natural body-safe bleaching namely protease enzyme is one of the solution.Several alkaline proteases have been purified and characterized from many Bacillus strains.8,9,10,11 We had isolated a feather degrading bacteria and its refered to Bacillus sp. MTS. This bacillus strain was aerobic mesophillic bacteria, its very effective in degradation of whole chicken feather and this appeared to be related to activity of the extracellular keratinase and disulfide reductase enzymes. The crude extract from the isolate has been showed capable of degrading whole chicken feathers, silk, cocoon, hair and fish scales.12 The purified enzymes of Bacillus sp. MTS worked optimally at alkaline pHs, for keratinase at pH8–12, and for disulfide reductase at pH8–10. Optimum temperature for the extra cellular keratinase was within 40–700C, while that for disulfide reductase was 350C13. We attempted to apply this enzymes to solve the problem contaminant feather that is stuck inedible bird’s nest.

In the present study, we report the effect of several compound in a cleaning formula containing keratinolytic enzymes and testing the formula toclean EBN. This cleaning solution is expect to be environment-friendly and the enzymatic hydrolysis can shorten the cleaning process of EBN.

Materials and Methods

Growth Conditions and Enzymes Production

The aerobic mesophilic Bacillus sp. MTS was used in these experiments. Its screened and isolated from Tangkuban Perahu crater West Java-Indonesia. The agar medium for culture maintenance pursuant to Macedoet al.14 with few modification viz. contained 0.6% crushed dried feather (powder). For enzyme production, 250 ml medium containing several inorganic salts with1.0% chicken feather powder was used as substrate,15 pH was adjusted to7.5. Incubation was carried out in a1 l flaskat 370C 100 rpm for 48 h. After incubation the culture was strained and centrifugedat 4000 g40C for 10 min to harvest the extra cellular enzymes.

Protein and Enzymes Assay

Protein concentration was measured at 595 nm in accordance with Bradford, using bovine serum albumin as the standard protein.16 Keratinase activity was measured according to Walter17 using 1% feather powderin Tris/HCl(50mM,pH8.0) as substrate and absorbanceof the samples were readat 660nm. Atyrosin standardcurve was made for quantification. One unit of enzyme activity was assigned as the amount of enzyme whichliberate1 mmoltyrosinein one min.

Disulfide reductase activity was assayed asdescribedby Serrano etal.18 with a few modifications. Enzyme was mixed with 500 ml of Tris / HCl buffer (0.13m M, pH9.0) containing 0.05m M oxidized glutathione (GSSH) and 0.05 m MEDTAthen incubated at room temperature for 10 min. After centrifuged at 1000 g40C for 10 min, the reaction product was detected by addition of DTNB (dithiobis-nitrobenzoicacids). Absorbance was measured at 405 nm after 2 min of stable color development.13

Effect of Additivescompound

Additives compound tested were divalent cations (Mg++, Zn++, Ca++, Mg++), EDTA (ethylenediaminetetraacetic acid), reducing agentsviz. dithiothreitol(DTT) and β-mercaptoethanol (BMT). Organic solvents tested were ethanol, methanol, glycerol and tween 20 and antibacterial agents namely NaCl and Na-azide. Various additives and concentration were tested and observed for the effect on keratinase and reductase activity. An concentration to increase enzyme activity was chosen to formulate with the crude extract of Bacillus sp. MTS as the cleaning solution formula.

Cleaning Formulation

The detergent formulations were prepared by mixing a 1 liter crude extract of Bacillus sp. MTS with 2% (v/v) glycerol, 2 mM CaCl2, 2 mM MgCl2, 2 mM ZnCl2 and 5 mM MnCl2, the experiments were donewith 0.16 U/mg.

Cleaning Test

Cleaning formula was testedon human hair and its was performed at 50oC for 0, 20, 40, 60 and 90 minutes. Hydrolyzed keratin products were then measured using a spectrophotometer to obtained the exact time and temperature to react cleaning solution with substrate.The solution also tested for cleaning whole EBN.The first step,EBN was cleaned withaquadest and then 25% ethanol. Hereafter, it’s dipped in cleaning solution, then left at room temperature for 10 minutes and incubated at50oC for 20minutes. After repealing the feather, EBN wasdried on 40oC for 40hours.EBN was weighed before and after cleaning processes.

Results and Discussion

Effect of Several compound to Keratinase and Disulfide Reductase Activity

Proteases have extensive applications in a range of industrial products and processes including detergent, food, pharmaceuticals, tannery, waste treatments, resolution ofamino acid mixtures, silk and silver extractionfrom used X-ray films.19 Keratinase is known as keratinolytic protease capable of binding and hydrolyzing solid substrate like feather or hair. This capability is important since detergent enzyme is required to react with protein substrate (keratin) sticking on fabric such as collar.20

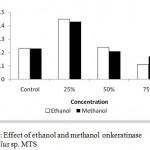

Activiting keratinolytic enzymes in crude extract of Bacillus sp. MTS was increased by 25% (v/v) ethanol and methanol, the increased activity was 49% and 46% for ethanol and methanol, respectively, higher than that of control (Figure 1). Skrzydlewska et al.21 reported that ethanol increased protease cytosol (cathepsin) higher than ethanol. Methanol increased cathepsin activity C and E as much as 28% and 34%, respectively, while ethanol cathepsin C and B was as much as 45% and 42%, respectively.Ethanol and methanol are two additives extensively used as cleaning solution. Ethanol is also used as anti-microbial agent to kill or inhibit the growth of disease and odor-stimulating microbe. Economy and toxicity consideration has made ethanol chosen in cleaning solution of edible bird’s nest.

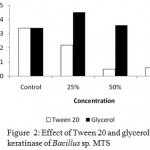

Glycerol concentration of 25% can increase keratinase activity as much as 24% higher than that of control, while Tween 20 inhibited activity ofkeratinaseBacillus sp. MTS (Figure 2).Protein stability has important role in keeping biological function of the protein for example during protein design, refolding and storage. Glycerol has long been used to protect enzyme activity and native protein structure against denaturation. Glycerol as reported by Menget al.22 is able to increase structure of native creatin kinase. Glycerol enhanced the keratinase activity at concentration of 25% whereas Tween 20 inhibited its activity. Tween 20 is a nonionic detergent, used extensively for solubilization of membrane proteins and their biochemical characterization. Fig.1B showed that Tween-20 was ineffective for this purpose, therefore it could not be used as additive for cleaning solution.

|

Figure 1: Effect of ethanol and methanol onkeratinase of Bacillus sp. MTS

|

|

Figure 2: Effect of Tween 20 and glycerol on keratinase of Bacillus sp. MTS

|

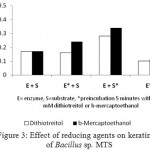

Reducing agents viz dithiotreitol (DTT) and and β-mercaptoethanol (BMT) significantly affect keratinase activity. When the enzyme reacted with reducing agent (E*), hydrolyzed product drastically decreased, indicating enzyme damage.However, when substrate (chicken feather) was pre-incubated with reducing agent before being reacted with enzyme (E+S*), hydrolyzed product increased (Figure 3).DTT and BMT significantly affect keratinase activity. When the enzyme reacted with reducing agent, hydrolyzed product drastically decreased, indicating enzyme damage. However, when substrate (chicken feather) was pre-incubated with reducing agent before being reacted with enzyme, hydrolyzed product increased (Figure 3). Several researches reported factors of disulfide bond reduction in the activity of keratin-user microorganism. Bacillus sp.MTS produces keratinase and disulfide reductase, and the reaction of both enzymes results in drastic increase of keratinolytic activity (more than 20 fold) compared to sole keratinase .13 It showed that keratinase affinity is higher when keratine substrate has priorly been reduced by either reducing agent or reductase disulfide enzyme.

|

Figure 3: Effect of reducing agents on keratinase of Bacillus sp. MTS

|

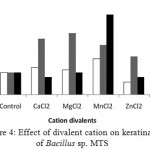

For maximum activity, protease alkali needs cation divalent such as Ca2+, Mg2+ and Mn2+ or the combined cations. Cation is also needed to increase thermal stability of the alkaline protease of Bacillus. Cation protects enzyme from thermal denaturation effect and importantly maintain active enzyme conformation at high temperature.19 Some cationsincrease the keratinase activity of Bacillus sp. MTS at different concentration. At 2 m Mconcentration Ca2+, Mg2+ and Zn2+cation increases keratinase activity as much as 266%, 266% and 166%, respectively. While Mn2+ at 5 m M concentration increases keratinase activity to 360%, higher than that of control (Figure 4).Rahayu et al.12 informed that Bacillus sp. MTS produced sixth proteases, their molecular weights are 17, 25, 32, 53, 96 and > 97kD. Keratinase Bacillus sp.MTS activated by Ca2+, Mg2+ and Zn2+(Fig.4), this result is in line with Bernard23 that >97 kD a and 96 kD a Bacillus sp. MTS protease were activated by Mg2+ and Mn2+ and inhibited by 2 mM EDTA. Its indicated that both protease belong to metal protease.

|

Figure 4: Effect of divalent cation on keratinase of Bacillus sp. MTS

|

The effect of additives to Bacillus sp. MTS reductase activity showed that reductase enzyme was obstructed by various tested additives. Activity increase was observed when reductase was reacted with 0.05 m MEDTA (Table 1). Reductase enzyme (E.C. 1.6.4) is active enzyme that catalyzes reduction of disulfide bonds and both are included in oxido reductase. The active site of thiol-disulfide oxido reductase bears Cys-Xxx-Yyy-Cystmotifs and both residual cysteine contribute to oxidized disulfide cycle and reduced thiol (redox reactions).24 EDTA as chelate agent made reductase active site work optimally in hydrolyzing disulfide bonds in keratin structure, resulting in 10 fold increase of hydrolysis product.Inorganic ions could relate to protein side chain or interact with the active site in which these interactions might not affect the structure but facilitate or complicate substrate molecule to be or relate with enzyme active site.25 The interrupted interaction between substrate and enzyme active site caused the catalytic activity of enzymedecrease. The presence of salt usually affect the conformation, folding, stability and activities of enzymes. Some enzymes are affected by monovalent cations, other and in most cases are affected by divalent cations. Monovalent cation and monovalent anions may neutrilize protein charges, and that may change protein structure with, no effect or decreasing or increasing enzyme activity. In this case the salt (NaCl) might be unfavorable to the enzyme conformation and enzyme substrate interaction.13

Tabel 1: Effect of several compound on reductase activity of Bacillus sp. MTS

| Compound | Concentration | Activity (%) |

| EDTA | 0 mM | 100 |

| 0.05 mM | 1025 | |

| 0.25 mM | 0 | |

| 0.5 mM | 0 | |

| Alcohol | ||

| Ethanol | 25% | 25 |

| Methanol | 25% | 0 |

| Glycerol | 25% | 95 |

| Cations | ||

| NaCl | 0% | 100 |

| 5% | 30 | |

| 10% | 0 | |

| 20% | 0 | |

| ZnCl2 | 0 mM | 100 |

| 1 mM | 58 | |

| 2 mM | 20 | |

| 3 mM | 8 | |

| MgCl2 | 0 mM | 100 |

| 1 mM | 38 | |

| 2 mM | 0 | |

| 3 mM | 0 | |

| CaCl2 | 0 mM | 100 |

| 1 mM | 42 | |

| 2 mM | 16 | |

| 3 mM | 0 |

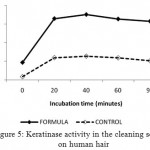

Based on the test on various additives towards keratinase activity and reductase, one formula of cleaning solution for edible bird’s nest was composed. The formula was then tested on human hair at 50oC at various incubation periods. Keratinase in the formula was generally 2-3 times higher than that of control (Figure 6).

Effect of Several compound to Activity of Keratinasein Cleaning Solution

Bacillus sp. MTS produces six protease molecules in its cell-free filtrates, two of which are kreatinase. Various types of keratinase in Bacillus sp. MTS enable the bacteria to degrade keratin substrate such as chicken feather, human hair, cocoon, silk, fish scale and horn.12 Edible bird’s nest is mainly composed of glycoprotein with carbohydrate components of 9% sialic acid, 7.2% galactosamine, 5.3% glucosamine, 16.9% galactose and 0.7% fructose. Protein of edible bird’s nest is mainly composed of serine amino acid, threonine, aspartic acid glutamate acid, proline and valine1. Marcone2 reported that edible bird’s nest contained fat (0.14–1.28%), ash (2.1%), carbohydrate (25.62–27.26%) and protein (62–63%). Furthermore, 10% feather was found stuck in the nest. Protein substrate and keratin in edible bird’s nest enabled enzyme in cleaning solution to function well and produce hydrolysis.

|

Figure 5: Keratinase activity in the cleaning solution on human hair

|

Keratinase activity of Bacillus sp. MTS in human hair was higher (Figure 6). Cysteine content in keratin was approximately 8% and absent in other proteins, while cysteine content in human hair was double of that in chicken feather (15.6-21.2% vs 7.05-12.2%).26 Keratin structure became very solid due to disulfide bridge between two amino acids (cysteine). Keratinase and reductase disulfide of Bacillus sp. MTS was observed to perform specific and synergic hydrolysis in peptide and disulfide bonds of human hair. Specificity of the two enzymes resulted in higher substrate hydrolysis on human hair than on edible bird’s nest (data not showed). However, it resulted in beneficial effect as cleaning solution because low keratinase activity would prevent edible bird’s nest from protease enzyme breakdown.

|

Figure 6: Edible bird’s nest unprocessed (left) and processed (right)

|

Cleaning edible bird’s nest (EBN) need several steps before its cleaned by enzymes viz. in dip several times using aquadest, 25% ethanol and enzyme solution. Aquadest and 25% ethanol removing the dust and faeces on the EBN, it’s also preparing EBN for enzyme activity. Then it’s incubated at room temperature for 10 minutes and 50oC for 20 minutes after immertion in enzyme solution. These incubation processes will provide opportunities the enzymes for loosening the bond between feather and EBN. The next stage was taken away the bird’s feather that is stuck inside the nest using feather Plucker. All steps effectively cleaning EBN, it’s appeared white and neat (figure 6). This cleaning process demonstrated that keratinolytic enzymes in solution capabilities to clean EBN, the weight loss of EBN was 2.3-2.5% approximately (data not showed).

Conclusions

Keratinase in crude extract of Bacillus sp. MTS was activated by 25% ethanol, 25% methanol, 25% glycerol, and metal Ca2+,, Mg2+,, Mn2+,, Zn2+ and it was inhibited by NaCl and Na-azide. While reductase disulfide enzyme was solely activated by 0.05 mM EDTA.

Keratinase activity of Bacillus sp. MTS in cleaning solution formula increased 2-3 fold compared to that of control (crude extract) in human hair substrates. The solution was successfully to clean EBN with weight loss 2.3-2.5% approximately.

Acknowledgement

This research was financially supported by Ministry of Research and Technology Indonesia pass through Incentive Research Si Nas programme. Thanks to Ika Malikah, Anastasia and Megahwati Effendy for their practical support.

Conflict of Interest

The authors have NO affiliations with or involvement in any organization or entity with any financial interest or non-financial interest (such as personal or professional relationships, affiliations, knowledge or beliefs) in the subject matter or materials discussed in this manuscript.

References

- Goh D. L. M., Chua K. Y., Chew F. T., Liang R. C. M. Y., Seow T. K.,Ou K. L. , Yi F. C., Lee B. W. Immunochemical characterization of edible bird’s nest allergens. Allergy Clin. Immunol. 2001;107(6):1082–1088.

CrossRef - Marcone M. F. Characterization of the edible bird’s nest the ‘Caviar of the East. Food Res. Int. 2005;38(10):1125–1134.

CrossRef - Hamzah Z., Ibrahim N. H., Jaafar M. N., Lee B. B., Hashim O., Hussin K. Nutritional properties of edible bird nest. Asian Sci. Res. 2013;3(6):600–607.

- Huda M. Z., Zuki A. B. Z.,Azhar K.,Goh Y. M., Suhaimi H., Hazmi A. J. A.,Zairi M. S. Proximate elemental and fatty acid analysis of pre-processed edible birds’ nest (Aerodramusfuciphagus)a comparison between regions and type of nest. Food.Technol. 2008;6(1):39–44.

- Wu Y., Chen Y., Wang B., Bai L., Han W. R. , Ge Y., Yuan F. Application of SYBR green PCR and 2DGE methods to authenticate edible bird’s nest food. Food Res. Int. 2010;43(8):2020–2026.

CrossRef - Ma F and Liu D. Sketch of the edible bird’s nest and its important bio activities. Food Res. Int. 2012;48(2):559–567.

CrossRef - Koon L. C and Cranbrook E. Swiftlets of Borneo–Builders of edible nests. 2002;1–171. Sabah, Malaysia: Natural History Publication (Borneo) S .D. N., B. H. D

- Bhaskar N., Sudeepa E. S., Rashmi H. N and Sevi T. A. Partial purification and characterization of protease of Bacillus proteolyticus CFR 3001 isolated from fish processing waste and its antibacterial activities. Biores. Technol. 2007;98(14):2758-2764.

CrossRef - Doddapaneni K. K., Tatineni R.,Vellanki R. N.,Gandu B., Panyaia N. R., Chakali B ,Mangamoori L. N. Purification and characterization of two novel extracellular alkaline proteases from Serratiarubidaea. Process Biochem. 2007; 42(8):1229-1236.

CrossRef - Padmapriya B., Rajeswari T., Nandita R., Raj F. Production and purification of alkaline serine protease from marine Bacillus species and its application in detergent industry. European J. of Applied Sci. 2012;4(1):21-26.

- Nadeem M., Javed I. Q., Quratulain S., Muhammad G. Purification and characterization of an alkaline protease from Bacillus licheniformisUV-9 for detergent formulations. Songklanakarin J. Sci. Technol. 2013;35(2):187-195.

- Rahayu S., Syah D., Suwanto A.,Suhartono M. T. Preliminary studi on keratinase from two Indonesian isolates. Anim. Prod. 2010;12(1):60-68.

- Rahayu S., Syah D., Suhartono M. T. Degradation of Keratin by Keratinase and Disulfide Reductase from Bacillus MTS of Indonesian Origin. J of Biocat. and Agric. Biotechnol. 2012;1(1):152-158. Doi: 10.1016/j.bcab.2012.02.001.

CrossRef - Macedo A. J., Beys-da-silva W.,Gava R., Termignoni C. Novel keratinase from Bacillus subtilis S14 exhibiting remarkable dehairing capabilities. Environ. Microbiol. 2005;71(1):594-596.

CrossRef - Lin X., Lee S. W., Bae H. D., Shelford J. A., Cheng K. J. Comparison of two feather-degrading Bacillus licheniformis Asian-Aust. J. Anim. Sci. 2001;14(12):1769-1674.

- Waterborg J. H. The Bradford Method for Protein Quantitation. In Walker J. M., ed. The Protein Protocols Handbook. 2nd Totowa-NewJersey Humana Press Inc. 2001;15-22.

- Walter H. E. Proteinases (protein as substrates) Method with haemoglobin casein and azocoll as substrate. In :Methods of Enzymatic Analysis. Bergmeyer J. and Grassl M., ed. 3th Weinheim: Verlag Chemie. 1984;270-278.

- Serrano A.,Rivas J.,Losada M. Purification and properties of glutathione reductase from Cyanobacterium Anabaena Strain 7119. J. Bacteriology. 1984;158(1):317-324.

- B.,Tanksale A. M., Ghatge M. S.,Deshpande V. V. Molecular and biotechnological aspects of microbial proteases. Microbiol. Mol. Biol. Rev. 1998;62(2):597–635.

- Gupta R and Ramnani P. Microbial keratinases and their prospective applications: an overview. Microbiol. Biotechnol. 2006;70:21–33.

CrossRef - Skrzydlewska E. R., Moniuszko-Jakoniuk J. A comparison of methanol and ethanol effects on the activity and distribution of lysosomal proteases. Polish J. of Environ. Studies. 1999;8(4):251-257

- Meng F. G.,Hong Y. K., He H. W., Lyubarev A. E., Kurganov B. I., Yan Y. B., Zhou H. M. Osmophobic effect of glycerol on irreversible thermal denaturation of rabbit creatine kinase. Biophysical J. 2004;87(4):2247–2254.

CrossRef - Bernand S. A. Purification and characterization keratinase from Bacillus MTS. Thesis. Bogor Agriculture University-Indonesia. 2010.

- Erlendsson S., Moller M., Hederstedt L. Bacillus subtilis S to A is a thiol-disulfide oxido reductases important for spore cortex synthesis. J. Bacteriol. 2004;186(3):6230-6238.

CrossRef - Cornish-Bowden and Cardenas M. L. Chemistry of enzyme. In: Biotechnology Enzymes Technology (Kennedy J. F. ed). Weinheim-Germany V. C. H. Verlagsgesellschaft mb H. 1987;7:345-352.

- Wilson R. H and Lewis H. B. The cystine content of hair and epidermal tissues. 2006. Available at www.jbc.org/content/73/2/543.full.pdf (accessed February 12, 2008).

This work is licensed under a Creative Commons Attribution 4.0 International License.