How to Cite | Publication History | PlumX Article Matrix

Cost Analysis of Solar Cabinet Dryer for Drying Dates

N. Josephine Selvi1, G. Baskar2 and Aruna Singh3

1Department of Chemical Engineering, Sathyabama University, Chennai.

2Department of Biotechnology St. Joseph’s College of Engineering, Chennai.

3Department of Chemical Engineering Vellore Institute of Technology, Vellore.

Corresponding Author E-mail: njoe14@gmail.com

DOI : http://dx.doi.org/10.13005/bbra/2541

ABSTRACT: Solar cabinet dryer for drying of dates is one of the promising technology for obtaining good quality dried dates which is again energy and cost effective technology. From the cost analysis of the solar cabinet dryer installed at CCE, Oman there is a clear indication that the energy per unit cost was comparable to any other modern drying technology like freeze drying, where energy consumption is more. As per the annual life cycle costing (ALCC) carried out for solar cabinet dryer the cost per unit energy obtained was Rs.63.36/kWh, when 5 hours of potential sunshine hour was taken into account. Under the test condition, the specific moisture extraction rate was found to be 0.84 kg/kWh and it took only 24 hours to dry dates from moisture content of 49.01% to 35.21% in cabinet dryer compared to sun drying which took 48 hours which is double. In the presence of heat storage unit, the thermal efficiency of solar dryer for forced convection drying obtained for the period of study was 26%. Due to the presence of heat storage unit five plus two hours extended drying time was available. In that case the cost per unit energy was Rs. 45.28/kWh. If this solar dryer unit is produced in bulk surely the production cost or the capital cost will come down drastically. This would in turn reduce the cost/unit of energy. However the cost of raw material and the selling price of dried dates were not taken into account. If they were taken into account surely more cost reduction could be expected.

KEYWORDS: Annual Life Cycle Costing;Cost Analysis;Capital Cost;Life Cycle Costing; Solar Cabinet Dryer; Sun Drying

Download this article as:| Copy the following to cite this article: Selvi N. J, Baskar G, Singh A. Cost Analysis of Solar Cabinet Dryer for Drying Dates. Biosci Biotech Res Asia 2017;14(3). |

| Copy the following to cite this URL: Selvi N. J, Baskar G, Singh A. Cost Analysis of Solar Cabinet Dryer for Drying Dates. Biosci Biotech Res Asia 2017;14(3). Available from: https://www.biotech-asia.org/?p=27350 |

Introduction

Open sun drying is conventionally used drying method by most of the farmers. But solar drying gives good quality nutritious end product without dust and insects, hence solar cabinet dryer could be the alternate for drying harvested products especially dates in country like Oman where solar energy is more abundant. In a study on performance of mixed mode solar dryer the drying rate and drying efficiency were reported as 113g/h and 10.24% respectively for solar drying only and 151g/h and 13.50% when the backup heater was used, both day and in the evening1.

In another review work it was mentioned that solar drying with desiccant bed is capable of drying products at late evening2. For solar drying, flat plate collectors with storage unit are more suitable and economical. In a solar cabinet dryer coupled with gravel bed for drying chilli, the heat stored in the storage unit could be used to dry the chilli during off sun shine hours. Extended drying time of 4h every day is reported in the work3. The evaluation of a solar thermal collector designed for drying grain was carried out for the geographical condition of Pakistan. The efficiency was higher in the month of November as compared to January4. It was concluded that thermal collector should be operated at high mass flow rates from 9.00 am to 4.00 pm to get maximum performance.

Selection of heater, blower and insulation thickness for optimum operation of the dryer for drying the grains were carried out in another work5. The new design eliminated the use of gas, drying time was reduced and the grains were moderately dried. Another work was based on the performance of a forced convection solar drier integrated with gravel. Average drier efficiency reported was 21% and specific moisture extraction rate was 0.87 kg/kWh6. The drying of cashew nuts using indirect solar dryer was carried out using active mode and passive mode of solar drying. In this study the thermal efficiency of the solar collector varied between 65-70% in active mode and 30-45% in passive mode7. Fuller et al. have carried out the technical and financial evaluation of solar dryer in Bhutan for drying of chilli and beef strips. They have reported that the total investment cost for the solar dryer solar dryer was Rs. 1,45,266 and the operating costs exceed the benefits. They suggest optimization of the dryer design to improve its financial benefit in addition to its favorable technical performance8. In another study in Malaysia for drying seaweeds, it is reported that using the double-pass solar collector is best suited as the payback period for the dryer is as low as 2.33 for the selected design parameters9. The aim of the current work is to carry out performance evaluation and cost analysis of solar cabinet dryer, especially to find the thermal efficiency of solar cabinet dryer and carry out annual life cycle costing.

Materials and Methods

The solar cabinet dryer, henceforth called as SCD designed and fabricated by the corresponding author, consist of the following 2 main units is used for the study as shown in Figure 1.

|

Figure 1: Solar Cabinet Dryer showing the drying cabinet and collector unit

|

Drying cabinet with insulation and

Flat plate collector integrated with heat storage unit covered with insulation.

Newly harvested rutab stage dates (soft light brown stage) were purchased from the local farms in Muscat and stored in the air conditioned room, temperature 20 oC for 3 days till it fully ripened to light brown color, Figure 2 and Figure 3

|

Figure 2: Rutab stage Date from farm (day 1)

|

|

Figure 3: Date used for drying (day 3)

|

Open sun drying

Dates are spread under open sun in an area of 76 x 80 cm, shown in Figure 4. The initial weight of the dates was recorded. The experiment started at 7.00 am. Every half an hour the change in the weight was recorded. Also the value of the ambient temperature and humidity of the air measured and recorded.

Solar cabinet drying

Dates were spread on 4 trays as shown in Figure 4. Initial weight noted. Random samples were taken from the trays and oven dried at 105oC to find the dry weight of the sample. After loading the trays the door of the dryer was closed tightly. Blower was started and waited till the system reached steady state. Temperature of the drying cabinet was measured in 3 places, inlet, middle and the exit using thermocouples. Similarly temperature of the heat storage box was recorded in 3 different places top, middle and the bottom. Ambient temperature and the temperature at the inlet and exit of the solar collector were also recorded. This experiment was conducted in the month of August. All the temperature measurements were recorded every 30 minutes. Solar intensity on the day of drying was also recorded every 30 minutes. Change in the weight of the dates placed in cabinet dryer was recorded every 1 hr to minimize the heat losses.

|

Figure 4: Cabinet drying and sun drying

|

For the determination of moisture content randomly selected dates samples were kept in the hot air oven at 105+1 oC. The dates were dried till they reached constant weight. Moisture content on wet basis is recorded for both sun dried dates and solar cabinet dried dates for every 1hr. Moisture content was calculated as per the following equation

Mwb= {(Mw-Md)/Mw}× 100 (1)

Where Mw is the initial mass in kg before drying and Md is the mass of dry dates in kg after drying. Specific moisture extraction rate is the energy required to remove one kg of water. It was calculated using the following relation8

SMER = Md / Pd (2)

Where Pd is the blower power. The instantaneous thermal efficiency of the collector is determined as reported in the literature9,10&11.

ɳc= (ɸo / ɸA) × 100 (3)

Where ɳc is the thermal efficiency of the solar collector, ɸo is the heat output of the collector

Performance analysis of overall system

The overall system efficiency is found out by the following relations12 for forced convection solar drying and for natural convection solar drying respectively

ɳs= (mwhfg)/ (IAt +E) (4)

ɳs = (mw hfg )/ (IAt) (5)

where mw is the moisture evaporated at a time in kg, hfg is the latent heat of vaporization of water in KJ/Kg, A is the collector area in m2, t is time of drying in s, E is the energy consumption of blower in kWh

Cost Estimation

Life cycle costing or LCC refers to the accumulated worth of all the costs that are both recurring and non-recurring during the life period of system15. The different components taken into account for calculating LCC are capital cost, replacement cost, maintenance Cost and salvage value.

The Capital cost is the initial cost that is spent for purchase of Steel to fabricate the setup, blower, fan, 4mm thick glass used for glazing effect, black paint, Mechanical Structures to support the drying unit, flat plate collector, blower, insulation material, stones for heat storage material, thermocouple, anemometer, humidity meter, solar intensity meter, weighing balance, laboratory analysis and Installation Charges. Replacement cost is the cost incurred for replacing blowers, fans, and puff beadings at the end of its life time. Blowers and fans should be replaced every 3 years. Maintenance cost is the cost incurred every year as annual maintenance cost. Salvage value is the money that is obtained while disposing the cabinet dryer and flat plate collector at the end of life cycle period.

For calculating LCC, each of the costs is converted to its present worth15. Even the salvage amount is converted to its present worth for calculating LCC. Following are the actual costs of various components that are considered for LCC calculations shown in Table 1. The currency used here is Indian Rupees. The first 10 items adds up to the capital cost. This is equal to Rs. 3,84,000. Assuming the maximum life of solar cabinet dryer and the flat plate collector is 20 years, it means the replacement of the setup should be done after 20 years, further calculations are carried out. Since the experiment was carried out under the metrological condition of Oman, the prevailing interest rate and inflation rate in Oman was taken into consideration

Table 1: Cost incurred in manufacture of the solar Dryer

| 1. | Cost of Cabinet dryer and flat plate collector | 1,52,000 |

| 2. | Fabrication charges | 80,000 |

| 3. | Weighing Balance | 12,800 |

| 4. | Humidity meter | 11,200 |

| 5. | Solar intensity meter | 14,400 |

| 6. | Dates | 12,800 |

| 7. | Stones | 9,600 |

| 8. | Insulation material | 43,200 |

| 9. | Cost of installation and Commissioning | 40,000 |

| 10. | Anemometer | 8000 |

| 11. | Annual maintenance charges | 8000 |

| Total | 3,92,000 |

Interest rate in Oman, i = 7%

Inflation rate in Oman, f = 4%

Peak Sun Hours for Oman is taken as 5 hours and 2 hours of extended drying time was considered due to the presence of heat storage unit in the experimental setup. For this 7 hours, total energy generated/day,

E = power x drying time (6)

E = 390 W x 7 h

To calculate the present worth of each expenditure (cost at year 0), the present worth of capital cost is directly taken from the capital cost (PW1). Let the replacement cost of the unit is U, then the present worth of replacement cost is calculated using the following equation

PW2 = U((1+f)/(1+i))^20 (7)

The present worth of the annual maintenance cost considered over the period of 20 years is

PW3 = AMC ((1+f)/(1+i))x[1-((1+f)/(1+i))^20] (8)

Since there is no moving parts, Assume the dryer should be replaced after 20 years, then the present worth of the salvage value obtained by disposing the unit and mechanical frames at the end of 20 years is

PW4 = Sal ((1+f)/(1+i))^20 (9)

Therefore the Life Cycle Cost, LCC and the annual life cycle costing is calculated from the following expression as

LCC = PW1 + PW2 + PW3 – PW4 (10)

ALCC = LCC/ {((1+f)/(1+i))x[1-((1+f)/(1+i))^20]} (11)

The cost per unit of energy is calculated by using the expression

Cost per unit energy = Total cost / (365 days x power) (12)

Results and Discussion

In the drying test carried out in solar cabinet dryer, the initial weight of the date recorded was 42.23 kg and every 1 hour the change in weight was recorded. The bone dry weight recorded by oven drying method was 21.53 kg. In the Cabinet dryer the initial moisture content of the date was 49.02% and final moisture content was 35.21%. Within 24 hours time (2 days) the moisture content was reduced to 35.21%. Whereas open sun drying took 48 hours (4 days) to reduce to the same level of moisture content.

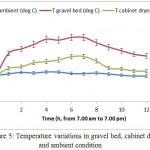

In addition to that in cabinet drying, the soft texture of the date was preserved. Browning was less compared to the open sun dried date. The final product was clean, free of dust and termites. The change in temperature of gravel bed, change in temperature of cabinet dryer and change in ambient temperature with respect to time is shown in Figure 5.

|

Figure 5: Temperature variations in gravel bed, cabinet dryer and ambient condition

|

The solar insolation data on the day of the experiment shows it is a sunny day. The temperature in the gravel bed is under increasing trend during the afternoon hour up to 17.00 hours. This may be due to the absorption and accumulation of solar energy in the gravel bed. At 19.00 hours the temperature of the gravel bed is 52 oC which is still higher than ambient temperature by 29.3 oC. Hence there is some unused heat present in the gravel bed unit which could be used effectively. Similarly at 17.00 hours the cabinet dryer temperature is close to ambient temperature but not equal to it. This is an indication that drying time could be further extended.

The average atmospheric temperature, gravel bed temperature and cabinet temperature was found to be in the range of 29.3oC to 33.8oC, 30oC to 73oC and 30.2oC to 51.5oC, Figure 5. In spite of maximum ambient temperature 33.8oC, the drying cabinet could attain a temperature of 51.5oC, a difference of 17.7oC is attained, and this may be due to the presence of insulation, which is close to the temperature reported by Kamble et al (2013)3.

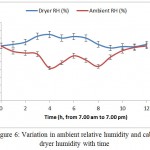

The maximum temperature attained in the gravel bed is 73 oC, this is attributed to good insulation of the heat storage unit, and heat holding capacity of the chosen heat storage material. The average solar insolation ranges from 928.9 w/m2 to 128.2 w/m2. The relative humidity of the atmosphere varies from 41.8% to 70%, Figure 6. The thermal efficiency of solar dryer for forced convection drying obtained for the month of August is 26%. The specific moisture extraction rate was found to be 0.84 kg/kWh. The humidity in the dryer increases in the beginning reaches a maximum of 84.6 % and then reduces as the drying advances, Figure 6.

|

Figure 6: Variation in ambient relative humidity and cabinet dryer humidity with time

|

Life cycle costing (LCC) and the Annual life cycle costing (ALCC) for the solar cabinet dryer were calculated. The results were more promising. For 5 hours of potential sunshine in Oman the cost per unit quantity of energy was calculated as Rs. 63.36/kWh. Whereas the cost for 5 hours plus 2 hours, this extended drying time obtained by heat storage unit, the cost of the energy was Rs. 45.28. There was a saving of Rs. 18.08, for every unit of energy produced when heat storage unit was used. This was slightly greater than one third of the original cost. However the cost of raw material and selling price of the finished product are not considered.

Conclusion

The drier with heat storage material helps to avoid fluctuations in drier air temperature. It took only 24 hours to dry dates from moisture content of 49.01% to 35.21% in cabinet dryer compared to sun drying which took 48 hours which is double, hence solar cabinet dryer is more effective than sun drying. Moreover the dates dried using cabinet drier retained its soft texture and are clean and dust/insects free. Browning of the skin and skin separation is also less. Even though the thermal efficiency is low in the order of 26%, solar cabinet dryer uses renewable energy source, which is available free of cost and drying time is less compared to open sun drying and final product quality is good. Also the cost per unit of energy is comparable, Rs 45.28/kWh to any other drying technology, hence suitable for villages where power is a major issue, hence it is recommended to farmers for drying freshly harvested agricultural products like dates and it could be extended to other agricultural products as well.

Acknowledgement and Funding source

The research leading to these results has received Project Funding from The Research Council of the Sultanate of Oman under Research Agreement No. ORG/CCE/EI/13/009. Authors would acknowledge the support and encouragement received from The Research Council as well as Caledonian College of Engineering, Muscat Sultanate of Oman.

References

- Donkor B. Thesis: performance evaluation of a mixed mode solar dryer incoporating a backup heater for drying cocoyam slices. Kwame Nkrumah University Of Science And Technology, Kumasi. May 2017.

- Sundari A. R. U., Veeramanipriya, E. A review of solar dryers for drying agricultural products. Indian Journal of Scientific Research. 2017;14(1):311-317.

- Kamble A. K., Pardeshi I. L., Singh P. L and Ade, G. S. Drying of chilli using solar cabinet dryer coupled with gravel bed heat storage system. Journal of Food Research. 2013;1(2):87-94.

- Khalil M. H. et al. Development and evaluation of a solar thermal collector designed for drying grain. Iranica Journal of Energy & Environment. 2012;3(4):381-385.

- Stephen K. A and Emmanuel S. Improvement on the design of a cabinet grain dryer. American Journal of Engineering and Applied Sciences. 2009;2(1):217-228.

CrossRef - Mohanraj P and Chandrasekar. Performance of a forced convection solar drier integrated with gravel as heat storage material for chili drying. Journal of Engineering Science and Technology. 2009;4(3).

- Dhanushkodi S., Wilson V. H and Sudhakar K . Thermal Performance Evaluation of Indirect Forced Cabinet Solar Dryer for Cashew Drying. American-Eurasian Journal of Agriculture & Environmental Science. 2014;14(11):1248-1254.

- Shanmugam and Natarajan E. Experimental investigation of forced convection and desiccant integrated solar dryer. Renewable Energy. 2006;31:1239-1251.

- Ahmed G. Performance evaluation of a mixedmode solar dryer for evaporating moisture in beans. Journal of Agricultural Biotechnology and Sustainable Development. 2011;3(4):65-71.

- Behessiotis V and Delyannis E. Solar drying. Laboratory of solar and other energy systems, NSRC “DEMOKRITOS”, P.O. Box: 60228, Aghia- Paraskevi, Greece. 2010;153-10.

- Sharma A., Chen C. R and Lan N. Y. V. Solar energy drying systems. Department of Mechanical Engineering, Kun Shan University,. 949, Da-Wan Road, Yung-Kang city, Tainan Hsien 71003, Taiwan. 2008.

- Koyuncu. Performance of various designs of solar air heaters for drying applications. Renewable Energy. 2006;31:1073–1088.

CrossRef - Garmo P. E., William G. S., James A. B., Elin M W. Engineering Economy’, 10th Edition, Prentice Hall, New Jersey. 1997.

This work is licensed under a Creative Commons Attribution 4.0 International License.