How to Cite | Publication History | PlumX Article Matrix

Effects of Moringa Peregrina and Ferric Chloride (FeCl₃) on Water Treatment Sludge Dewatering

Ramtin Mazaheri1, Mostafa Tizghadam Ghazani2 and Abolghasem Alighardashi2

1Civil and Environmental Engineering, Faculty of Civil, Water and Environmental Engineering, Shahid Beheshti University, A.C., Tehran, Iran.

2Faculty member of Civil, Water and Environmental Engineering, Shahid Beheshti University, A.C., Tehran, Iran.

Corresponding Author E-mail: ramtinmazaheri1296@gmail.com

DOI : http://dx.doi.org/10.13005/bbra/2709

ABSTRACT: In the present study, an active component of Moringa peregrine (MP) was used in comparison with ferric chloride (FeCl₃) for the conditioning of water treatment sludge. The comparison was based on dewatering characteristics of the conditioned sludge determined by capillary suction time (CST), specific resistance to filtration (SRF), tests of time of filtration (TTF) and sludge cake moisture content. The results indicated that MP showed relatively comparable conditioning effect as ferric chloride. Sludge conditioned with ferric chloride, showed better results than MP. According to CST, SRF and tests of time of filtration (TTF) and sludge cake moisture content results, optimum dose for MP, and ferric chloride was 100 ml/l. From the results of the study it could be concluded that MP alone could be effectively used and replace ferric chloride for dewatering of water treatment sludge.

KEYWORDS: CST; Ferric Chloride; Moringa Peregrine; Sludge Cake Moisture; SRF; TTF

Download this article as:| Copy the following to cite this article: Mazaheri R, Ghazani M. T, Alighardashi A. Effects of Moringa Peregrina and Ferric Chloride (FeCl₃) on Water Treatment Sludge Dewatering. Biosci Biotech Res Asia 2018;15(4). |

| Copy the following to cite this URL: Mazaheri R, Ghazani M. T, Alighardashi A. Effects of Moringa Peregrina and Ferric Chloride (FeCl₃) on Water Treatment Sludge Dewatering. Biosci Biotech Res Asia 2018;15(4). Available from: https://www.biotech-asia.org/?p=32365 |

Introduction

There are several approaches for sludge management such as conditioning, dewatering, thickening and safe disposal to the environment. Since sludge contains water, any of the dewatering mechanisms with or without prior conditioning could be used to reduce water volume. According to Metcalf and Eddy (2003), the moisture content of sewage sludge is reduced from 90–99 to 65–85% using chemical conditioning. There are mechanical systems such as belt filter presses, centrifuges or gravity drainage and evaporation as in sand drying beds, for conducting dewatering process. In many areas, where the land is cheap and the climate condition is favorable, sand drying beds is a popular approach. In other respects, mechanical dewatering systems are good options. Procurement and running costs of mechanical systems are expensive in the developing world so sand drying beds can be a good option. The effective factors for gravity drainage depend on the nature of sludge, applied depth and extent of conditioning. In another study, in order to prepare the sewage sludge, a combination of polymers and substances such as sewage sludge ash, cement kiln dust, and bagasse were used. This was a successful combination for dewatering primary sludge from a wastewater treatment plant (Benítez, et al., 1994). Novak and Langford (1977) showed that air-drying is an effective procedure. Only the upper layer of unconditioned sludge would dry. In order to reduce the land requirement of sand beds, these important effects should be considered. There are various chemicals for sludge conditioning including ferric chloride, alum, lime and organic polymers.

The costs of chemical conditioning are more than half of the costs associated to sludge management and handling (Christensen and Stulc, 1979). Reducing such conditioning cost using available natural coagulants encourages water treatment plants in the developing countries to handle and dispose sludge properly.

Among the natural substances, the ability of Moringa Peregerina seeds powder for sewage treatment has been proven. Moringa, native to parts of Africa and Asia, is the sole genus in the flowering plant family Moringaceae (Mozaffarian, 2002).

Moringa as a tropical fast growing tree uses very low water. Seedpod is in the form of a drumstick. The tree measures about twelve meters in height and produces seed during the first year (Ndabigengesere et al., 2006). Folkard and Sutherland (1999) showed that the optimal concentration of Moringa to treat water is between 50 to 30mg per liter. In addition, this optimal concentration depends on the inlet water properties for treatment.

At a concentration of 20 to 60 mg / L and pH of 7 to 8.5, color reduction efficiency is 56 to 67%, while the color reduction efficiency of sodium chloride and potassium chloride is 53 and 64%, respectively (Krishna Prasad, 2008).

Ndabigengesere et al (2006) evaluated the performance of Alum and Moringa seeds for water treatment. They concluded that 80ml/L of Moringa can reduce the turbidity of water from 201 to 13.9 NTU and the efficiency is 93%.

Economically, in addition to the fact that the water turned into sewage is unusable, it also contaminates the surface water and groundwater source (Yazdani, 2009). Therefore, water as a limited critical source has been endangered in the world. Due to the health and economic considerations, attention to the production, collection and refurbishment of sewage is necessary and inevitable. In this research, water treatment was carried out using Moringa Peregrina seed powder and ferric chloride in such a way that it can be discharged into the environment.

Methodology

Sludge Sample

Sludge samples were obtained from the sedimentation tanks at Tehranpars water treatment plant. Ferric chloride is used as a precipitation agent for surface water treatment. The samples were stored at around 4 ◦C. Before each experiment, in order to bring the sludge to room temperature, the required volume of sludge was put outside the cooling room. Table 1 shows the characteristics of raw sludge sample.

Table 1: Characteristics of raw sludge from Tehranpars water treatment plant.

| Method of analysis | Mean value | Range | Parameter |

| Standard method (2540 B) | 4.24 | 4-4.49 | Total solids (TS, %) |

| Standard method (2540 E) | 80.18 | 75-90 | Volatile solids (g/kg TS) |

| JENWAY-3510 pH meter | 7.61 | 7.45-7.89 | pH |

| Buchner funnel | 1260 | 1080-1860 | TTF (s) |

| Buchner funnel | 1.61 | 2.373-1.374 | SRF (×1013 m/kg) |

| MRCST apparatus, reservoir with 18 mm in diameter | 44 | 36-52 | CST (s) |

Conditioning Chemicals

The materials used for conditioning were MP and ferric chloride. MP was obtained from the south of Iran. The seeds were stored at room temperature. The seed cover was removed just before the extraction and the kernel was powdered using a kitchen blender. 10 g powder was dissolved in 100 mL NaCl solution (1 M) to make a 10% solution and consequently the coagulant of MP seed was extracted. A magnetic stirrer was used to blend the solution for about 30 min. First, a 500 μm then a 100 μm pore size filters were used to filter the suspension. In some cases, to evaluate the effect of filtration, the MP solution was not filtered. The results showed that there was no difference between filtered and non-filtered solutions. Based on TS, VS analysis and MP organic nature, it was determined that the amount of effective material to prepare 10% MP solution (100000 mg/l) is 73400 mg/l at 105 and 550, respectively.

Laboratory analytical grade ferric chloride was prepared in 5% solution. Fresh MP and ferric chloride solution were prepared during each experiment.

Experimental Methods

A jar test apparatus was used to conduct sludge conditioning test. This apparatus has stirrer with speed control and three beakers (1 L size). Different amounts of conditioning chemicals were added to the beakers having sludge volumes of 250 mL. Conditioning process was done by using jar test apparatus, Rapid mixing was conducted at 100 rpm for 1 min and the intensity was reduced to 40 rpm and mixed further for about 15 min.

Dewatering

In order to conduct the dewatering experiments, a 9 cm standard Buchner funnel with a Whatman No. 1 filter paper, multi-radii CST (MRCST) unit (model TW 166 triton Electronics Ltd.), and sand columns were used.

Both Buchner funnel experiments and a MRCST unit were used to estimate SRF values. The suction pressure applied was determined 49 kPa during the Buchner funnel experiments. Filtrate volume, time and cake solids content were recorded. In order to estimate the SRF, slope of the curve of time/filtrate volume versus filtrate volume was used. In the MRCST unit, CST and SRF were measured using stainless steel tubes with an inner diameter of 10 and 18mm and a specific CST filter paper. It was also measured the time of filtrate wetting of the filter paper as the wet surface moves across several concentric circles of sensors. The manufacturer specifies that the second probe places at the same position as that of the standard CST apparatus. The reading at this probe was considered as the CST of the sludge. Manufacturer instructions were followed to estimate CST and SRF. The following formula was used to calculate SRF (Novak and Langford, 1977; O¨ zacar and Sengil, 2000).

![]()

where A, the area of the filter cake (m2);

P, the filtration pressure (N/m2);

μ, the viscosity of filtrate ((N s)/m2);

C, the sludge solids concentration (kg/m3);

b, the slope of the plot of time over filtrate volume against filtrate volume (s/m6).

From MRCST, P value was assumed 49 kPa for calculation of the SRF data. It is equal to the pressure normally set by the Buchner funnel apparatus. Average sludge solids concentration was about 0.03 g/mL.

There is a good correlation between the results of SRF obtained from the MRCST apparatus (18mm diameter reservoir) and those obtained from a Buchner funnel filtration (correlation coefficient of 0.82). Hence, MRCST unit experiments provide SRF data reported in this paper.

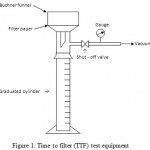

In this study, time to filtration (TTF) is determined using an apparatus. Figure 1 shows TTF test equipment.

|

Figure 1: Time to filter (TTF) test equipment.

|

Analyses

CST, and SRF, Time to filtration method (TTF) was used to measure the sludge dewaterability. According to the standard methods such as APHA, AWWA and WEF (1995), total solids concentration of sludge cake samples from the Buchner funnel filter and sand bed were measured.

Results and Discussion

The reduction of CST and SRF values showed that conditioning of the sludge with ferric chloride and MP improved the dewatering capacity. Accordingly, both ferric chloride and MP could be used to improve ferric chloride sludge filterability. Comparing both coagulants, ferric chloride had a slightly better performance. MP could be considered as the suitable coagulant, taking into account chemical cost, quality of sludge and sludge volume that should be handled.

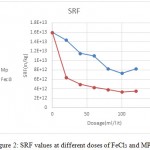

Specific resistance to filtration (SRF)

Figure 2 shows the results of SRF for ferric chloride-, MP- conditioned sludge. Both coagulants reduced the SRF of the raw sludge. The optimum dose for both MP and ferric chloride was around 100 mL/L. As the figure shows, doses beyond the optimum values did not reduce the SRF value further. Average SRF values of MP-, ferric chloride- conditioned sludge at the respective optimum doses were 1.21×1013 and 0.976 × 1013 m/kg, respectively.

|

Figure 2: SRF values at different doses of FeCl3 and MP

|

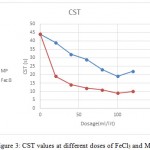

Capillary suction time (CST)

There was a similar trend in CST values for the conditioned sludge as in SRF. Figure 3 shows a typical result at different coagulant doses. Optimum dose for both MP and ferric chloride were 100 mL/L. The average CST value at optimum doses for MP-, ferric chloride- conditioned sludge were 19 and 9 s, respectively. The second probe of the MRCST apparatus was read to determine CST values as stated by the manufacturer.

|

Figure 3: CST values at different doses of FeCl3 and MP.

|

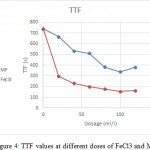

Time to filtration and solid cake moisture

CST, and SRF, Time to filtration method (TTF) only measure the sludge dewaterability and provide no information about the amount of moisture in dewatered sludge (some water in the sludge is in the form of bound water which is not easily removed by mechanical methods). In other words, the sludge may easily be filtered, but plenty of water will remain in the dewatered sludge (Chen et al., 2001). So, two methods of TTF and sludge cake moisture were used simultaneously to measure the sludge dewaterability of feCl3 and MP. According to figure 4, at the same dosages, ferric chloride provides the less time to filtration and more efficient dewaterability compared to MP. For example, at dosage of 100 mL/l in which the value of TTF is at the minimum level for both coagulants, the solid cake moisture of MP and ferric chloride is 91% and 76%, respectively. The minimum solid cake moisture of MP (82%) was observed at the dosage of 40 ml/l.

|

Figure 4: TTF values at different doses of FeCl3 and MP.

|

|

Figure 5: Solids concentration from sand column for varying doses of FeCl3 and MP.

|

Conclusions

In this study, the effectiveness of an extract from Moringa Peregrina (MP) and ferric chloride for conditioning sludge from Tehran water treatment plant was compared. CST, SRF, TTF and solid cake moisture were used to conduct the comparisons. The following conclusions were made.

Optimum dose of MP and ferric chloride for maximum CST and SRF reductions was 100 ml/l. The minimum solid cake moisture for MP and ferric chloride was observed at the dosages of 40 and 100 ml/l.

The results showed that MP and ferric chloride had relatively similar conditioning performance for water treatment sludge. Thus, MP alone could be a promising coagulant system for effective water treatment.

References

- APHA, AWWA and WEF: Standard Methods for the Examination of Water and Wastewater, 19th edn. 1995;2–54.

- Benitez J., Rodriguez A and Suarez A. Optimization Technique for Sewage Sludge Conditioning with Polymer and Skeleton Builders. Wat. Res. 1994;28:2067-2073.

- Chen Y., Yang H and Gu G. Effect of Acid and Surfactant Treatment on Activated Sludge Dewatering and Settling. Wat. Re. 2001;35:2615-2620.

- Christensen G. L and Stulc D. A.: ‘Chemical reactions affecting filterability in iron-lime sludge conditioning’.J. Water Pollut. Control Fed. 1979;51:2499–2512.

- Folkard G. K., Sutherland J. P and Shaw R. “Water Clarification using Moringa oleifera seed Moringa oleifera.” Indian Council of Forestry Research and Education, Dehra Dun, India. 1999;10.

- Prasad R. K. Color removal from distillery spent wash through coagulation using Moringa oleifera seeds: Use of optimum response surface methodology.of Hazardous Materials. 2008;165(1-3):1-8.

- Metcalf and Eddy Inc. (Revised by Tchobanoglous G., Burton F. L and Stensel H. D.) Wastewater Engineering: Treatment and Reuse, 4th edn., McGraw-Hill, New York. 2003;850.

- Mozaffarian V. Culture of plants in Iran, Farhange Moaser Pub., Tehran. (In Persian). 2002.

- Ndabigengesere S. C., Katayon S., Noor M.J. M. M and Abdullah A. G. L. The effectiveness of moringa oleifera as primary coagulant in high-rate settling pilot scale water treatment plant. International J. of Engineering and Technology. 2006;3(2):191-200.

- Novak J. T and Langford M.: The use of polymers for improving chemical sludge dewatering on sand beds’.AWWA 1977;69(2):106–110.

- O¨zacar M and Sengil I. A. Effectiveness of tannins obtained from valonia as a coagulant aid for dewatering of sludge. Wat. Res. 2000;34(4):1407–1412.

- Yazdani V. Evaluting of performance of powdered seeds of some species of Moringa tree (family Moringaceae) in comparison with alum and poly aluminium chloride (PAC) in urban wastewater treatment. M.Sc. Thesis of Irrigation and Drainage, Bu-Ali Sina University, Hamedan. (In Persian). 2009.

This work is licensed under a Creative Commons Attribution 4.0 International License.