How to Cite | Publication History | PlumX Article Matrix

Kinetics of saponification of Treculia africana oil using a locally sourced alkaline

A. K. Asiagwu, P. E. Omuku, A. C. Ilabor and C. A. Omeoga

Department of Pure and Industrial Chemistry Nnamdi Azikiwe University, Awka Nigeria.

Corresponding Author E-mail: drasiagwu@yahoo.com

ABSTRACT: The investigation on the saponification of treculia africana (breadfruit) oil via a locally obtained alkaline (Ngu) an extract of the burnt females inflorescence of oil palm bunch using kinetic approach proved successful and showed a high degree in the possibility of producing good quality toilet soap. The result obtained revealed that the reaction is essentially first order with respect to the caustic alkaline (KOH) derived from Ngu. The reaction constant averaged to 0.0695 minutes-1 and reaction tended to completion on the average of 30 minutes with a half life of 9.96 minutes. The reaction rate was substantially influenced by the various concentrations of the Ngu as the saponification time-rate approached maximum with the highest concentration of Ngu. The soap produced from the sample was milky and soft and lathered well. The texture can be improved or hardened if necessary.

KEYWORDS: Reaction rates; reaction constant half life in saponification process

Download this article as:| Copy the following to cite this article: Asiagwu A. K, Omuku P. E, Ilabor A. C, Omeoga C. A. Kinetics of saponification of Treculia africana oil using a locally sourced alkaline. Biosci Biotechnol Res Asia 2008;5(1) |

| Copy the following to cite this URL: Asiagwu A. K, Omuku P. E, Ilabor A. C, Omeoga C. A. Kinetics of saponification of Treculia africana oil using a locally sourced alkaline. Biosci Biotechnol Res Asia 2008;5(1). Available from: https://www.biotech-asia.org/?p=6565 |

Introduction

Soap is an important surface- active agent and it is chemically the alkali metal salts of long-chain fatty acid. The most commonly used fat and oils for production of soap through saponification reactions are animal fallow, coconut oil, and palm oil, palm kernel oil and linoseed oil. Similarly, potassium and sodium hydroxide are widely used as caustic alkalis for the purpose [1]. The demand for these materials for various other domestic and industrial application are high resulting in their high costs. Consequently, there is a need to explore unconventional sources of oils and caustic alkalis for the production of soap and to determine by means of kinetic approach, the optimum reacting conditions for efficiency and utilization of the process. Several workers reported the use of caustic alkalis from ash for soap production and the effects of a number of factors, notably temperature, ash particle size, etc on the yield of caustic alkali [2,3].

The physico-chemical characteristics of seed oils from plant in the world have been reported [4-6]. One of such oil is obtained from a Treculia africana and has saponification value of 1960 5-210. It is found mainly in the south east and south-south zone in the country. The percentage of seed oil is significant. The seed is a rich source of protein, carbohydrate, vitamins and also a possible source of raw materials for the production of vegetable oils, soaps etc [7].

This present study is aimed at determining the appropriate reacting conditions that will improve the viability of the saponfication process of locally sourced alkali with an unconventional source of oil via kinetic studies. It will also establish a suitable alternative to the usual palm kernel oil or in special case, coconut oil for use for quality toilet soap production, using raw materials t which are locally obtained in Nigeria.

Materials and Methods

The breadfruit seed used was obtained from a local market in Onitsha, pulverized with a grinding machine. A measured amount of the pulverized cake was introduced into a thimble and the solvent (n-hexane) 100m/s was poured into the extractor flash and heat was applied. It was allowed for over 20-25 minutes for complete extraction of the oil. The procedure was repeated severally to obtain much quantity of the oil. The miscella was then distilled in an oven at 1050c for 2 hours to recover the solvent and to concentrate the oil via distillation process [7].

The alkali use in this study was obtained by dissolving 120g of sieved ash of burnt female palm bunch in a distilled water agitated for 5minutes and allowed to stand for 12 hours. The material was decanted and the brownish filtrate was heated. The temperature was maintained at 400c for 10 minutes. The bleached alkali was separated from the spent earth by filteration using whatman A1 (24cm) filter paper on conical flask to recover the alkali (KoH) which was then water-clear. The concentration of the solution of local alkali (ngu) produced was determined after bleaching the ngu extract with active earth to water-clear. It was further concentrated by boiling and evaporation for some hours. 5mls of the solution of Ngu extract was titrated against freshly made 0.5m HCL for the kinetic study, three different concentrations of the alkali extract was used (1.59mol/L, 2.58Mol/L and 5.08 mol/L).

The fully boiled process of soap production was used in the saponification of traculie African oil using local alkaline extract. 50ml of the oil was measured into a beaker and a steam generator was introduced to raise the temperature to about 7100C (This exposes the free fatty acids present in the oil). After 2 minutes of heating, the oil was left to cool at 400C.

5g of the oil dissolved in 20ml of the fat solvent (ethanol) was introduced into a beaker containing 20ml of 5.08mol/L of the KOH (Ngu) and the mixture was constantly stirred. An aliquot, 5ml of the broth was taken every 3 minutes into a conical flask that contain 20ml of 100C old distilled water and shaken. The content was then titrated against 0.5MHCL to a phenolphthalein end paint and the litre values recorded. The experiment was repeated for different concentration of the KOH (Ngu); 2.58mol/L and 1.59/Mol/L respectively.

5ml of the saponifying mixture was withdrawn at interval of 3 minutes and titrated against 0.5MHCL as above to determine the residual concentration of the KOH in Ngu, until the concentration reduced to a constant value when the saponification was complete [5-8]

With the values appropriate plots were produced (KOH/(KOH) against time) to obtain both the order of reaction, reaction constant Ko to confirm the result, the half life plot was also produced.

Results and Discussion

In the reaction between the treculia Africana (Bread fruit) oil and Ngu (KOH) a local alkali extract, the dominant fatty acid contained in the oil are linoleic and oleic acids. These fatty acids were hydrolysed according to the following steps.

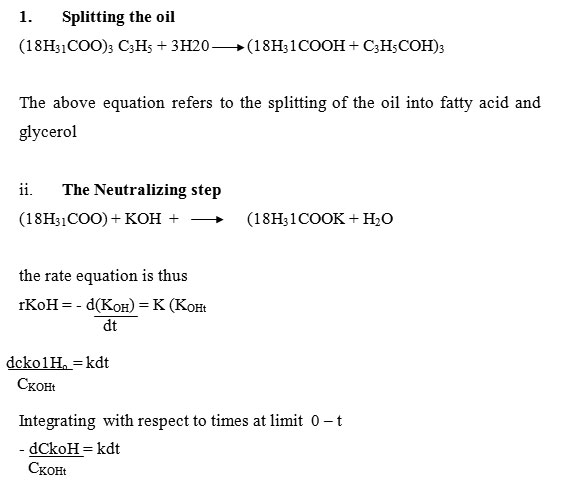

Splitting the oil

(18H31COO)3 C3H5 + 3H20 (18H31COOH + C3H5COH)3

The above equation refers to the splitting of the oil into fatty acid and glycerol

CkoH0/CkoHt) versus time (t), produced straight line (fig 1-iv). This shows that the reaction between the breadfruit oil are Ngu (KOH) was essentially first order and the rate constant (kc) averaged to 0.0696min-1. calculating the half life based on the concentration (KOH0=2.58mol/L) as in figure II, the result obtained confirmed a typical first order reaction with t½ = 9.96 minutes [8].

The reaction (saponification process) was observed to increase with initial concentration of the Ngu. This was why the saponification of breadfruit oil with Ngu took shorter time to go to completion. This is thus an evidence to prove that saponification of breadfruit oil and Ngu (KOH) was concentration and time dependent. Nevertheless, a high quality soap was produced in the process [7,9]

Figure iv show, the effect of changes in concentration of KOH with time at various initial concentration of KOH. When CkoH0 = 5.08ml/l, the saponification reaction between breadfruit and KOH (Ngu), came to completion at a faster rate and it took the total alkali 23 minutes to be consumed in the reaction [10]. On the other hand, as the relative initial concentrations were reduced by serially diluting the KOH, with distilled water, to obtain lesser concentration of KoH0 = 2.58ml/L and CkoH0 = r.59mol/L respectively. The duration of the reaction was progressively becoming slower with time limit extending to 33 and 39 minutes respectively. This phenomenon indicates that the reaction is evidently concentration dependent[8].

When a graph of InCKoH0/CKoHt was plotted against time for each of the concentrations, the curves obtained (figure I-III) were straight lines with postive magnitude. The calculated concentrations at instant for the reactions ln(CKOH/CKOHt), while the curves for the order of reaction and reaction constant are shown in figure I-II, the half life curve was produced in figure IV. [10].

Conclusion

A first order reaction was obtained in the saponfication of breadfruit oil with Ngu. The average rate constant was 0.069 min-1. and the half life value of 9.96 minutes, the reaction rate was a function of the initial concentration of local alkali. The soft soap produced could be modified into a hard soap. Notwithstanding the overall cost of production of a high quality, long lasting and wonderful lather soap using these raw materials makes it economically attractive. The results of this work is reliable for use in the design of a hydrolyser for commercial processing.

References

- J.C. Eremosale (1997); Biochemical and natural characteristics of the seed and oil from wild plants. Proceedings, 2nd International workshop on African New sources of vegetable oils Cameroon pp. 203-2008.

- J.C. Eremosale and C. O. Eremosale (1993), studies on the chemical composition and physico-chemical properties of seeds and some wild plant. Plant food. Human Nutrition 43. 251-258.

- J. C. Eremosale C. O. Eremosele A. O. Akinonye and T. O. Koralafa (1994); Characterisation of oils and chemical analysis of the seeds of wild plant. Plant foods. Human Nut. 461 361-365.

- A. O. Kuye and C. Okarie (1990), Factors affecting the use of palm bunch, such as ash-a source of alkali for soap production, Ife Technology 2:33.

- Longman G. F. (1976). The analysis of detergent and detergent product, John Willey 545-577.

- Nigeria Industrial Standard (1973), Specification for toilet soap. Nigerian Standard Organization UDC 99.

- V.I.E Ajiwe C. A. Okeke and H. U. Agbo (1995) Bioresources Technology Volume 33 No. 2: 183-184.

- J. A. Okeke O. Okon, A. K. Awa (1999), Production of soap from …butter with Ngu as source of caustic alkalis Nig. Soc. Chem.. Enugu 37.

- Shrieve R. M. (1977), Chemical Process Industries McGraw-Hill New York.

- A. O. Ogbunbayo and R. A. Bello (1995). The Effective of the substitution of the oil extracted from varieties of mango seeds for Tallow in soap making National Society of chemical Engineering 14 vol 1& 2 63-66.

This work is licensed under a Creative Commons Attribution 4.0 International License.