How to Cite | Publication History | PlumX Article Matrix

Arun Kumar1*, Pankaj Kumar Sharma2 and Pradeep kumar3

1NKBR Colege of Pharmacy and Research Center, Meerut India.

2Raj Kumar Goel Institute of Technology, Ghaziabad India.

3pes College of Pharmacy, Bangalore India.

ABSTRACT: Mouth dissolving tablet of glipizide was prepared by using the micro encapsules of Ethylcellulose. The micro encapsules was prepared by Coacervation-phase separation method by using different polymers like Xanthan gum, HPMC and Ethylcellulose. The best result was fond of Ethylcellulose. Mouths feel taste was excellent after studied on 10 volunteers and no bitter taste or grittiness claimed by volunteers. The % drug release was 95.95% in 24 hrs which is much better then other formulations. The study was of Fast release component for quick onset of action by absorption through oral mucosa. Controlled release component, which will form a suspension in the oral cavity and after swallowing of the suspension, will provide sustained action of the drug. Purpose to included controlled component in mouth dissolving tablet is that to reduce dosing frequency, Increase t½ and controlled blood glucose level for prolonged period of time. This has been achieved after disintegration and dissolution studied the mouth dissolving tablets of glipizide by using the micro encapsulation technique. Problems of swallowing encountered by pediatric and geriatric patients can be overcome by formulating mouth-dissolving tablets.

KEYWORDS: Glipizide; fast release; mouth dissolving tablets; micro encapsulation; xanthan gum

Download this article as:| Copy the following to cite this article: Kumar A, Sharma P. K, kumar P. Formulation of Mouth Dissolving Tablets of Glipizide by Microencapsulation Technique Using Various Polymers. Biosci Biotechnol Res Asia 2009;6(1) |

| Copy the following to cite this URL: Kumar A, Sharma P. K, kumar P. Formulation of Mouth Dissolving Tablets of Glipizide by Microencapsulation Technique Using Various Polymers. Biosci Biotechnol Res Asia 2009;6(1) . Available from: https://www.biotech-asia.org/?p=8174 |

Introduction

Recent developments in technology have presented viable dosage alternatives for patients who may have difficulty swallowing tablets or liquids. Traditional tablets and capsules administered with an 8-oz. glass of water may be inconvenient or impractical for some patients. For example, a very elderly patient may not be able to swallow a daily dose of antidepressant. An eight-year-old with allergies could use a more convenient dosage form than antihistamine syrup. A schizophrenic patient in the institutional setting can hide a conventional tablet under his or her tongue to avoid their daily dose of an atypical antipsychotic. A middle-aged woman undergoing radiation therapy for breast cancer may be too nauseous to swallow her H2-blocker. Fast-dissolving/disintegrating tablets (FDDTs) are a perfect fit for all of these patients. [1]

FDDTs disintegrate and/or dissolve rapidly in the saliva without the need for water. Some tablets are designed to dissolve in saliva remarkably fast, within a few seconds, and are true fast-dissolving tablets. Others contain agents to enhance the rate of tablet disintegration in the oral cavity, and are more appropriately termed fast-disintegrating tablets, as they may take up to a minute to completely disintegrate. [1]

The target populations for these new fast-dissolving/disintegrating dosage forms have generally been pediatric, geriatric, and bedridden or developmentally disabled patients. Patients with persistent nausea, who are traveling, or who have little or no access to water are also good candidates for FDDTs.1 In the near future, other patient populations will also be targeted. A novel application for FDDTs is in veterinary medicine, for example, to avoid pilling a cat. With fast-dissolving/disintegrating dosage forms increasingly available, it will be likely that prescribes will recommend such products for their noncompliant patients. The ease of administration of a fast-dissolving/disintegrating tablet, along with its pleasant taste, may encourage a patient to adhere to a daily medication regimen. Although a FDDT may not solve all compliance issues, it may be enough of an advance to be of therapeutic significance.

The major advantage of the FDDT formulation is that it combines the advantages of both liquid and conventional tablet formulations, while also offering advantages over both traditional dosage forms.2 it provides the convenience of a tablet formulation, while also allowing the ease of swallowing provided by a liquid formulation. FDDTs allow the luxury of much more accurate dosing than the primary alternative, oral liquids.

A major claim of the some FDDTs is increased bioavailability compared to traditional tablets.1 Because of dispersion in saliva while still in the oral cavity; there can be pre-gastric absorption from some formulations in those cases where the drug dissolves quickly. Buccal, pharyngeal and gastric regions are all areas of absorption of the many formulations.3 However, other formulations show nearly identical plasma-concentration profiles.2 Any pre-gastric absorption avoids first pass metabolism and can be a great advantage in drugs that undergo a great deal of hepatic metabolism. However, if the amount of swallowed drug varies, there is the potential for inconsistent bioavailability. While the claimed increase in bioavailability is disputable, it is clear that the major advantage of these formulations is convenience

Pharmaceutical marketing is another reason for the increase in available fast-dissolving/disintegrating products. As a drug entity nears the end of its patent life, it is common for pharmaceutical manufacturers to develop a given drug entity in a new and improved dosage form. A new dosage form allows a manufacturer to extend market exclusivity, while offering its patient population a more convenient dosage form or dosing regimen. In this regard, fast-dissolving/disintegrating tablet formulations are similar to many sustained release formulations that are now commonly available. An extension of market exclusivity, which can be provided by a fast-dissolving/disintegrating dosage form, leads to increased revenue, while also targeting underserved and undertreated patient populations. Although the cost to manufacture these specialized dosage forms exceeds that of traditional tablets, this additional cost is not being passed on to the consumer. Therefore, cost is generally not an issue when recommending these new dosage forms.

Pharmacists can expect to see an increase in the number of drug products available in FDDT formulations.

Procedure

Microcapsules were prepared by the coacervation-phase separation technique using ethyl cellulose (CDH, BATCH NO.02129), Weight accurately according to excipients-drug ratio 4:1; Initially cyclohaxane (Merck) placed over hot plate & magnetic stirrer, temperature maintained at 80oc, Added ethylcellulose and stirrered vigorously until dissolved or make viscous mass that is called preparation of coating material, Drug dispersed into coating material slowly and maintained temperature at 60oc for 5minutes, than only magnetic stirrer speed at their high level & temperature mode is off, After sometimes sample was taken and detected on photomicroscope for preliminary study, if microencapsulation coating over core material is started or not, if started then stirrer vigorously for 30minutes, After that cool at room temperature for15minutes, than placed over ice tray for proper solidification, Finally washed with cyclohaxane & filtered through wattman filter paper and dry it.

HPMC and xanthan gum microincapsules was prepared by aqueous coacervation-phase separation method, in aqueous phase coacervation separation process, a polymeric macromolecular wall material is dissolved or dispersed as a solution in water. The hydrophobic core material to be encapsulated is dispersed in the aqueous phase. Encapsulation occurs when the core material is salted out and encases the core substances after addition of 20% solution of sodium sulfate.

Characterization Of The Drug By

Thin Layer Chromatography

The TLC plates showed a single compact spot of glipizide with Rf value 0.833. No other spots due to degradation of drug could be located, indicating purity of drug used for the work.

Ultra Violet Spectroscopy

The UV Spectroscopy (UV 1700 Shimadzu) shows two absorption maxima at 226nm and 275nm. (Reported 226nm and 274nm).

Melting Point

Melting point of the glipizide sample was found to be 203 to 205oC

Solubility

The values of solubility in different solvent given below

1 part of glipizide dissolved in 44.643 *103 part of water.

1 part of glipizide dissolved in 109.34 part of chloroform.

1 part of glipizide dissolved in 35.273*103 part of diethyl ether.

1 part of glipizide dissolved in 30.147*103 part of glycerin.

1 part of glipizide dissolved in 732.7 part of alcohol.

1 part of glipizide dissolved in 321.34 part of polyethylene glycol

1 part of glipizide dissolved in 919.12 part of polypropylene glycol.

U.V Spectrophotometer

The standard curve of Glipizide is obtained by plotting the absorbance against the concentration of the drug is depicted in Fig-2.3 the r2 value was found to be 0.9995 and the value of the slope was found to be 0.02048.

H.P.L.C. Method

The standard curve of Glipizide as obtained by plotting the peak area vs concentration of drug is depicted. The value of the retention time was 3:32:5, the r2 value was found to be 0.9996 and the value of the slop was found to be 8.841 ± 0.360.

The angle of repose values varied from 36.24º to 36.69º. The bulk densities values varied from 0.25 to 0.27g/cc. The compressibility values are 5% no variations were observed. From these values, it was evident that these blends had excellent flow properties.

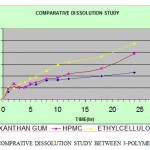

Comparative Dissolution Profile

TABLE: % DRUG RELEASE WITH TIME.

| S.NO. | TIME (hr) | XANTHAN GUM | HPMC

|

ETHYLCELLULOSE

|

| 1. | 1(pH-1.2) | 12.51 | 17.72 | 22.46

|

| 2. | 2(pH-1.2) | 21.39 | 26.31 | 20.59

|

| 3. | 3(pH-7.4) | 20.67 | 20.96 | 26.20

|

| 4. | 4(pH-7.4) | 21.02 | 20.08 | 29.59

|

| 5. | 5(pH-7.4) | 25.48 | 26.43 | 36.00

|

| 6. | 6(pH-7.4) | 25.61 | 29.07 | 38.86

|

| 7. | 8(pH-7.4) | 32.38 | 35.22 | 49.64

|

| 8. | 10(pH-7.4) | 33.44 | 36.66 | 58.85

|

| 9. | 12(pH-7.4) | 34.73 | 43.62 | 63.95

|

| 10. | 18(pH-7.4) | 39.66 | 52.34 | 73.55

|

| 11. | 24 (pH-7.4) | 45.61 | 77.82 | 95.65

|

|

Figure 1: Comprative Dissolution Study Between 3-Polymers.

|

Reason For Selection Of Ethylcellulose Over Hpmc, Xanthan Gum:

On the basis of drug release pattern from microencapsules on dissolution study.

Ethylcellulose is better floating properties than HPMC & Xanthan gum.

Ethyl cellulose coating is used to modify the release of a drug, to mask an unpleasant taste, or to improve the stability of a formulation; for example, where granules are coated with ethylcellulose to inhibit oxidation.

Conclusion

Problems of swallowing encountered by pediatric and geriatric patients can be overcome by formulating mouth-dissolving tablets. The Fast release component for quick onset of action by absorption through oral mucosa Controlled release component, which will form a suspension in the oral cavity and after swallowing of the suspension, will provide sustained action of the drug. Purpose to included controlled component in mouth dissolving tablet is that to reduce dosing frequency, Increase t½ and controlled blood glucose level for prolonged period of time. Ethylcellulose micro encapsulation shows the best result and F4 formulations having higher % drug release. After disintegration and dissolution studied this has been achieved.

Acknolegdement

The authors are grateful to Arbro Pharmaceuticals, Delhi (India) for providing the gift samples of Glipizide and Department of Pharmaceutical Sciences, Raj Kumar Goel Institute of Technology, Ghaziabad U.P (India) for providing the necessary research facilities.

Refrences

- Chang R K, Guo X, Burnside B, Couch R. 2000. Fast-Dissolving Tablets, Pharm Technol; 24(6): 52-58.

- Habib W, Khankari R, Hontz J. 2000. Fast-Dissolve Drug Delivery System. Crit Rev Ther Drug Carrier Syst; 17:61-72.

- Seager H. 1998. Drug-deliver Products and the Zydis Fast-dissolving Dosage Form. J Pharm and Pharmacol, 50:375-382.

- Anon. 1997. Flavors and Flavoring. Int J Pharm Compounding; 1:90-92.

- Schering Corporation. Product Information for Claritin Brand of Loratadine. September 2000.

- Tripathi KD. 2003. Essential Of Medical Pharmacology, 5th Edition. New Delhi: Jaypee Brothers Medical Publishers (P) Ltd, p 264-276.

- Synder Ann K.2004. Diabetes Mellitus and Glucose Regulation. Mar 29, Office: 2.177, 578-8804.

- Wilson Griswold’ S. 1999. Text Book Of Organic Medicinal and Pharmaceutical Chemistry, 9th Edition. Philadelphia: JB Lippincott Company, p 579.

- Singh Harkishan, Kapoor VK. 2001. Medicinal and Pharmaceutical Chemistry, 1st Edition. Delhi: Vallabh Prakashan, p 320-321.

This work is licensed under a Creative Commons Attribution 4.0 International License.