How to Cite | Publication History | PlumX Article Matrix

Potential of Biomass Cogeneration Marine System Powering

O. O. Sulaiman1, A. H. Saharuddin1, A. S. A. Kader1 and K. B. Samo2

1Department of Maritime Technology, University Malaysia Terengganu, Malaysia.

2Department of Marine Technology, University Teknologi Malaysia Malaysia.

orresponding Author E-mail: O.Sulaiman@umt.edu.my

ABSTRACT: Waste disposal from ships is becoming an increasing problem in today’s society. Thus various ways are being promoted to minimize, re-use and recycle waste streams there will always be residual wastes in a safe and beneficial way. The classification of fuels derived from waste sources as sustainable is controversial especially when it is linked to carbon cycle and food. The processing of these waste types, by various means, to provide fuels for electricity and heat generation, and transportation fuels, can provide many environmental advantages in term of energy production that lead to vast reduction in the waste stream, production of valuable byproducts, waste land reduction and the killing of the pathogens and bacteria that cause disease. The process can be more sustainable by using hybrid cogeneration biomass system for marine system. This paper will consider how enormous waste from ship and port and discuss potential of hybrid biomass cogeneration for marine system for port powering.

KEYWORDS: Alternative energy; sustainability; hybrid; port; power; energy; bio-derived

Download this article as:| Copy the following to cite this article: Sulaiman O. O, Saharuddin A. H, Kader A. S. A, Samo K. B. Potential of Biomass Cogeneration Marine System Powering. Biosci Biotechnol Res Asia 2010;7(2) |

| Copy the following to cite this URL: Sulaiman O. O, Saharuddin A. H, Kader A. S. A, Samo K. B. Potential of Biomass Cogeneration Marine System Powering. Biosci Biotechnol Res Asia 2010;7(2). Available from: https://www.biotech-asia.org/?p=8822 |

Introduction

Green house gas (GHG) pollution is linked to energy source. Large amount of pollution affecting air quality is prone by reckless industrial development. For years, many think that everything that run into the trio of nature, the atmosphere, ocean and soil is infinite. The atmosphere and the ocean that is providing us source of freshening, winds and current are far more vulnerable to polluting activities from manmade energy sources that have run off into them too many poisons that the air, the ocean and land may cease to serve more purpose if care is not taking to prevent pollution affluence. Human activities are altering the atmosphere, and the planet is warming. It is now clear that the costs of inaction are far greater than the costs of action. Aversion of catastrophic impacts can be achieved by moving rapidly to transform the global energy system.

Sustainability requirement that can be solved through energy conservation (cf. IPCC 2007: 13) are energy and associated efficiency, development, environment, poverty. Stakeholder from government’s consumers, industry transportation, buildings, product designs (equipment networks and infrastructures) must participate in the decision work for sustainable system. Recently the marine industry is getting the following compliance pressure regarding environmental issues related to emission to air under IMO MARPOL Annex 6. A world without port means a lot to economy transfer of goods, availability of ships and many things. Large volume of hinterland transportation activities import tells a lot about intolerant to air quality in port area. Adopting new energy system will make a lot of difference large number of people residing and working in the port. Most port facilities are powered by diesel plant. Integrating hybrid of hydrogen and solar into the existing system will be a good way for the port community to adapt to new emerging clean energy concept [1, 2].

The search for new source of energy to mitigate threat of climate change is becoming an urgent matter. New knowledge and technology have emerged. and race is on for the choice of the best. Ports of the world collect massive waste from the ship and oil platform. There is no drain in this planet; the waste got nowhere to go, but to return back to the system with consequential environmental damage, contamination of rivers, estuarine and the ocean and landfill and associated degradation as well as cost treatment. The greatest challenge for humanity lies in recycling waste for production of energy.

Sources of alternative energy are natural. There has been a lot of research about the use of free fall energy from the sun to the use of reverse electrolysis to produce fuel cell. For one reason or the other these sources of energy are not economical to produce. Most of the problems lie on efficiency and storage capability. Early human civilization use nature facilities of soil, inland waterways, waterpower which are renewable for various human needs. Modern technology eventually replaces renewable nature with non renewable sources which requires more energy and produces more waste. Energy, Economic and Efficiency (EEE) have been the main driving force to technological advancement in shipping. Environmental problem linkage to source of energy poses need and challenge for new energy source. The paper discuss risk based iterative and integrative sustainability balancing work required between the 4 Es in order to enhance and incorporate use of right hybrid combination of alternative energy source (Biomass, solar and hydrogen) with existing energy source (steam diesel or steam) to meet marine system energy demands (port powering).

Hybrid use of alternative source of energy remains the next in line for the port and ship power. Public acceptability of hybrid energy will continue to grow especially if awareness is drawn to risk cost benefit analysis result from energy source comparison and visual reality simulation of the system for effectiveness to curb climate change contributing factor, price of oil, reducing treat of depletion of global oil reserve. Malaysia tropical climate with reasonable sunlight fall promise usage of source of sun hybrid candidate energy, also hydrolysis from various components to produce fuel cell and hybridization with conventional system and combined extraction of heat from entire system seem very promising to deliver the requirement for future energy for ports.

This paper discuss available marine environmental issues, source of energy today, evolution of alternative energy due to the needs of the time and the barrier of storage requirement, system matching of hybrid design feasibility, regulations consideration and environmental stewardship. The paper also discusses holistic assessment requirement, stochastic evaluation, using system based doctrine, recycling and integrated approach to produce energy. With hope to contribute to the ongoing strives towards reducing green house gases, ozone gas depletion agents and depletion of oxygen for safety of the planet in order to sustain it for the right of future generation.

Energy, environment and sustainable development

Since the discovery of fire, and the harnessing of animal power, mankind has captured and used energy in various forms for different purposes. This include the use of animal for transportation, use of fire, fuelled by wood, biomass, waste for cooking, heating, the melting of metals, windmills, waterwheels and animals to produce mechanical work. Extensive reliance on energy started during industrial revolution. For years there has been increased understanding of the environmental effects of burning fossil fuels has led to stringent international agreements, policies and legislation regarding the control of the harmful emissions related to their use. Despite this knowledge, global energy consumption continues to increase due to rapid population growth and increased global industrialization. In order to meet the emission target, various measures must be taken, greater awareness of energy efficiency among domestic and industrial users throughout the world will be required, and domestic, commercial and industrial buildings, industrial processes, and vehicles will need to be designed to keep energy use at a minimum. Figure1 shows that the use of fossil fuels (coal, oil and gas) accounted continue to increase]. Figure 2 shows the contribution of total energy consumption in the by global region. And Figure 3 show natural gas consumption [2, 3].

|

Figures 1: GHG Emissions Reductions through 2050, by Consuming Sector.

|

|

Figure 2: World consumption of energy by region

|

![Figure 3: World consumption of natural gas [EIA, 2007].](https://www.biotech-asia.org/wp-content/uploads/2016/05/Vol_7_no2_Pote_Sula_fig3-150x150.jpg) |

Figure 3: World consumption of natural gas [EIA, 2007].

|

Various measures must be taken to reduce emission targets. The current reliance on fossil fuels for electricity generation, heating and transport must be greatly reduced, and alternative generation methods and fuels for heating and transport must be developed and used. Sustainable design can be described as system work that which enhances ecological, social and economic well being, both now and in the future. The global requirement for sustainable energy provision is become increasingly important over the next fifty years as the environmental effects of fossil fuel use become apparent. As new and renewable energy supply technologies become more cost effective and attractive, a greater level of both small scale and large scale deployment of these technologies will become evident. Currently there is increasing global energy use of potential alternative energy supply system options, complex integration and switching for design requirement for sustainable, reliable and efficient system. The issues surrounding integration of renewable energy supplies need to be considered carefully.

Current use of renewable energy

Most renewable energy development and supply are in small-scale, particularly on islands and in remote areas, where the import of energy sources through transport, pipeline or electricity grid is difficult or expensive. Individual buildings, industries and farms are also looking to the possibility of energy self-sufficiency to reduce fuel bills, and make good use of waste materials which are becoming increasingly difficult and expensive to dispose of Various studies have been carried out into the extensive use of new and renewable resources, to generate electricity, on a small scale, for rural communities, grid-isolated islands and individual farms. Recent studies focus on:

Security of supply: where consideration is given to intermittent sources, demand and supply must be as well matched as possible, and this is generally a function of climate. Available supply sources should be considered in order to find the best possible correlation between demand and supply.

Hybrid with conventional system: where energy limited sources used as spinning reserve for times when the intermittent supply does not meet the demand. If this type of spinning reserve is not available, the need for adequate electricity storage was shown to be an important consideration, especially in smaller scale projects.

Emerging renewable energy system

In order to provide a reliable electricity supply, reduce energy wastage, and enable the energy requirements for heat and transport to be met, the outputs of these intermittent sources may be supplemented by various means. These may include the use of storage devices and the use of biomass and waste materials in engines, turbines and fuel cells for the production of electricity and heat, in vehicles for transportation, or in heating supply or storage systems. The integration and control strategies for all of these components must be carefully considered and implemented, and this complexity has been seen as a barrier to renewable energy system deployment. There are many possible supply combinations that can be employed, and the optimum combination for a given area depends on many factors. The balances being considered can be complex, and this highlights the need for a decision support framework through which the relative merits of many different scenarios and control strategies for a chosen area can be quickly and easily analyzed [4,5].

The intermittent nature of most easily exploited sources of alternative energy remains the major problem for the supply the electricity network. This has implications for the management of this transitional period as the balance between supply and demand must be maintained as efficiently and reliably as possible while the system moves towards the ultimate goal of a 100% renewable energy supply over the next fifty to one hundred years. It important to take the of amount intermittent electricity sources that can be integrated into a larger-scale electricity supply network into consideration.

Excess supply could be supplied by plant run on fuels derived from biomass and waste. The renewable hybrid age require utilities, local authorities and other decision makers to be able to optimization that beat constraints, potentials, and other energy requirements from port powering. When intermittent electricity generating sources are used in a sustainable energy supply system, it is important to consider how well the profiles of demand and supply of electricity match. It is advisable to seek the best possible match by using varying amounts of a range of different intermittent sources. It is prudent to use as diverse a mix of generators as possible.

Where substantial amounts of intermittent sources are used in a system, it is useful to have an outlet for excess electricity, in order to avoid wastage. The electricity stored, using various means, depending on the scale of storage required can be available for use at times when there is not enough being generated to meet demand. The sizing and type of storage system required depends on the relationship between the supply and demand profiles. For excess amount electricity produced this could be used to make hydrogen via the electrolysis of water. This hydrogen could then be stored, used in heaters or converted back into electricity via a fuel cell later as required. Using excess electricity, this hydrogen could be produced centrally and piped to for port or produced at vehicle filling stations for haulage, or at individual facilities in the port. [6,7].

Energy consumption, demand and supply

Energy is considered essential for economic development, Malaysia has taken aggressive step in recent year to face challenges of the world of tomorrow, and this includes research activities strategic partnership. One example is partnership with the Japanese Government for construction on sustainable energy power station in the Port Klang power station, Pasir Gudang power station, Terengganu Hydro-electric power station and Batang Ai Hydro-electric power station which are main supply to major Malysian port. The above enumerated power stations are constructed with energy-efficient and resource-efficient technologies. Where power station are upgraded the power station by demolishing the existing aging, inefficient and high emission conventional natural gas/oil-fired plant (360MW) and installing new 750MW high efficiency and environment friendly combined cycle gas fired power plant built at amount of JPY 102.9 billion. Table 1 shows Malaysia energy and environmental data from EIA, and Table 2 shows energy outlook for Malaysia.

Table 1: Malaysia environmental review [EIA]

| Energy-Related Carbon Dioxide Emissions (2006E) | 163.5 million Metric tons, of which Oil (44%), Natural Gas (41%), Coal (15%) |

| Per-Capita, Energy-Related Carbon Dioxide Emissions ((Metric Tons of Carbon Dioxide) (2006E) | 6.7 Metric tons |

| Carbon Dioxide Intensity (2006E) | 0.6 Metric tons per thousand $2000-PPP**

96.0 billion kilowatt hours |

The combined-cycle generation plant is estimated to reduce the power station’s environmental impact, raise generation efficiency and make the system more stable. The total capacity of power generation of 1,500MW is equal to 14% of total capacity of TNB in peninsula of 10,835MW and indeed this power station is one of the best thermal power stations with highest generation efficiency in Malaysia of more than 55%. The rehabilitation, the emissions of Nitride oxide (NOx) is reduced by 60%, Sulfur dioxide (SO2) per unit is reduced by almost 100% and Carbon dioxide (CO2) emission is reduced by 30%. Port operation energy demands are for transportation, hot water and heat. This third generation plan can easily be integrated with alternative energy. Table 1 and 2 show Malaysia energy and environment outlook. And figure 4 show Malaysia energy consumption

Table 2: Malaysia Energy outlook [EIA, 2006]

| proven oil reservoir(January 2009) | 4 Billion barrels |

| oil production (2008) | 727, 2000 bbl/d, of which 84% is crude oil |

| oil consumption (2008) | 547,000 bbl/d |

| crude oil ldistilation capacity (January 2009) | 514,832 bbl/d |

| proven natural reserve (2007) | 83 trillion cubic feet |

| Natural gas production (2007) | 2.3 trillion cubic feet |

| Natural gas consumption (2007) | 1.2 trillion cubic feet |

| Recoverable coal reserves (2008) | 4.4 million short tons |

| Coal production (2007) | 1.1 million short tons |

| Coal consumption (2007) | 18.5 million short tons |

| Electricity Installed Capacity (2006E) | 23.3 gigawatts |

| Electricity Production (2006E) | 99.1 billion kilowatt hours |

| Total Energy Consumption (2006E) | 2.56 quadrillion Btu*, of which Natural Gas (35%), Oil (41%), Coal (15%), Hydroelectricity (2%) |

| Energy Intensity (2006E) | 99.4 million Btu per person |

| Total Per Capita Energy Consumption ((Million Btu) (2006E) | 8,891 Btu per $2000-PPP** |

Figure 2 shows the statistic of energy use in Malaysia. The energy use in all sectors has increased in recent years, most especially the energy use for transport has almost doubled it continues to grow and becoming problem. This trend is being experienced in industrialized and developing world.

|

Figure 4: Malaysia Natural gar production and consumption trend.

|

|

Figure 5: Malaysia Natural electricity consumption (EIA, 2007)

|

Energy demand for port work is supply from grids which are well established in most developed world. The method and sitting of generating conventional energy and renewable energy determine system configuration. Hierarchy systems that can be deduced from these two variables are:

Limited capacity energy: This includes traditional thermal plants coal fired, gas fired, oilfired and nuclear power plants, which supply almost all of the electricity to the national grid in. The amount of electricity that can be generated is limited by the physical capacity of the plant, time for maintenance and unplanned outages.

Limited energy plant: they are Renewable Energy Generators plant that are limited by the amount of energy or fuel available to them at a certain time from a certain area (e.g. rainfall, waste, seasonal energy crop yields) and cannot always run at their rated capacity.

Intermittent energy plant: recent year has seen increased hybrid generators. Growing distributed renewable generating plants has implications for the organisation of the electricity supply network. Interconnectivity network electrical system configuration. For centralized system it is better to have minor generators throughout the network that will allow many smaller areas of that network to become mainly self sufficient, with the grid stand as backup.

Fossil fuel use for transportation and port activities has increased dramatically over the past decade, and shows little signs of abating. This has caused concern about related environmental and health effects. There is need for to develop alternatively fuel system that produces little or no pollution. The main fuels that can be used in a variety of land, sea and air vehicles are biogas in natural gas and fuel cell vehicles, biodiesel in diesel vehicles, ethanol and methanol in adapted petrol and fuel cell. Biogas can be converted to run on natural gas and in some fuel cell. It must be cleaned first to create a high heating value gas (around 95% methane, a minimum of heavy gases, and no water or other particles).

Fuel cell powered engine can run on pure hydrogen, producing clean water as the only emission. Biodiesel can be used directly in a diesel engine with little or no modifications, and burns much more cleanly and thoroughly than diesel, giving a substantial reduction in unburned hydrocarbons, carbon monoxide and particulate matter. The main barriers to the implementation of alternative fuels is the requirement for a choice of fuel at a national level, the necessity to create a suitable refuelling infrastructure, the length of time it will take to replace or convert existing vehicles, and the need for a strong public incentive to change[3, 7, 8]..

Biomass demand and supply

Recent year has witnessed emerging trade on biofuel product between the US, EU, and Asia. Particularly South America, Brazil has already been branded to be producing en-mass ethanol from sugar cane since the 1970s with a cost per unit reportedly the lowest in the world. The top importers from US, EU, Japan and Korea have increasing demand that will have to be satisfied by increased shipping capacity. Also seaborne vegetable oil supply is increasingly growing. The EU imports 5.7 mt in 2001 and rise to 10.3 mt for 2008, an almost 50% of total capacity. Figure 2 show statistic of present food related biofuel, this reflect future food scarcity. Figure 1 shows the present global percentage of consumption for ethanol. Brazil exports the most ethanol globally at about 2.9 million tonnes per year [7,9].

Table 1a: World ethanol consumption 2007 [EIA]

| Region | Consumption |

| World ethanol consumption | 51 million tones, 2007 |

| US and brazil | 68% |

| EU and China | 17% – surplus of 0.1 million tones |

| US deficit | 1.7mt |

| EU deficit | 1.3 mt |

| World deficit | 1mt |

Table 2b: Biofuel growth [NREL]

| Biofuel source | Growth in 2008 | Gowth per annum |

| Vegetable oil | 33 mt in 2000 to 59 mt | 7.5% |

| Palm oil | 13 mt in 2000 to 32 mt | 8.9% |

| Soya bean | 7 mt to some 11.5 mt | 39% |

Bioenergy

The 21st century is becoming age of recycling where a lots of emphasize is placed on reducing waste and reuse of material to curb current environmental problems, maximizing use of depleting natural resources and conserve energy. Modern day sustainable use and management of resource recommend incorporating recycling culture in human ways and the use of modest process. Biomass is not left behind in this. The use of biomass energy resource derived from the carbonaceous waste of various natural and human activities to produce electricity is becoming popular. Biomass is considered one of the clean, more efficient and stable means of power generation. Enormous being generated from marine system make it imperative for marine industry to tap this new evolving green technology to employ mobile based micro generation biomass for mobile for marine energy system.

Advantage of biomass compared to other renewable based energy systems is that biomass can generate electricity with the same type of equipment and power plants that burn fossil fuels. Innovations in power generation of fossil fuels may also be adaptable to the use of biomass fuels. Also the ashes from biomass consumption, which are very low in heavy metals, can be recycled. Various factors notably have hindered the growth of the renewable energy resource, especially efficiency, likewise most biomass power plants operating today are characterized by low boiler and thermal plant efficiencies. Both the fuel’s characteristics and the small size of most facilities contribute to these efficiencies. In addition, such plants are costly to build. All in all, converting waste into fuel is beneficial even without a energy gain, if that waste will otherwise pollute the environment. Biomass has low sulfur content, this give biomass combustion advantage of less acidification than fossil fuel source.

Biomass remains potential renewable energy contributor to net reduction in greenhouse gas emissions and offsetting of CO2 from fossil generation. The current method of generating biomass power is biomass fired boilers and Rankine steam turbines, recent research work in developing sustainable and economic biomass focus on high-pressure supercritical steam cycles. It uses feedstock supply system, and conversion of biomass to a low or medium Btu gas that can be fired in combustion turbine cycles. It result in efficiencies of one-and-a-half times that of a simple steam turbine. Biofuels has potential to influence marine industry, and it as become importance for ship designers and ship owners to accept their influence on the world fleet of the future. Especially the micro generation concept with co generation for cargo and fuel can be a good biomass system for ship. And the waste being dumped by ships in port can be use to power land based and coastal infrastructure.

This paper discuss review of conceptual work, trend, sociopolitical driver, economic, development, risk approach and future of biomass with hope to bring awareness to local, national and multinational bodies making to adopt biofuels policies. The maritime industry is always slow to adopt new technology. The paper direct awareness call to maritime multidisciplinary expertise in regulation, economics, engineering, vessel design and operation to break the nity gritty barrier. Time has come for the shipping industry to take advantage of growing tide to tap benefit promised by use of waste to power generation for marine system.

Biomass developmental trend

The concept of using of Biofuels for energy generation has been existing for a long time. In the face of challenges posed by environmental need, the treat of climate change, pollution of water resources, and its growth is likely to dominate renewable energy market. The production and use of biofuels worldwide has grown significantly in recent years. Biofuels exist in solid, liquid or gas form, thereby potentially affecting three main core energy markets of materials. Solid biofuels or biomass is used in external combustion. Table 3 Shows trend in biomass development. Biomass use in use in the shipping

industry is limited to liquid biofuel due to lack of appropriate information, economics forecasts, sources of solid biomass include by-products from the timber industry,

agricultural crops, raw material from the forest, major parts of household waste, and demolition wood. All things being

equal using pure biomass that does not affect human and ecological food chain is suitable energy source for biomass.

The current world biofuels market is focused on: Bioethanol blended into fossil motor gasoline (petrol) or used directly and biodiesel or Fatty Acid Methyl Ester diesel blended into fossil diesel. The Fischer-Tropsch model involves catalyzed chemical reaction to produce a synthetic petroleum substitute, typically from coal, natural gas or biomass. It is used to runs diesel engines and some aircraft engines. The use as synthetic biofuel lubrication oil or aid synthetic fuel from waste seems promising and negates risk posed by food based biomass. Oil product and chemical tankers being constructed now are likely to benefit from the use of biomass. However use on gasoline engines ignites the vapors at much higher temperatures pose limitation to inland water craft as more oxide of nitrogen can be released to the atmosphere [10, 11].

Biomass developmental trend spillage to shipping

Just like tanker revolution influence on ship type, demand for biomass will bring capacity, bio – material change from source to production area to the point of use. Technological, environmental change will also require ships of different configuration, size and tank coating type as well as impact on the tonne mile demand. Recently biofuel is driving a new technology worldwide; the use of biofuels for cars and public vehicles has grown significantly. Effect on shipping is likely to be followed by shipping of large scale growth on exports and seaborne trade of biomass product from key exporting regions in order to balance supply and demand. With excess capacity waiting for source material it seems inevitable that shipping demand will increase.

Classification of biomass

According to generation types

Biomass generation and growing trend can be classified into 3 generation types:

First generation biofuels, are made from food like from sugar or starch, vegetable oil or animal fats to produce biodiesel.

Table3: Biomass development trend.

| Industry | progress |

| UK on June 2007 | First train to run on biodiesel went into service for a six month trial period. The train uses a blended fuel, which is Central. 20% biodiesel hybrid mix augmentation possibility to at least a 50% mix.

It has future possibility to run trains on fuels entirely from non-carbon sources.

|

| Argent Energy (UK) on 26th of October 2007. | UK buses running on B100 was launched

A UK pilot project where buses are run on B100 Argent Energy (UK) Limited is working together with Stage coach to supply biodiesel made by recycling and processing animal fat and used cooking oil for marine system. Limited is working together with Stagecoach to supply biodiesel made by recycling and processing animal fat and use of cooking oil for the pilot project.

|

| Ohio Transit Authority (COTA) on January 15, 2006 | Successfully tested a 20% blend of biodiesel (B20) in its buses wich eventually leads to approval of fleet wise use of biodiesel. In April 2006. COTA is working to use 50-90% biodiesel blends (B50 – B90) during the summer months. |

| US DOE development projects in 2001(Vermont project) | Funded five new advanced biomass gasification research and a

A projection for regular decrease of diesel fuel consumption by over one million gallons per year. |

| Ford on 2008, | Announce £1 billion research project to convert more of its vehicles to new biofuel sources. |

| BP Australia | Sold over 100 million liters of 10% ethanol content fuel to Australian motorists, and Brazil sells both 22% ethanol petrol nationwide and 100% ethanol to over 4 million cars. |

| The Swedish National Board for Industrial and Technical Development in Stockholm | Several Swedish universities, companies, and utilities, In 2008,Collaboration to accelerate the demonstration of the gas turbine natural-gas firing plant (0.6 megawatts of power output for a simple gas /.turbine cycle). It is a trend that is gathering momentum. |

| `AES Corporation

|

Recently completed a successful trial to convert the plant to burn a mixture of coal and biomass.

With further investment in the technology, nearly half of Northern Ireland’s 2012 renewable target could be met from AES Kilroot alone. |

| For power stations,

|

B&W have orders in the EU for 45 MW of two-stroke biofuel engines with a thermal efficiency of 51-52%. Specifically, these operate on palm oil of varying quality. |

Second generation biofuels, are waste derived biomass from agricultural and forestry, fast-growing grasses and trees specially grown as so-called “energy crops”.

Third generation biofuels, use green fuels like algae biofuel made from energy and biomass crops that have been designed in such a way that their s tructure or properties conform to the requirements of a particular bioconversion process.

According to sources types

North American Electric Reliability Council (NERC) region supply has classified biofuel into the following four types: agricultural residues, energy crops, forestry residues, and urban wood waste and mill residues. A brief description of each type of biomass is provided below:

Agricultural residues from the remaining stalks and biomass material left on the ground can be collected and used for energy generation purposes this include residues of wheat straw

Energy crops are produced solely or primarily for use as feedstocks in energy generation processes. Energy crops includes hybrid, switch grass grown on idled, or in pasture. The most important agricultural commodity crops being planted in the United States are corn, wheat, and soybeans represent about 70 percent of total cropland harvested. Thus, this is not encouraged to prevent food scarcity.

Forestry residues are composed of logging residues, rough rotten salvageable dead wood, and excess small pole trees.

Urban wood, waste and mill residues are waste woods from manufacturing operations that would otherwise be landfilled. The urban wood waste and mill residue category includes primary mill residues and urban wood such as pallets, construction waste, and demolition debris, which are not otherwise useful.

Biomass for electricity generation is treated in four ways in NEMS:

new dedicated biomass or biomass gasification,

existing and new plants that co-fire biomass with coal,

existing plants that combust biomass directly in an open-loop process, and

biomass use in industrial cogeneration applications. Existing biomass plants are accounted for using information such as on-line years, efficiencies, heat rates, and retirement dates, obtained through EIA surveys of the electricity generation sector.

Choice of conventional power system

Internal Combustion and Diesel Engines: Two common load following generation technologies involve the use of diesel in compression ignition engines (diesel engines), and natural gas in internal combustion engines (ICEs). Both of these engine types may also be run on sustainable fuels derived from biomass and waste, with diesel engines running on biodiesel, pyrolysis oil, or vegetable oil, and ICEs running on biogas, ethanol or methanol and this requires little or no modification. Diesel engine generating sets with rated outputs from 50 kWe to 10 MWe, and ICE generating sets with rated outputs of between 100 kWe and 2 MWe are available. Figure 6 shows diesel engine retrofit option towards reducing emission. Typically in the order of 2:1, and electrical efficiencies at full load are around 25 to 30%, again varying with partial load. Figure 6 shows a typical internal combustion engine.

|

Figure 6: Typical steam plant unit system.

|

Steam Turbines: Steam turbines may be used for larger applications (between 1 and 1000 MW). These use an external boiler to raise steam, which may be fuelled by any

type of solid, liquid or gaseous fuel desired..This steam is then expanded across turbine blades to produce rotary motion, and, when coupled with a generator, electricity]. Again, waste heat may be recovered for use. Figure 7 shows typical staem engine system Electrical efficiencies at full load can range from 15 to 50%, depending on the complexity of design. This means that heat to electricity ratios can vary from 1:1 to 5:1. This generation method is particularly suited to the use of large quantities of solid waste or biomass, provided suitable boilers are used, though start-up times are slow.

|

Figure 7: Steam engine system.

|

Stirling Engines: A Stirling engine is an external combustion engine, where combustion of the fuel does not take place inside the engine, but in an external boiler. Mechanical work is derived from the pressure changes that result from the cyclic heating and cooling of an enclosed working gas. Heat from any source may be used to run a Stirling engine, including concentrated solar rays, and waste heat but only fuelled Stirling engines will be considered here. This type of engine has many advantages over other engines and turbines as it allows the use of fuels that are hard to process, and it has a fairly simple design, which makes it suitable for small-scale applications, gives the plant a lower capital cost and reduces maintenance costs. Interest in Stirling engines is beginning to re-emerge due to increased interest in biofuel use. Currently available Stirling engine generating set outputs vary from 1 kWe to 200kWe, although larger engines are feasible. Figure 8 shows typical gas turbine engine.

Gas Turbines: Gas turbines may be run on biogas, and are available with rated outputs of between 3 and 50MWe. Their operation is based on the Brayton Cycle, where incoming air is compressed to a high pressure, fuel added to the air is burned to increase the gas temperature and pressure, and the resulting gases are expanded across the turbine blades, giving rotational movement. Coupled to a generator, this provides electricity generation, and waste heat may also be recovered for use. Figure 8 shows a typical gas turbine engine operation system.

|

Figure 8: typical gas turbine engine.

|

Choice of cogeneration alternative energy

Fuel Cells

The principle of the fuel cell was discovered over 150 years ago. NASA has improved the system in their emission free operation for spacecraft. Recent years has also seen improvement in vehicles, stationary and portable applications. As a result of this increased interest, stationary power plants from 200W to 2 MW are now commercially available, with efficiencies ranging from 30 to 50% and heat to electricity ratios from 0.5:1 to 2:1. Fuel cell re load follower energy, the efficiency of a fuel cell typically increases at lower loadings. Fuel cell system also has fast response. This make them well suited to load following and transport applications. Fuel cell is advanced alternative energy technology with electrochemical conversion of fuel directly into electricity without intermediate stage, the combustion of fuel; hence by-pass the restriction of second law of thermodynamic .the basic fuel supply in the fuel cell systems is hydrogen and carbon dioxide. The former has to be produced and feed in large quantity as pure hydrogen. Hydrogen is the lightest chemical element as demonstrated by the periodic table. Thus ,other lighter gas gases exist that can be use as fuel cell, but hydrogen offer greater energy per unit weight compare to other element candidate for alternative energy, and it is completely cyclic as it can be readily combined and decompose [9,10,11] . Table 3 shows types of electrolyte source for fuel cell energy.

2H2->4e- +4H+ (1)

4h+ +4e- +O2->2H20 (2)

2H2+02 -> 2H20 +Heat (3)

Table 3: Type of electrolyte fuel cell.

| Types | Electrolyte | Operating temperature |

| Alkaline | Potassium hydroxide | 50-200 |

| polymer | Polymer membrane | 50-100 |

| Direct methanol | Polymer membrane | 50-200 |

| Phosphoric acid | Phosphoric acid | 160-210 |

| Molten carbonate | Lithium and potassium carbonate | 600-800 |

| Solid oxide | Ceramic compose of calcium | 500-1000 |

Phosphoric acid fuel cell distribution: Fuel cell can be distributed directly through the following ways:

Direct supply to residential and commercial facilities through pipelines Modular cell that can be stack according to power need

Building hydrogen fuel cell power plant in remote location and distribute energy through power grid.

Comparing the efficiency of fuel cell to other source of alternative energy source, fuel cell is the most promising and economical source that guarantee future replacement of fossil fuel. However efficiency maximization of fuel cell power plant remains important issue that needs consideration for its commercialization. As a result the following are important consideration for efficient fuel cell power plant efficiency calculation can be done through the following formula fi9 shows a typical fuel cell power system:

G= H*T *Si (5)

Where: Ec=EMF, G =Gibbs function nF=Number of Faraday transfer in the reaction, H= Enthalpy, T=Absolute temperature, S=Entropy change i=Ideal efficiency

Advantages of fuel cell include size, weigh, flexibility, efficiency, safety, topography, cleanliness. Mostly use as catalyst in PAFC, and however recovery of platinum from worn -out cell can reduce the cost and market of the use of PACF economical. It has cost advantage over conventional fossil fuel energy and alternative energy. Disadvantages of fuel cell are adaptation, training, and cost of disposal. Fuel cell has found application in transportation, commercial facility, residential faculty, space craft and battery. Figure 9 shows a typical arrangement fuel cell hybrid power configuration.

|

Figure 9: Fuel cell hybrid configuration.

|

Solar energy system

History and human existent has proved that the sun is the source of all existing energy on earth. From plant photosynthesis to formation of biomass earth fossil fuel including oil and coal, to the generation of wind and hydrogen power, the sun has his mark on almost every planetary system. For decades, people have worked to generate renewable and cost saving solar energy. But little has been achieved to get a lot out f its abundant supply of sun light. Harnessing energy from sun require production, distribution, control and consumer utilization at low cost. Risk work for the system should address the back drop and hybrid system alternative energy system that can be installing as auxiliary for synchronization through automatic control system that activate storage supply whenever supply is approaching the minimum setup limit. Prior to installing solar, it is important to collect, analyze data and information to determined initial condition necessary to start the project and come with acceptable design. Such data should be use for simulation and construction of prototype model of the system that include existing system, central receiver, collectors, power conversion, control system, sunlight storage, solar radiation to supply a solar system to convert sunlight to electricity and distribute through existing channel.

Sola collector can be plate or dish type. Stefan` law relates the radiated power to temperature and types of surface:

![]()

Where P/A is the power in watts radiated per square meter, is surface emissivity, is Stefan-Boltzmann constant= 5.67x10e8 W/.

The maximum intensity point of the spectrum of emitted radiation is given by:

Hybrid system

With a focus on developing applications for clean, renewable, non-fossil fuel, energy systems. Our final emphasis is on maritime related activities, however, as marine engineers we are devoted to promoting all types of alternative & sustainable energy technologies.Various types of engine, turbine and fuel cell may be run on a variety of fuels for combined heat and power production. Hybrid system can provide control over power needs, green and sustainable energy that delivers a price that is acceptable and competitive. The power plants can be located where it is needed less high power lines are required, not only reducing costs but assisting health by reducing magnetic fields that people are so worried about, Global warming is addressed d by direct action by providing power that does not release any emissions or discharges of any kind. The technology associated with the design, manufacture and operation of marine equipment is changing rapidly. The traditional manner in which regulatory requirements for marine electrical power supply systems have developed, based largely on incidents and failures, is no longer acceptable. Figure 10 show a typical hybrid power arrangement for solar hydrogen and conventional power. Fifure 11 ,, 12, and 13 can be hybrid to the same sstem to provide integrated alternative energy power

|

Figure 10: Hybrid configuration

|

Current international requirements for marine electrical power supply equipment and machinery such as engines, turbines and batteries have evolved over decades and their applicability to new technologies and operating regimes is now being questioned by organizations responsible for the regulation of safety and reliability of ships. [7, 11].

Various technologies have been employed towards the use of alternative free energy of the sun since the first discovery in the 18th century. Improvement and development has been made towards making it available for use like existing reigning source of energy. Major equipment and hardware for the hybrid configuration are:

Semiconductor solar with high efficient storage capability will be designed

Hybrid back- up power will be design based with integrative capability to other alternative power source like wind and hydrogen

Controller design for power synchronization will be designed and prototyped

Inverter and other power conversion units will be selected based on power needs

Solar collector or receiver with high efficiency collection capacity will be designed

Software development and simulation

Steam will be used as energy transfer medium

The power plants can be built in small units combined, which allow greater control over the output and maintains full operational output 100% of the time. The plant produces fewer emissions, the plant can be located close to the areas where the power is required cutting down on the need for expensive high power lines. Excess energy produced can be connected to the grid under power purchase arrangement.

|

Figure 11: Biogas hybrid.

|

|

Figure 12: Fuel cell hybrid.

|

The system can be built in independent power configuration and user will be free from supply cut out. In a typical off-grid scenario a large battery bank is required to store energy. Solar hydrogen hybrid energy is stored in the form of hydrogen gas. When it is dark out, instead of drawing energy from a battery bank,

hydrogen gas is converted into electricity through a fuel-cell. Likewise, during the day when there is plenty of energy from the sun, water is converted into hydrogen gas through the use of a hydrogen generator. Most electrical power systems are a combination of small units of power group to provide the larger output.

Hybrid system design should begin with problem definition of providing a port with power, follow by refining the design so that each individual units power output could be combined to provide the input for a larger unit and ensure efficient, effect operation, maintenance. The hybrid system should be able to provide more power that can keep the stress and strain of operation to a minimum and reduces the failure of the component parts. The system should be designed with built in redundancy to compensate for failure of a component. The system has advantage of maintenance that can be carries out while keeping the system delivering the full capacity as well as alternation of delivery devices to extend their operational life. Figure 11 sj

|

Figure 13: Typical hybrid system (USMMA, 2008)

|

One of the unique features of hybrid system is the sustainable, clean energy system that uses a hydrogen storage system as opposed to traditional battery. Its design construction and functionality are inspired by the theme of regeneration and the philosophy of reuse. High efficiency solar panels works with an electrolyser to generate the hydrogen for fuel cell. The system can universal solar energy for marine application and other energy application as needed in equal capacity to existing fossil power plants.

|

Figure 14 shows a typical control system arrangement for the switching.

|

|

Figure 15: Bio energy usage projection [DOE, 2008]

|

The hybrid system can provide means to by- pass and overcome limitation posed by past work in generating replaceable natural energy of the sun and other renewable energy source that can be designed in hybrid system. Reliable deployment of hybrid system developments of mathematical model follow by prototyping, experimentation and simulation of the system are key to the design and its implementation. The main advantages of hybrid configurations are: Redundancy and modularity, high reliability of hybrid circuitry embedded control system, improve emergency energy switching and transfer, low operating cost through integrated design, low environmental impacts due to nature of the energy source. System optimization with combined heat and alternative power production technologies:

The Production and Storage of Heat

Space Heating Storage Heaters

Hot Water Storage

Instantaneous Space and Water Heaters

Uses for Excess Electricity

Electricity Storage Devices

Time has gone when maritime industry could not afford nitty gritty in adopting new technology, other industry are already on a fast track preparing themselves technically for evitable changes driven by environmental problem, global energy demands and political debate that add pressures to find alternative energy especially bio energy. The implication is that shipping could be caught ill prepared for any rapid change in demand or supply of biofuel. Thus this technology is in the early stages of development but the shipping industry need to be prepared for the impacts of its breakthrough because shipping will eventually be required at the centre of this supply and demand logistics chain. System integration hybridization of old and new system offers advantage for require change. Figure 15 and show the regional projection for biofuel usage and demand for the US and Europe which are the current main user in future.

Potential impacts to marine system

Impact to marine system

The use of biofuels as a fuel has increased in most transportation sectors. Adopting this technology in marine industry is still slow despite flexibility offered by use of energy on ship compare to mass requirement for land based industry and ambient temperature performance for aviation industry. Cost remain one of the main driver, slow speed diesel engines can run on lower quality fuels, they can replace distillate marine oils associated technical difficult. Calorific energy value for main propulsion could also result in a reduced service speed, range or larger bunker tanks. Major benefit of using environmental friendly engine is illustrated in figure 16.

|

Figure 16: benefit of using environmental friendly engine.

|

Potential for port coastal and port infrastructure: A variety of methods could turn an age-old natural resource into a new and efficient means of generating electricity. Biomass in large amounts is available in many areas, and is being considered as a fuel source for future generation of electricity. Biomass is bulky, widely distributed and electricity from conventional, centralized power plants requires an extensive distribution network. Traditionally power is generated through centralized, conventional power plant, where biomass is transported to the central plant. Typically a steam or gas turbine power plant and the electricity is then distributed through the grid to the end users. Costs include fuel transportation, power plant construction, maintenance operation, and distribution of the electric power, including losses in transmission. This is system is ideal for coastal and port infrastructure marine system powering. Table 4 shows efficiency comparison between coal and biomass..

Table 4: Efficiency comparison [EIA]

| Electrical efficiency | Capacity | |

| Biomass | thermal

efficiency-40 % |

$2,000 per kilowatt

|

| Coal | 45 % | $1,500 per kilowatt, |

Potential for ship and offshore system

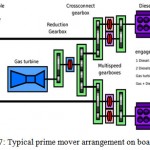

Micro-biomass power generators seem to offer a path for new solution for energy at end user disposal. Recent development towards use of micro biomass can offer best practice adaptation for marine unitized biomass power. Such biomass can be used near the site of end-use, with heat from external combustion converted directly to electricity by a biomass fired free-piston genset. Costs of installation include fuel acquisition and maintenance of the genset and burner. Since the electricity is used on site, both transmission losses and distribution costs are minimal. Thus, in areas without existing infrastructure to transmit power, there are no additional costs. It is also possible to cogenerate using the rejected heat for space or hot water heating, or absorption cooling. This is ideal for ship and offshore system. Figure 17 shows typical prime mover arrangement for ship

|

Figure 17: Typical prime mover arrangement on board ship.

|

Micro-biomass power generation is a more advantageous and cost-effective means of providing power than centralised biomass power generation. Especially in area where there is a need for both power and heating. Domestic hot water, space heat and absorption chilling are attractive for cogeneration configurations of microbiofuel plant. Biomass can be generated using single or ganged free-piston Stirling engines gensets. They can be placed at the end-user location taking advantage of local fuel prices and do not require a distribution grid. They can directly provide electrical output with integral linear alternators, or where power requirements are larger they can be connected in series and parallel to drive a conventional rotary turbine. They are hermetically sealed and offer long lives through their non-contact operation [12,13].

Emissions offsets and waste reduction could help enhance the appeal of biomass to utilities. An important consideration for the future use of biomass-fired power plants is the treatment of biomass flue gases. Biomass combustion flue gases have high moisture content. When the flue gas is cooled to a temperature below the dew point, water vapor starts to condense. By using flue-gas condensation, sensible and latent heat can be recovered for district heating or other heat consuming processes. This increases the heat generation from a cogeneration plant by more than 30 percent. Flue-gas condensation not only recovers heat but also captures dust and hazardous pollutants from flue gases at the same time. Most dioxins, chlorine, mercury, and dust are removed, and sulfur oxides are separated out to some extent. Another feature of flue gas condensation is water recovery, which helps solve the problem of water consumption in evaporative gas turbines.

Biomass is a substantial opportunity to generate micro-biomass electric power, at power levels from fractions of kilowatts through to tens or hundreds of kilowatts, at the point of end use. Neither small internal combustion engines, which cannot use biomass directly, nor reciprocating steam engines, with low efficiency and limited life, can offer the end user economic electric power. Free-piston Stirling micro biomass engine are an economic alternative. Stirling offers the following advantages over significantly larger systems:

Stirling machines have reasonable overall efficiencies at moderate heater head temperatures (~600ƒC)

cogeneration is simple

large amounts of capital do not have to be raised to build a single evaluation plant with its associated technical and economic risks

A large fraction of the value of the engine alternator can be reused at the end of its life

Stirling systems can be ganged with multiple units operating in parallel.

Biodiesel machinery design, installation, operation

and maontaonace requirements are:

Fuel management: Fuel management is complex in this new era because fuel aging and oxidation can lead to high acid number, high viscosity, the formation of gums and sediments. Supply chain supply of biofuel to ship can be done through pre-mixed to the required blend. Here the biofuel and diesel are supplied separately to the ship, and then mixed on board. This gives the operator the chance to dictate the exact blend of biofuels depending on conditions. But that would require retrofitting or new technology to be installed on board together with additional complexity for the crew. It is also important to monitor the fuel acid number value to ensure that no rancid, acidic fuel is introduced to the injection system. A typical layout should involve separators to ensure that water is removed from the fuel, as well as heaters at various stages to ensure the fuel is at the correct temperature before they enter engine.

Temperature monitoring system: Technical problem that need to be further mitigated is the CFPP indication of low temperature operability of range between 0°C and 15°C for different types of biodiesels. This can cause problems with filter clogging, this can only be overcome by carefully monitoring of the fuel tank temperatures. This can affect ships operating in cold climates, where additional tank heating coils and heating may be required to avoid this from happening.

Corrosion control: Biodiesels are hygroscopic and require to be maintained at 1200-1500 ppm water, which can cause significant corrosion damage to fuel injection systems. Mitigation can be exercise through appropriate fuel conditioning prior to injection. Biodiesels. Injector fouling especially the blend type produces deposits due to presence of fatty acid and water in the fuel. This can result to increased corrosion of the injector system. Also viscous glycerides can contribute to further injector coking. Biodiesel due to its chemical properties degrades, softens or seeps through some gaskets and seals with prolonged exposure. Biodiesels are knows to be good solvents and therefore cause coating complexity. Reports of aggressiveness of biodiesel and bioethanol on tank coatings have been reported. In its pure form biodiesel, as a methyl ester, is less aggressive to epoxy coatings than ethanol. Therefore ethanol should be carried in tanks coated with dedicated tank coatings such a phenolic epoxy or zinc silicate tank coatings.

Lubrication: Biofuel lubricant may have impact on engine crankcase cleanliness and the potential consequences of fuel dilution. The droplet characteristics and lower volatility of biodiesel compared with conventional diesel, together with spray pattern and wall impingement in the modern diesel engines, can help noncombusted biodiesel past the piston rings. And also to make contact with the cylinder liner and be scrapped down into the oil sump. The unburnt biodiesel tends to remain in the sump and the level of contamination may progressively build up over time. This can result in reduced lubricant viscosity and higher risk of component wear. A serious concern is the possibility that the unburnt biodiesel entering the oil sump may be oxidised, thus promoting oil thickening and requiring greater oil changes.

Impact to shipping

It is clear that biomass will fuel freight increase as well asspecialized new design of chemical tankers. Biodiesel is an IMO 2 cargo, its vegetable oil feedstocks are IMO cargoes with double hull IMO 3 vessel configuration required. Ethanol typically transports in chemical tankers due to its cargo requirement but technological change break through could bring potential regulatory design change. Flexibility for ship conversion and retrofitting system could upset initial cost problem.

Port, Inland waterways and coastal vessel

There is potential for us of biodiesels for small craft that operate within inland water because of air and water pollution sensitivity associated with inland water transportation. The port facilities in Malaysia and Indonesia are already being improved to handle Handysize and Panamax tankers. There is also potential requirement for transshipment and supply vessel, supply chain for short sea service.

Cargo

3rd generation biofuels wil required to be processed from solid cargoes to liquid cargoes. Of the wood currently harvested, 30% is waste. This is not going to be a waste in the future and will be converted by a Fischer Tropsch biomass to liquid processing plant. For coastal shipping to handle this trade, there wil be need for new generation of 5,000 tonne deadweight dry cargo vessels. It is expected that these voyages will be regulated under the new Dry Bulk Cargo Code (BC Code). This is due to become mandatory in 2011.

Shipping Routes and Economics Impacts

The above trend analysis discussed indicate potential capacity requirement from shipping. so far North America, Europe and South East Asia are the key importing regions where this growth is concentrated. Latin American counties of Brazil, Argentina, Bolivia, and Paraguay and Southeast Asia’s Indonesia and Malaysia will remain key suppliers for the palm oil, Philippines and Papua New Guinea have potentials for vegetable oil and agricultural while Thailand has potential for sugarcane.

Table 5: Regional impact [EIA]

| Biofuel | Demand | |

| North America | Ethanol | 33 million tons |

| Europe | ethanol and biodiesel.: 50:50 | 30 million tons |

| Asia | ethanol and biodiesel.: 50:50 | 18 million tons |

Regulatory framework impact

In many parts of the world, environmental concerns are the leading political driver for biofuels. This driving force evolved regulation like Kyoto protocoal, Marpol Annex VI and other environmental regulation. The tonne mile demand for future tankers will be greatly affected by national, regional, global policy and political decision making. There is a greater flexibility in the sourcing of biofuels than there is in hydrocarbon energy sources and this may be attractive to particular governments. Once the regulatory framework is clear, economics will determine how the regulations will best be met and seaborne trade will be at the centre of the outcome.

Conclusion

The main challenge to use of biomass for power generation, therefore, is to develop more-efficient, lower-cost systems. Advanced biomass-based systems for power generation require fuel upgrading, combustion cycle improvement, and better flue-gas treatment. Future biomass based power. Generation technologies need to provide superior environmental protection at lower cost by combining sophisticated biomass preparation, combustion, and conversion processes with post combustion cleanup. Such systems include fluidized combustion, biomass integrated gasification, and biomass externally fired gas turbines. Ships life cycle is around 20- 25, for ship owners to make the most of the upcoming markets, it is necessary to be prepared for the new cargoes. Current ship designs may not be suited for biofuel ships. Therefore there is potential for pressure on organizations to adopt new standards to accommodate the demand driven by governmental legislation. This in itself has some risk involved, also the trade routes could create economy of large scale leading to larger ship production and sub sequential requirement from designer .Other evolving challenges to secure energy and environment are Fuel cell technology, nuclear, natural gas and fuels made from waste plastics.

Reference

- Sustainable Energy Ireland. “CO2 and Other Environmental Emissions Data” Table 7D, web site www.irish-energy.ie/publications/ index.html.

- M. K. Mann and P. L. Spath, “A Comparison of the Environmental Consequences of Power from Biomass, Coal, and Natural Gas”. Presentation at the Energy Analysis Forum. Golden, CO, May 29-30, 2002. web site www.nrel.gov/analysis/pdfs/m_mann.pdf.

- G. Wiltsee. “Lessons Learned from Existing Biomass Power Plants.” NREL/SR-570-26946 Golden, CO: National Renewable Energy Laboratory, February 2000. web site www.nrel.gov/docs/fy00osti/26946.pdf.

- Lane, N. W. and Beale, W.T. (1996a). “Stirling Engines for Micro-Cogen and Cooling. Proc Strategic Gas Forum”. Detroit M. June 19-20, 1996.

- R.L. Graham, B.C. English, and C.E. Noon, “A Geographic Information System-based Modeling System for Evaluating the Cost of Delivered Energy Crop Feedstocks” Biomass and Bioenergy, Vol. 18 (2000), pp. 309-329.

- M. J. Grubb. “The Integration of Renewable Electricity Sources”. Energy Policy. 1991. Vol. 19, No. 7.pp 670-688.

- F. R. McLarnon, E. J. Cairns, “Energy Storage”, Review of Energy, Vol. 14, pp 241-271.

- IMO, “Marine Environmental Protection Committee”. 44th session available at: http: www.imo.org/meeting/44.html, 2000.

- H. Lund, P. A. Ostergaard. “Electric Grid and Heat Planning Scenarios with Centralised and Distributed Sources of Conventional. CHP and Wind generation”. Energy 25. 2000, pp 299-312.

- D. McEvoy, D. C. Gibbs, J. W. S. Longhurst, “City-regions and the Development of Sustainable Energy Supply Systems”. Int. J. Energy Res. 2000, 24. pp 215-237.

- G. C. Seeling-Hochmuth, “A combined optimisation concept for the design and operation strategy of hybrid-PV energy systems”. Solar Energy. 1997. Vol. 61, No. 2. pp 77-87.

- R. Chedid, S. Rahman, “Unit sizing and control of hybrid wind-solar power systems”. IEEE Transactions on Energy Conversion. 1997. Vol. 12, No. 1. pp 79-85.

This work is licensed under a Creative Commons Attribution 4.0 International License.