How to Cite | Publication History | PlumX Article Matrix

M. K. Somda, Aly Savadogo, C. A. Tidiane Ouattara, A. Sidiki Ouattara and A. Sabad n dyo Traore

Centre de Recherche en Sciences Biologiques Alimentaires et Nutrititionnelles (CRSBAN). Universit de Ouagadougou Burkina Faso. Corresponding Author E-mail:somdasmarius@yahoo.fr

ABSTRACT: Analysis of four varieties mangos juice (Amelia, Brook, Wild, Zill) showed that their pulp contained an average 13.12 % (w/w) to 25.78 % (w/w) of total sugar and pH various to 3.61 to 5.20. The sugars were fermented with strains of yeasts isolated from wasted mangos. These yeasts belong to the Saccharomyces (S3) and Schizosaccharomyces (S1) genus. The pH and total sugars values decreased while alcohol increased with increasing period of fermentation. The mango juice fermented respectively with Saccharomyces and Shizosaccharomyces genus showed 12 % (v/v) and 5.5 % (v/v) of alcohol.

KEYWORDS: Biomass; pulp; sugar; yeast; fermentation; ethanol

Download this article as:| Copy the following to cite this article: Somda M. K, Savadogo A, Ouattara C. A. T, OuattaraA. S, Traore A. S. Production of Alcohol From Mango (Mangifera Indica L.) Using Saccharomyces and Schizosaccharomyces Genus Isolated From Wasted Mangos in Burkina Faso. Biosci Biotechnol Res Asia 2010;7(2) |

| Copy the following to cite this URL: Somda M. K, Savadogo A, Ouattara C. A. T, OuattaraA. S, Traore A. S. Production of Alcohol From Mango (Mangifera Indica L.) Using Saccharomyces and Schizosaccharomyces Genus Isolated From Wasted Mangos in Burkina Faso. Biosci Biotechnol Res Asia 2010;7(2). Available from: https://www.biotech-asia.org/?p=8802 |

Introduction

Burkina Faso and the others developing countries have long been with problems of processing and preservation of locally produced agricultural food products. The lack of solutions to these problems had led to enormous losses of the fruits harvest. Five thousand tones of mango (Magnifera indica L.) lossed per year in Burkina Faso (Fogue, 1998). Mango is a climacteric fruit and long distance transport is sometimes a problem. Latent fungal infections reported in mango are Alternaria alternata (Prusky et al., 1983), Colletotrichum sp. (Peterson, 1986), Dothiorella sp. (Johnson et al., 1991) and Fusarium subglutinans (Ploetz, 1994), which are present in the shoot tips and in different parts of the panicle even in the healthy ones; though, in lower density (Kumar, 1983). Anthracnose caused by Colletotrichum sp. is regarded as one of the single most significant production and post-harvest problem (Dodd et al., 1998). In West Africa, the tropical fruit like mango grow in abundance even in the wild (Aderiye et al., 1990). In this way the fruit apple is consumed to a considerable extent, however large quantities are usually wasted. One of the methods of processing and preserving mango is to ferment the mango juice, which has high carbohydrate content into alcohol like ethanol (Obisanya et al., 1987).

Good quality wines as well as acetic acid have been produced from a number of various mangos. But the composition of the available fermentescibles sugars and the acidity are critical factors which determine their suitability for alcohol production (Amerine et al., 1980). Also the mango juice is pasteurised and used for drinking.

The object of this study were to analyse the chemical compounds of four mango varieties and undertake the fermentation of mango juice into ethanol using locally isolated yeasts like Saccharomyces and Schizosaccharomyces genus from the wasted or crop mangos.

Material and Methods

Yeast culture

The yeasts were isolated by separating the cells coming from wasted mangos (Amelia, Brooks, Wild, Zill varieties).

These cells were thenstreaked on plates of malt extract agar (DIFCO) and yeast extract agar (DIFCO) and incubated at 26°C for 48hours. Pure cells were obtained after three further subcultures and microscopic analysis. The yeast strains were transferred and maintained at 4°C on Wickerham agar slants until needed (Obisanya et al., 1987).

Morphological and cultural characteristics

The morphological characteristics of the yeast were determined by microscopic examination after staining with crystal violet and methylene blue.

The cultural characteristics were studied on corn meal agar, potato dextrose agar and sodium acetate agar plates (Obisanya et al., 1987).

Physiological characteristics

Before each physiological study, the yeasts were subcultured twice on the Wickerham agar medium. Then inocula were grown aerobically in Erlenmeyer flasks containing the synthetic glucose medium contained per liter of waster distilled ( 3g (NH4)2SO4; 2g KH2PO4; 0.5MgSO4; 0.75g Na2HPO4 ; 3g Yeast extract and 20g Glucose); at 26°C on a rotary shaker at 150 rpm for 12h (Konlani et al., 1996).

Experiments on the effect of initial sugar concentration were conducted in 500ml flasks with 200 ml of synthetic glucose medium incubated at 30°C. On a rotary shaker at 150 rpm.

The initial glucose concentrations tested were 5, 10, 20 and 80 g/l. The carbon source was sterilized separately.

Cultures were monitored by sampling (10 ml) at the beginning of each experiment and after each hour of culture. In 10 ml of culture, the residual glucose and the cell biomass were determined before to analyse the yeasts growth kinetics parameters.

Residual sugars were determined as glucose by the colorimetric method using 3,6 dinitrosalicylic acids (DNS): 1 ml of diluted supernatant left after the separation of the biomass was mixed with 1 ml of dinitrosalicylic acid and heated to 100°C for 5 min.

The reaction was stopped in ice and optical density was read at 540 nm against a glucose standard graph (Miller, 1969).

Dry cell mass was determined gravimetrically. Cells were harvested by centrifugation with 10 ml of culture at 10.000 rpm for 10 min, at 25°C, washed twice with saline water (NaCl 9‰) and weighed after 24 h at 105°C (Konlani et al., 1996).

Preparation of mango juice

One hundred (100) mature, ripe and healthy mangos (Amelia, Brooks, wild, Zill varieties) were taken from four principles areas producers (Ouagadougou, Bobo-Dioulasso, Koudougou, Banfora) in Burkina Faso. The mangos were sorted, wasted and peeled manually using a clean knife. About 100g of the pulp (each variety) was blended with 500 ml of hot water in Kenwood blender. That gave 1:5 (pulp/ water) dilution. The slurry was filtered trough a double folded cloth to obtain the juice. Potassium metabisulphite at 0.1% (w/v) was added and the juice was pasteurised at 60°C for 3 min and stored in a freezer at 5°C until analysis.

Physico-chemical properties analysis from four varieties mangos juice

The pH for each sample (solution of matter quantity of mangos in liquid: 30 % w/v) was measured with a pHmeter standardised with acetate buffer pH4.0 according to AOAC method.

Moisture and ash were determined by oven drying respectively at 105°C and 550°C (AOAC, 1980).

Total sugars were estimated by phenol sulphuric acid method (Fox, 1991).

Fermentation of mango juice (Amelia)

The fermentation has carried on the mango juice and the synthetic glucose medium at 30°C for 21 days.

Microorganisms and inoculum preparation

Before each fermentation, four retained yeast were subcultured twice on the Wickerham agar medium and the inocula were grown aerobically in Erlenmeyer flasks containing the glucose medium at 26°C on a rotary shaker at 150 rpm for 24h.

Fermentation condition

The variety Amelia then Saccharomyces sp. (S3) and Schizosaccharomyces sp. (S1) genus were using for the fermentation experiment. Variety Amelia has been choised for it high level sugars contains. For the yeast choice their performance was assessed according to the fermentative potential based on the determination of the kinetic parameter (maximum specific growth speed) and specific production parameters (ethanol and cellular yields). The treated of ten aspirator bottles. Each bottle was seeded with 5% (v/v) of the 24h yeast inoculum separately Saccharomyces sp. (S3) and Schizosaccharomyces sp. (S1). The bottles were closed with rubber stoppers filted with fermentation locks containing an aqueous solution of 200 mg/l potassium metabisulphite. The mixture was incubated at 30°C for 21 days.

The pH and alcohol concentration were monitored daily during the fermentation. Racking was done for the fermenting juices when evolution of gas diminished at the end of primary fermentation.

The racked fermenting juices were transferred to clean sterile aspirator bottles with fermentation locks containing 250 mg/l potassium metabisulphite. Chemical changes were monitored at 7 days intervals until gas evolution stopped. The alcohol were transferred into bottles and stored in a refrigerator at 10 ± 2°C for alcohol stability. The same experiment is carried on the synthetic glucose medium.

Analytical methods

The pH was measured with a pH meter standardised with acetate buffer pH4.0 according to method AOAC. Ethanol was measured by gas chromatography (121 DFL -Intersmat) using 60/80 carbopack B, 15% Carbowax 20M glass column and a flame ionization detector.

The column temperature was 85°C and the carrier gas was nitrogen. Methanol was used as internal standard.

Results and discussion

Yeasts Characteristics

Global isolation has given twenties yeasts, but morphological and cultural characterization permit to retain four yeasts for the following study.

|

Figure 1a: Saccharomyces sp. cells.

|

|

Figure 1b: Schizoaccharomyces sp. cells.

|

The colonies have been isolated from wasted mangos.

The figures (1a, 1b) show the microscopic observation of strains yeasts belonging respectively to Saccharomyces and Schizoaccharomyces genus. The morphological and cultural characteristics of these yeasts are presented in Table1 below.

Table 1: Morphological and cultural characteristics of yeast strains.

| Yeast | Morphology | Pseudomycelium

formation |

Ascospores per

ascus |

Diameter of separate colony |

| S1 | Smooth edges colonies, creamy | Ovoid cells with extensive developed |

8 |

5 mm cells reproducing by fission |

| S2 | Separated edges colonies, creamy |

Extensive cells |

8 |

3 mm cells reproducing by fission |

|

S3 |

Smooth edges colonies |

Sparsely formed |

4 |

2 mm ellipsoïdal cells |

|

S4 |

Smooth edges colonies |

Extensive cells |

4 |

3mm spherical cells |

The morphological and cultural characteristics of the yeast isolated are presented in table 1.

Strains S1 and S2 formed eight ascospores per ascus, produced extensive mycelium and multiplied by fission. Both of strains S3 and S4 showed the following principal characteristics vegetative of spherical, ellipsoidal or cylindral cells by budding, production of sparse pseudomycelium after one week, and formation of four ascospores per ascus.

The morphological and cultural characteristics results found on strains S3 and S4 show according to Fowell (1969) probably their belong to Saccharomyces genus. Other reason of their appurtenance to Saccharomyces genus is flocculation ability according to Sree et al. (2000) and Nahvi et al. (2002). Strains S1 and S2 were identified as members of the Schizosaccharomyces because they formed eight ascospores per ascus and multiplied by fission (Obisanya et al., 1987).

yeast physiological characteristic

Table 2: Influence of initial glucose concentration (So) on the growth parameters of Saccharomyces sp (S3) and Schizosaccharomyces sp (S1).

|

Initial glucose concentration (g/l) |

Saccharomyces sp (S3) Schizosaccharomyces sp (S1) | ||||||||

| 5 | 10 | 20 | 80 | 5 | 10 | 20 | 80 | ||

| Biomass (g/l) | 1.60 | 2.60 | 4.44 | 8.92 | 1.43 | 2.11 | 3.08 | 6.87 | |

| Yx/s (g/g) | 0.36 | 0.28 | 0.24 | 0.13 | 0.28 | 0.20 | 0.19 | 0.08 | |

| Ye/s (g/g) | 0.25 | 0.32 | 0.35 | 0.46 | 0.18 | 0.27 | 0.29 | 0.39 | |

| Percentage of glucose used for biomass production (Xs) |

66 |

51.6 |

44.25 |

44.25 |

4.40 |

41.60 |

38.60 |

17.10 |

|

| µmax (h-1) | 0.25 | 0.35 | 0.34 | 0.20 | 0.32 | 0.35 | 0.37 | 0.15 | |

The results related to the influence of initial substrate concentration (So) on growth parameters of Saccharomyces sp (S3) and Schizosaccharomyces sp (S1) are presented in table 2. The maximum specific growth rate were respectively 0.35 h-1 and 0.37 h-1 on both yeasts and can be compared with 0.388 h-1 found by Neves et al. (2005) on the yeasts during wheat flour simultaneous saccharification and fermentation.

During the yeast strains test, the highest biomass yields per unit of glucose used (Yx/s) were observed at low concentration of glucose. An increase in substrate level from 5 to 80 g/l, the percentage of sugar used for production of cell biomass decreased whatever the yeast strain.

At the different glucose concentration tested both yeast strains (S1; S3) were unable to convert all the sugar into biomass. A portion of the sugar was transformed into ethanol. This phenomenon which occurred in good aeration conditions is called the Crabtree effect (Van Dijken and Scheffers, 1986) and could explain the present low cell yields compared with that of Candida utilis (0.5 g/g). A Crabtree negative yeast strain which does not produce any ethanol under sufficient oxygen supply at a glucose concentration of 20 g/l (Moss et al., 1969). The best biomass yield requires low glucose concentration condition (So).

Physico-chemical properties analysis from four mangos juice

Table 3: Physico-chemical properties of four mangos juice.

| Mangos used | pH | % Ash (g/g) | Moisture (w/w) | %Total sugars (w/w) |

|

Amelia (A) |

5.20 |

1.60 |

83.64 |

25.78 |

|

Brook (B) |

4.71 |

2.71 |

83.49 |

17.68 |

|

Wild(W) |

4.48 |

2.30 |

76.90 |

13.12 |

|

Zill (Z) |

3.61 |

2.05 |

81.22 |

16.76 |

The table3 shows the physico-chemical properties of four varieties mangos juice.

The pH values various from 5.20 to 3.61. Among these varieties; juice of Amelia variety was less acid. These findings were similar to those reported for African bush mango juice (Akubor; 1995) and other fruits like: banana and orange (Maldonado et al., 1975). The sugars proportions averaged 13.12 % (w/w) to 25.78 % (w/w) were highest than these reported by Akubor (1995) on African Bush mango juice. But it can be compare to the tropical fruits like banana, pineapple and orange which ranged between 4 % and 15 % (Maldonado et al., 1975). Concerning the ash content it various from 1.60 to 2.71 % was highest than the proportion found in bush mango. The ash contents the mineral elements which could be used by yeast to grow.

So these results obtained suggest that variety Amelia mango juice will produce a good quality alcohol (ethanol) and since the juice composition would have a remarkable effect on the alcoholic fermentation.

|

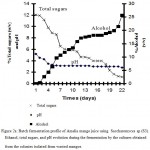

Figure 2a: Batch fermentation profile of Amelia mango juice using Saccharomyces sp (S3).Ethanol, total sugars, and pH evolution during the fermentation by the cultures obtained from the colonies isolated from wasted mangos. |

|

Figure 2b: Batch fermentation profile of Amelia mango juice using Schizosaccharomyces sp(S1).Ethanol, total sugars, and pH evolution during the fermentation by the cultures obtained from the colonies isolated from wasted mangos. |

Ethanol production during the mango (Amelia) juice fermentation

The fermentation profiles of yeast strains in mango (Amelia) are shown in Figure 2a to 2b.

Fermentation with Saccharomyces sp. resulted in total sugars decreasing from 25.78 to 9.9 % (w/v) in first 12 days, which corresponding to the primary fermentation period, but later decreasing to 2.5 % (w/v) over the next 21days. For yeast strains Schizosaccharomyces sp. The total sugar decreased from 25.78 to 12.6 % (w/v) in 12 days and decreased to less than over the following 21days. The yeast strains, which belong to the genus Saccharomyces, exhibited a higher fermentative rate than strains Schizosaccharomyces. These sugars were used for alcohol and organic acid production. This confirms the findings of Obisanya et al. (2007) that Schizosaccharomyces species ferment sugars at a rate of 50 % slower than Saccharomyces species.

The pH decrease respectively from 5.2 to 3.0 and 5.2 to 3.5 at the 14 th days with strains of Saccharomyces, and Schizosaccharomyces. Similar observations have been made for wine produced from African bush mango juice with Akubor (1995) while pH from 5.12 to 3.10. This decrease in pH was desirable as it helped to maintain the pH of the alcohol low enough to inhibit the growth of undesirable microorganisms.

Concerning the alcohol, it level increased from 0.5 to 8.5 % (v/v) and 0.2 to 6.2 % (v/v) at the end of the 14 days respectively for each strains of yeast. This level grows until to 12 % (v/v) for Saccharomyces and 6.4 % (v/v) for Schizosaccharomyces, although the fermentation juice left for 21 days. A noticeable growth of alcohol during Schizosaccharomyces fermentation at the 14 days is due to the utilisation of organics acid ( acid malic) to produce alcohol. This characteristic is typical of yeast of the genus Schizosaccharomyces according to Kunkee and Amerine (1970). The results obtained can be compare with Akubor (1995) experiment who found 8.5 % (v/v) of alcohol at 21th days.

Other author like Obisanya et al. (2007) reported 12% (v/v) alcohol produced on sugar with Saccharomyces sp. Sree et al. (1999) reported ethanol production by SSF of wheat products using Saccharomyces cerevisiae, which was 44.2 g ethanol/l.

As Lee et al. (1992) studied ethanol production using Zymomonas mobilis and slurries containing 100g/l of sago starch and found 40 g/l of ethanol. Some authors were able to obtain even higher ethanol production, such as 93 g/l or 140 g/l (Chi et al., 1999).

Acknowledgements

We thank The CRSBAN of Ouagadougou (Burkina Faso) for funding our studies on sugar-fermenting yeasts.

References

- AOAC, 1980. Official Methods of Analysis, 13th Edn. Association of official Analytical chemists, Washington, DC.

- Aderiye, B.I., M.A. Akpapunam and P.I. Akubor, 1990. Effect of fermentation variables on the quality of cashew wine. J. Agric. Sci. technol., 1(1): 16-69.

- Akubor, P.I., 1996. The suitability of African bush mango juice for wine production. Plant Foods for Human Nutri., 49: 213-219.

- Amerine, M.A., and C.S. Ough, 1980. Methods of analysis of musts and wine. In New York, John Wiley. P241

- Chi, Z., S.D. Kohlwein and F. Paltauf, 1999. Role of phosphatidylinositol (PI) in ethanol production and ethanol tolerance by a high ethanol producing yeast. J. Ind. Microbio. Biotech. 22:58-63.

- Dodd J.C., D. Prusky and P. Jeffris, 1998.Fruits diseases. In: Litz RE. The Mango-Botany, Production and Uses. (Eds.). Wallingford Oxon/CAB. International, pp: 257–280.

- Fogue, 1998. Technologie de séchage des fruits et légumes. Service d’appui aux PME (SAPE) ; CEAS Ouagadougou. Burkina Faso. 51p.

- Fowell, R.R., 1969. Life cycles in yeast. In the yeasts, Rose, A.H. and J.S. Harrison, 1: 303-383.

- Fox, J.D., and J.F. Robyt, 1991. Miniaturization of three carbohydrate analysis using a microsample plate reader. Anal. Bioch., 195: 93-96.

- Johnson, G.I., A.J. Mead, A.W. Cooke and J.R. Dean, 1991. Mango stem and rotpathogens-infection levels between flowering and harvest. Ann. Appl Biol., 119: 465–73.

- Konlani, S., J.P. Delgenes, R. Moletta, A.S. Traore and A. Do, 1996. Optimisation of cell yield of Candida Krusei S01 and Saccharomyces sp. LK3G cultured in sorghum hydrolysate. J. Bioress. Technol., 57: 275-281.

- Kumar J., 1983. Studies on symptomatology, etiology and control of mango malformation. Ph.D. Thesis, G.B. Pant University of Agriculture and Technology, Pantnagar.

- Kunkee, R.E. and M.A. Amerine, 1970. Yeasts in wine making. In The yeasts, Rose, A.H. and J.S. Harrison, (Eds.)s., London: Academic press, vol.3, pp:6-71

- Lee, C.G., C.H. Kim and S.K. Rhee, 1992. A kinectic model and simulation of starch saccharification and simultaneous ethanol fermentation by amyloglucosidase and Zymomonas mobilis. Bioprocess Eng. 7: 335-34.

- Maldonado, O., C. Roll, S.S. Cabrera and C.S. Schneider, 1975. Wine and vinegar production from tropical fruits. J. Food Sci., 40: 262-265.

- Neves, M.A., T. Kimura, N. Shimizu and K. Shiiba, 2005. Production of alcohol by simultaneous saccharification and fermentation of low-grade wheat flour. J. Zaffius Biotech. 1,(2):1-10.

- Miller, G.L.,1969. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31: 426–428.

- Moss, F.J.P., A.D. Richard, F.E. Bush and P. Caigen, 1969. The response by microorganism to steady- state growing controlled concentration of oxygen and glucose.

- Nahvi, I., G. Emtiazi and L. Alkabi, 2002. Isolation of flocculating Saccharomyces cerevisiae and investigation of its performance in the fermentation of beet molasses to ethanol. J. Biomass Bioenergy 23: 481–486.

- Obisanya, M.O., J.O. Aina and G.B. Oguntimein, 1987. Production of wine from mango

- (Mangifera indica L.) using Saccharomyces and Schizosaccharomyces species isolated from palm wine. J. of App. Bacteriol., 63: 191-196.

- Peterson, R.A., 1986. Mango diseases. Proceedings of the CSIRO First Australian Mango Research Workshop. pp: 233–247.

- Ploetz, R.C.,1994. Distribution and prevalence of Fusarium subglutinans in mango tree affected by malformation. Can. J. Bot., 72: 7–9.

- Prusky, D., Y. Fuchs, and U.Yanko, 1983. Assessment of latent infections as a basis for control of post harvest disease of mango. Plant Dis., 67:816–818.

- Sree, N.K., M. Sridhar, K. Suresh and L.V. Rao, 1999. High alcohol production by solid substrate fermentation from starchy substrates using thermotolerant Saccharomyces cerevisiae. J. Bioproc. Eng. 20: 561–563.

- Sree, N.K., M. Sridhar, K. Suresh, I.M. Banat and L.V. Rao, 2000. Isolation of thermotolerant, osmotolerant, flocculating Saccharomyces cerevisiae for ethanol production. Biores. Technol. 72 :43–46.

- Van Dijken, J.P., and W.A. Scheffers, 1986. Redox balance in the metabolism of sugars by yeasts. FEMS Microbiol. Rev., 32: 199-224.

This work is licensed under a Creative Commons Attribution 4.0 International License.