How to Cite | Publication History | PlumX Article Matrix

An Integrated Innovative Technology for the Treatment of Municipal Solid Waste Landfill Leachate

T. A. Trifonova, S. I. Roschina, L. A. Shirkin, O. G Selivanlov, M. E. Ilina

Vladimir State University by NG and AG Stoletovs, 600000, Vladimir, Gorkogo str., 87, Russia

DOI : http://dx.doi.org/10.13005/bbra/1927

ABSTRACT: The paper proposes an integrated innovative technology for the treatment of municipal solid waste landfill leachate, containing organic impurities resistant to oxidation and other toxic compounds. The developed process flow chart combines an advanced membrane technology with efficient developments of conventional wastewater treatment methods. In view of the complex multicomponent composition of municipal solid waste landfill leachate, it is proposed to use a modular approach to creating a process flow chart, which makes it possible to develop a leachate treatment technology for a specific MSW landfill, having the leachate with a specific qualitative composition. The development of this technology will make it possible to obtain purified water with characteristics, complying with the maximum allowable concentrations (MACs) for fishery water bodies.

KEYWORDS: municipal solid waste landfills; leachate; integrated innovative treatment technology

Download this article as:| Copy the following to cite this article: Trifonova T. A, Roschina S. I, Shirkin L. A, Selivanlov O. G, Ilina M. E. An Integrated Innovative Technology for the Treatment of Municipal Solid Waste Landfill Leachate. Biosci Biotechnol Res Asia 2015;12(3) |

| Copy the following to cite this URL: Trifonova T. A, Roschina S. I, Shirkin L. A, Selivanlov O. G, Ilina M. E. An Integrated Innovative Technology for the Treatment of Municipal Solid Waste Landfill Leachate. Biosci Biotechnol Res Asia 2015;12(3). Available from: https://www.biotech-asia.org/?p=4055> |

Introduction

In recent years the issues of wastewater treatment in Russia receive increased attention, as the prevention of harmful environmental effect and, consequently, adverse health effects thereof is one of the fundamental factors of the environmental safety strategy of a country. Among various environmental aspects of wastewater treatment, the task of the treatment of municipal solid waste (MSW) landfill leachate is brought to the forefront, which is related to the increasing input of wastes to MSW landfills. For instance, in Russia the volume of municipal solid waste, transferred to landfills, in 2013 amounted to about 49 million tons, while the volume of generated waste of all hazard classes every year is almost twice that of the volume of waste utilization and neutralization [1]. The process of steady accumulation of waste is underway. The situation with municipal solid waste utilization, neutralization and disposal remains unsatisfactory in most regions of Russia.

MSW landfills throughout their life cycle pose a significant epidemiological hazard, damage the natural landscape and are a source of contamination of soil, underground and ground waters, atmospheric air [2]. The most important factor of the negative environmental impact of MSW landfills is the formation of leachate in the body of a landfill, containing a variety of toxic chemicals, highly toxic chemical compounds, leached from waste and evolving in the process of biochemical decomposition of municipal solid waste.

Thus, reducing the negative impact of MSW landfills on the objects of the hydrosphere, including that caused by leachate, is a priority task.

The difficulties in developing leachate treatment technologies are related to the complexity of their compositions containing organic and inorganic substances, heavy metals, pathogenic microorganisms, etc., which determined an integrated approach to the development of leachate neutralization technologies using different treatment methods: mechanical, electro-chemical, physico-chemical, biological [3-5, 8-9].

The purpose of this paper is to develop an integrated technology for the treatment of MSW landfill leachate, containing organic impurities resistant to oxidation and other toxic compounds, using innovative treatment methods.

Research objects and methods

For the development of an integrated technology for the treatment of MSW landfill leachate, the leachate of the MSW landfills “Dmitrovsky” (the Moscow Region) and “Maryinsky” (the Vladimir Region) were selected as the objects of study.

MSW landfill leachate is highly contaminated and is characterized by high (hundreds of times higher than the maximum allowable concentration) content of toxic organic and inorganic substances, contains numerous products of dissolution of organic compounds – intermediate and final products of the processes of degradation of waste components, which determines its dark brown color and unpleasant smell. Such leachates contain organic components resistant to biological oxidation, for example, organohalogen compounds, nitrogen-containing organic complexes; therefore, they have very high values of chemical oxygen demand (COD), which can reach up to 40,000 mg O2/l. Their sanitary-epidemiological danger is exacerbated by the content of pathogenic microorganisms.

The basic characteristics of the untreated leachate of the landfills “Dmitrovsky” (the Moscow Region) and “Maryinsky” (the Vladimir Region) are presented in Table 1.

Table 1: Characteristic of the compositions of the untreated leachate of the MSW landfills “Dmitrovsky” and “Maryinsky”

| No. | Parameter, unit | Leachate of the MSW landfill “Dmitrovsky”

|

Leachate of the MSW landfill “Maryinsky”

|

| 1 | pH value | 8.3 | 7.4 |

| 2 | Total hardness, mg-equ/l | 26 | 18.0 |

| 3 | Alkalinity, mg-equ/l | 275 | 36.0 |

| 4 | Ammonia (NH4+), mg/l | 1,900 | 308 |

| 5 | Nitrates (NO3–), mg/l | 327.6 | 60.9 |

| 6 | Sulphates (SO42-), mg/l | 500 | 32.4 |

| 7 | Phosphates (PO43-), mg/l | 4.2 | 22.5 |

| 8 | Chlorides (Cl–), mg/l | 5,194 | 1,466 |

| 9 | Copper (Cu), mg/l | 0.063 | 0.237 |

| 10 | Nickel (Ni), mg/l | 0.016 | 1.172 |

| 11 | Iron (Fe), mg/l | 0.196 | 8.87 |

| 12 | Anionic surface-active substances (ASAS), mg/l | 28.4 | 11.4 |

| 13 | Nonionic surface-active substances (NSAS), mg/l | 93.5 | 37.5 |

| 14 | Oil products, mg/l | 150.9 | 15.76 |

| 15 | COD, mg O2/l | 9,434 | 2,400 |

| 16 | Permanganate demand, mg O2/l | 4,552 | 344 |

| 17 | Suspended solids, mg/l | 102 | 26 |

| 18 | Salt content, mg/l | 20,500 | 3,400 |

During the research on the development of technological modes, simulated solutions were also used, containing components, typical for MSW landfill leachate.

The analytical studies of the composition of the studied leachate, as well as of the leachate samples, taken at various stages of integrated treatment technology, were carried out according to the methods, included into the State register of the methods of quantitative chemical analysis and assessment of the state of the environment, approved for state environmental control and monitoring (PND F).

The pH of aqueous solutions was determined using the pH-meter/ion meter ECOTEST-120, the electrical conductivity was determined using the conductivity meter HM DIGITAL СОМ80. Anode corrosion rate was determined for tin and manganese using the atomic absorption method on the spectrometer MGA-915MD. The study of the anode surface relief was carried out using the scanning tunneling electron microscope Solver P 47H-PRO. The total microbial count (TMC) in water, purified and disinfected using UV radiation, was determined according to GOST 18963-73 “Methods of sanitary-bacteriological analysis”.

Results and discussion

The complex composition of MSW landfill leachate suggests the multi-stage treatment of seepage waters, comprising different stages. The study of individual stages of the treatment process and their combinations with the development of technological modes and norms was carried out using specially designed experimental facilities. In the process of conducting experimental research, the authors studied and proposed the following stages for the development of an integrated technology for the treatment of MSW landfill leachate, containing organic impurities resistant to oxidation:

- mechanical filtration;

- electrochemical oxidation;

- settling;

- ultrafiltration;

- reverse osmosis treatment;

- adsorption;

- ultraviolet disinfection.

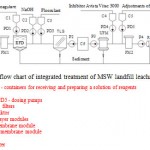

The process flow chart of integrated treatment of MSW landfill leachate is presented in Fig. 1.

|

Figure 1: The process flow chart of integrated treatment of MSW landfill leachate |

Each stage of the integrated technology is designed to solve the tasks of the extraction of impurity compounds from multicomponent aqueous solution, that is, from contaminated MSW landfill leachate.

At the first stage, polluted water undergoes mechanical filtration. MSW landfill leachate is characterized by increased colour index, turbidity and increased content of suspended solids. The nature of suspended solids in leachate can vary, but typically they include clay matter, sand, unoxidized organic particles including fat, etc.

The importance of mechanical filtration is that it, by performing the function of primary removal of undissolved impurities, eliminates many of the problems in addressing the subsequent tasks, greatly reducing the load on the following stages. In this technology it is proposed to use a mechanical self-cleaning strainer, which ensures the regeneration of filtering surface by the reverse current of water with the simultaneous use of special brushes, making it possible to remove contaminants from the the filtering surface of the strainer, wherein the operation of the strainer can also be automated.

A series of tests of the self-cleaning strainer, used to reduce the content of suspended solids in the leachate of the “Dmitrovsky” MSW landfill, was carried out. Table 2 shows the performance indicators of the strainer.

Table 2: The performance indicators of the self-cleaning strainer, obtained during the filtration of the “Dmitrovsky” MSW landfill leachate

|

No. |

Parameter |

Performance indicator |

| Water flow, supplied to the strainer, l/min | 60 | |

| Average filtration rate in a filtration cycle, l/min | 40 | |

| Specific filtration rate, l/m2 h | 9,500 | |

| Duration of a filtration cycle, min | 60 | |

| The volume of landfill leachate, passed through the strainer during the entire test, m3 | 9.5 | |

| Recovery of strainer performance to initial values after first washing, % | 100 | |

| Recovery of strainer performance to initial values after tenth washing, % | 99.8 | |

| Strainer regeneration time, sec | 7 | |

| Volume of water used for ten washes, l | 75 | |

| Retention potential of the strainer by suspended solids larger than 100 μm (tested after the first filtration cycle), % | 99.8 | |

| Retention potential of the strainer by suspended solids larger than 100 μm (tested after the tenth filtration cycle), % |

99.6 |

The operation of the strainer with combined filtration (100 μm filtration rating) during the mechanical treatment of MSW landfill leachate showed that this strainer ensures reproducible quality of filtration. After multiple washes the strainer performance is restored almost to initial values; the design of the strainer, having the built-in brushes in its housing, makes it possible to effectively clean the filtering screen from adhesive contaminants, typical for landfill leachate. The volume of water, required for washing the strainer, is not more than 1.5% of the total volume of water passed through the strainer during one filtration cycle, which doesn’t present a significant load on the water disposal system.

Thus, the use of the strainer in the developed technology is the optimal technical solution for the implementation of the stage of mechanical filtration in the system of primary treatment of municipal solid waste landfill leachate.

After the removal of mechanical impurities, MSW landfill leachate arrives at the electrochemical oxidation unit on the basis of an electroflotation destructor (EFD).

Currently, the electrooxidation of contaminating organic compounds, contained in water, is mainly implemented using ruthenium-titanium oxide anodes (RTOA), boron-doped diamond electrodes (BDDE), as well as Ti/PbO2 or Ti/SnO2 electrodes. As practice has shown, RTOA electrodes have low oxygen overpotential, which hinders the generation of hydroxyl radicals and, consequently, the mineralization of organic compounds resistant to oxidation; besides, they tend to corrode due to the release of oxygen. The preferred type of oxidation is that leading to complete mineralisation, i.e. to the formation of carbon dioxide, nitrogen, water and other easily removed substances. Complete mineralization takes place by means of direct anodic oxidation at the anodes with oxygen overpotential, such as BDDE [10], Ti/PbO2 or Ti/SnO2. Hydroxyl radicals, generated on these anodes, completely oxidize organic pollutants, contained in leachate. However, BDDE electrodes are subject to passivation [11] and are very expensive, lead dioxide coating does not have sufficient mechanical strength, and Ti/SnO2 anode is apt to corrosion, while also having insufficient anode oxidation efficiency [12].

Therefore, for the electrochemical oxidation of leachate it was proposed to use a specially designed nanocomposite Ti/MnO2–SnO2 anode with the size of SnO2 nanoparticles not exceeding 40 nm (Fig. 2).

|

Figure 2: Electronic photograph of the surface of the nanocomposite Ti/MnO2–SnO2 electrode |

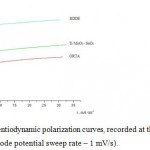

Fig. 3 shows anodic polarization curves of different anodes. As can be seen, the Ti/MnO2-SnO2 anode is intermediate in relation to the effectiveness of the anodic process. At i = 20 mA/cm2 the overpotential at the Ti/MnO2-SnO2 anode is 0.3 V higher than that of RTOA and 0.9 V less as compared to BDDE. However, the effectiveness of the oxidizing ability of the Ti/MnO2-SnO2 anode almost does not differ from that of BDDE and exceeds that of RTOA.

|

Figure 3: Anodic potentiodynamic polarization curves, recorded at the tested anodes in the leachate (electrode potential sweep rate – 1 mV/s) |

The conducted studies also demonstrated that the anode efficiency of the developed nanocomposite Ti/MnO2–SnO2 anode is almost 20% higher as compared to the Ti/SnO2 anode. Prolonged corrosion tests of nanocomposite Ti/MnO2–SnO2 anodes, carried out at the current density i = 80 mA/cm2 during 300 hours, showed that the rate of electrode corrosion doesn’t exceed 0.9 μm/year.

For the cathode it is proposed to use St12H18N9 steel with electrochemically precipitated nickel, having the thickness of a layer not exceeding 100 μm; it is known that cathode reduction of nitrate ions to free nitrogen takes place on nickel, which is very important in the leachate treatment.

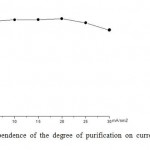

The degree of purification (DP) of leachate from organic compounds resistant to oxidation in an electroflotation destructor largely depends on the anodic current density (i). Fig. 4 shows the dependence of the degree of purification of leachate on current density at the same quantity of passed electricity (Q), equal to 6 A·h/l.

|

Figure 4: The dependence of the degree of purification on current density i, at Q = 6 A·h/l. |

At i < 5 mA/cm2 the increase of the degree of purification to 90% is observed, while within the range of current densities from 5 to 20 mA/cm2 the degree of purification doesn’t depend on the current density. At i = 5 mA/cm2 the electrode potential of the anode reaches 1.65 V, at which on the surface of the electrodes the formation of hydroxyl radicals takes place, which are the most powerful destructors of organic compounds resistant to oxidation.

Thus, the electrochemical oxidation of recalcitrant organic impurities of MSW landfill leachate in a flow electroflotation destructor using high-performance electrodes on the basis of nanocomposite materials ensures electroflotation extraction of colloidal particles, emulsified oil products and suspended solids, increases the degradation of organic matter resistant to oxidation, by means of direct oxidation, leading to almost complete mineralization, wherein the purification efficiency by COD reaches 90-95%. Oxidation is accompanied by partial conversion of ammonium nitrogen to nitrate nitrogen, by the reduction of water colour index and turbidity.

After the electrochemical oxidation the leachate enters the settling tank with thin-layer modules, where the process of clarification by means of sedimentation in the presence of coagulants and flocculants takes place (Fig. 5). As a coagulant in this technological scheme it is proposed to use a solution of ferric chloride (FeCl3) with the concentration of 10 mg/l, as a flocculant – a solution of Priestol 2640 (concentration of 0.2 mg/l).

|

Figure 5: Inclined settling tank from polymethyl methacrylate (PMMA) with honeycomb blocks having the height of 50 mm and the angle of inclination 600º |

A thin-layer module of the settling tank is a honeycomb structure made of PMMA sheets, with the cell size of 50 x 50 mm, wherein the thin-layer elements are set at an angle of 600º. The optimally designed system of the supply of untreated leachate and the absence of stagnant zones ensures the even distribution of the flow on the thin-layer sheets. The division of the free volume of the settling tank into small-sized cells contributes to the even distribution of water on the settling tank surface area, which increases the coefficient of volumetric use of the settling tank and the actual water residence time. The conducted studies demonstrated that when the suspension is supplied at the linear rate of 7-8 m/h, the selectivity of separation by suspended solids achieves 98.5%.

After the stage of settling the leachate arrives at the ultrafiltration membrane module, which uses a technology of immersion hollow-fiber ultrafiltration, proved to be efficient both in the treatment of natural and waste waters [13-16] and as a method of pre-treatment before the reverse osmosis stage.

This stage provides for a use of a thickener on the basis of immersion hollow-fiber ultrafiltration with continuous reverse flow washing without using automatic shut-off devices, with the application of a specially designed jerk pump. When a number of thickeners, installed in series, are used, it is possible to achieve the thickening of the suspension to the concentration of 40 g/l, which is 2-3 times higher than in case of using conventional ultrafiltration. Submersible membranes from polyvinylidene difluoride (PVDF) were used as membrane elements. The lifetime tests of membrane elements were carried out in different operation modes for the leachate of the “Dmitrovsky” landfill. The studies demonstrated that these membranes provide a high degree of purification – more than 99.9% by the suspended solids, degree of purification by COD – more than 29%, by colour index – 40%, by the content of nonionic surface-active substances – over 85%, while the ultimate performance of these membrane elements is 19-20 l/m2·h.

From the ultrafiltration membrane module the leachate arrives at the reverse osmosis membrane module. In this technological scheme it is proposed to use two-stage purification both for leachate and concentrate. The leachate of the first stage is further purified at the second stage to obtain the guaranteed quality of purified water, and the concentrate of the first stage is further concentrated at the second stage to reduce its volume. It is proposed to use a nylon membrane RE 4040SN as a membrane element. The combination of hydrophilic properties and neutral charge of the membrane surface reduces the adsorption of organic impurities, present in the leachate, and therefore ensures much lower propensity for fouling and pollution. At the same time the neutral charge of the membrane surface makes it possible to fully restore its performance characteristics. To increase the specific capacity of the membrane, the leachate is pre-acidified to pH = 7, and the inhibitor of the precipitation of hardness salts on the membrane surface Avista Vitec 3000 is added.

At the first stage of reverse osmosis the working pressure is 60 kgf/cm2, the degree of concentration K = 2.9, at the second stage the working pressure amounted to 15 kgf/cm2, the degree of concentration K = 9. Thus, after membrane reverse osmosis treatment purified water was received, corresponding to the requirements for the fishery waters.

In the developed technology for the integrated treatment of MSW landfill leachate the stage of sorption posttreatment is used to remove all traces of low molecular organic substances resistant to oxidation, remaining in the treated leachate after previous treatment stages. As an adsorbent it is proposed to use activated carbon Silcarbon k835 spezial (particle diameter 0.5-2.5 mm), having specific surface area 1100 m2/g.

At the stage of sorption posttreatment even lower values of ammonia nitrogen content and chemical oxygen demand are achieved, while the replacement of activated carbon filter bed takes place not more than once a year.

The stage of the disinfection of MSW landfill leachate after ultrafiltration and reverse osmosis is implemented using the flow ultraviolet sterilizer with a built-in ultrasonic sensor. Water is disinfected by ultraviolet radiation, generated by an amalgam bactericidal lamp. The minimum dose of UV radiation is 65 mJ/cm2.

The dependence of biochemical oxygen demand during the five days of incubation (BOD5) and the number of colony-forming units (CFU), characterizing the degree of bacterial contamination, on the leachate flow and the dose of UV radiation is shown in Table 3.

Table 3: The dependence of BOD5 and CFU on the leachate flow and the dose of UV radiation.

| Flow of | Dose of UV | Value of BOD5 in | Total microbial count, | ||

| leachate | radiation, | treated water, mg O2/l | CFU/100 ml | ||

| UV- | UV- | UV- | UV- | ||

| supplied to | mJ/cm2 | radiation | radiation + | radiation | radiation + |

| the plant, l/h | ultrasound | ultrasound | |||

| 1,000 | 65 | 3.0 | 2.5 | 50 | 41 |

| 750 | 80 | 2.5 | 2.0 | 43 | 35 |

| 500 | 130 | 2 | <2 | 37 | 30 |

| 450 | 145 | <2 | <2 | 25 | 22 |

| 350 | > 150 | <2 | <2 | 23 | 22 |

Thus, the combined technology “ultraviolet + ultrasound” with the radiation dose of 65 mJ/cm2 ensures the required quality of purified water and degree of disinfection of leachate, subjected to integrated fine purification, including reverse osmosis and sorption post treatment for the removal of low molecular organic substances. Joint use of ultraviolet radiation and ultrasound increases the efficiency of disinfection by an average of 20%.

A distinctive feature of the developed technology is the solution for the disposal of concentrates, which after ultrafiltration, the first stage of reverse osmosis, together with the sludge from the tank, are collected into the container for liquid waste and then returned into the body of the landfill, which excludes standard solutions for evaporation, combustion or condensation of liquid concentrates. In this case, the return of concentrates not onto landfill body, but into it, on the condition of certain technical characteristics of the return itself, has no negative impact on the biochemical processes taking place in the landfill body and does not increase the concentration of nontreated seepage waters (leachate).

Conclusion

- An integrated MSW landfill leachate treatment technology was developed, combining an advanced membrane technology with efficient developments of conventional treatment methods, which makes it possible to achieve the quality of treatment of MSW landfill leachate, complying with the requirements for water discharged into surface water bodies, according to the sanitary regulations and standards [17], ensure the environmental safety of MSW landfills, fully neutralize the environmental damage resulting from the pollution of surface and underground waters and soils, eliminate fines for discharging pollutants from the body of the landfill into water bodies and onto local terrain.

- On the basis of the developed technology it is planned to create a pilot mobile plant of a modular type for the treatment of MSW landfill leachate with the capacity of 5 m3/day, consisting of independent modules, which ensures considerable flexibility when developing a process flow chart for leachate treatment for a specific MSW landfill, having leachate with an individual composition. The individual stages of the developed technology and modular components may be used for the treatment of industrial wastewaters of a wide range of industries, having the sewage composition similar to the composition of landfill leachate and characterized by extremely high values of chemical oxygen demand (up to 40,000 mg O2/l).

The work was supported by the Ministry of Education and Science of the Russian Federation (Contract No. 02.G.25.31.066 of March 12, 2011).

References

- State Report “On the State and Protection of the Environment in the Russian Federation in 2013”, 2014. Date Views 22.12.2014 www.mnr.gov.ru.

- Zomarev, A.M., Ya.I. Vaysman, T.A. Zaitseva and I.S. Glushankova, 2010. Sanitary and Hygienic State of Municipal Solid Waste Landfills at Various Stages of Life Cycle. Hygiene and Sanitation, 1: 39-42.

- Gonopol’skiy, A.M., N.K. Nikolaykina, N.I. Mitashova, V.E. Murashov and K.Ya. Kushnir, 2008. A Multi-Stage Technology for the Treatment of Municipal Solid Waste Landfill Leachate. Water: Chemistry and Ecology, 2: 25-30.

- Konygin, A.A, L.S. Skvortsov and A.F. Seliverstov, 2010. Municipal Solid Waste Landfill Leachate Treatment. Water Supply and Sanitation, 1: 130-133.

- Pervov, A.G., 2009. History and Prospects of Application of Membrane Technology in Water Supply. Water and Sanitary Equipment, 7: 4-10.

- Povorov, A.A., N.V. Selivanova, T.A. Trifonova, V.F. Pavlova, O.G. Selivanov, M.E. Il’ina, L.A. Shirkin, V.B. Torshin, 2014. The Treatment of Municipal Waste Landfill Leachate. Proceedings of the Samara Scientific Center of the Russian Academy of Sciences, 1(16): 661-664.

- Trifonova, T.A., N.V. Selivanova, L.A. Shirkin, O.G. Selivanov and M.E. Il’ina, 2013. The Problems of Municipal Solid Waste Disposal in Landfills. Proceedings of the Samara Scientific Center of the Russian Academy of Sciences, 3(15): 685-687.

- Selivanova, N.V., T.A. Trifonova, O.G. Selivanov and V.Yu. Chukhlanov, 2014. Assessment and Treatment of MSW Landfill Leachate. International Journal of Applied and Fundamental Research, 8: 99-102.

- Polyakov, A.M., S.A. Solov’ev and M.N. Vidyakin, 2008. The Technology of a Membrane Bioreactor (MBR) for the Treatment of Natural Waters and Wastewaters. Critical Technology. Membrane, 3(39): 3-7.

- Pleskov, Yu.V., 2002. Electrochemistry of Diamond. Electrochemistry, 38: 1411-1422.

- Velegraki, Th., G. Balayiannis, E. Diamadopoulos, A. Katsaounis and D. Mantzavinos, 2010. Electrochemical Oxidation of Benzoic Acid in Water over Boron-Doped Diamond Electrodes: Statistical Analysis of Key Operating Parameters, Kinetic Modeling, Reaction By-Products and Ecotoxicity. Chemical Engineering Journal, 2(160): 538-548.

- Li, M., Ch. Fenq, Z. Zhang and N. Sugiura, 2009. Efficient Electrochemical Reduction of Nitrate to Nitrogen Using Ti/IrO2 – Pt Anode and Different Cathodes. Electrochimica Acta, 20(54): 4600-4606.

- Povorov, A.A., V.F. Pavlova, N.A. Shinenkova and O.Yu. Logunov, 2009. Landfill Leachate Treatment Technology. Municipal Solid Waste, 4: 26-27.

- Stalinskiy, D.V., S.I. Epshtein, Z.S. Muzykina and I.S. Varnavskaya, 2012. An Integrated Approach to Solving the Problem of Municipal Solid Waste Landfill Leachate Treatment. Water Treatment, 4: 7-14.

- Judd, S., 2006. The MBR book, Principles and Applications of Membrane Bioreactors for Water and Wastewater Treatment. Elsevier.

- Zheng, X., Y. Zhou et al., 2010. Survey of MBR Market: Trends and Perspectives in China. Desalination, 2: 609-612.

- Sanitary Regulations and Standards SanPiN 2.1.5.980-00 “Municipal Wastewater Disposal, Sanitary Protection of Water Bodies. Hygienic Requirements for the Protection of Surface Waters”, 2000.

This work is licensed under a Creative Commons Attribution 4.0 International License.