How to Cite | Publication History | PlumX Article Matrix

Surface Modification to Reduce Deposition Flux of Spray Dried Noni (Morinda Citrofolia L.) Juice

Noraziani Zainal Abidin, Saiful Irwan Zubairi  and Haslaniza Hashim*

and Haslaniza Hashim*

Centre for Biotechnology and Functional Food, Faculty of Science and Technology, Universiti Kebangsaan Malaysia, 43600 UKM Bangi, Selangor

Corresponding Author E-mail: haslaniza@ukm.edu.my

DOI : http://dx.doi.org/10.13005/bbra/2790

ABSTRACT: Spray drying is widely spread technique for drying of liquid products especially fruit juices such as noni juice. However, during spray drying of noni juice stickiness problem commonly occurs due to low molecular weight sugars (sucrose, glucose and fructose). The aim of the present research was to determine the impact of Teflon surface modification on the yield of spray dried Noni juice and deposition flux. Different exposure time of feed spray was undertaken prior to adhesion flux weight determination. Three different sets of inlet temperature (100 oC, 150 OC and 190 oC) and exposure times (of 15 min, 30 min, 60 min, 75 min, 90 min and 115 min) were tested. Samples were evaluated for contact angle, weight of adhesion flux, hygroscopicity and moisture content. There was a sudden increased in deposition flux (p<0.05) as the temperature increased. At 150 and 190°C, the weight of deposition flux was not significant (p>0.05) for both plate materials. The borosilicate plates (BP) registered up to 80% deposit removal whilst Teflon plate (TP) recorded only 20%. Physical observation of the Teflon plates showed that some areas of the plate (100 °C) were fully clear from any particles. Nevertheless, for the borosilicate glass plates, the primary adhered particles tend to retain and smeared along the plates. In addition, there was a substantially negative relationship between the contact angle and adhesion weight, (r = -0,924, p<0.01). The negative connection suggests that by increasing the contact angle, the adhesion weight will decrease and vice versa. The contact angle of the Teflon (PTEFE) surface was approximately 117.2 ± 1.4°, which provided an excellent hydrophobic surface. In this research, the powder with the lowest amount of hygroscopicity was gained at 190 oC using the Teflon plate. For that reason, surface modification was indeed amplified the surface hydrophobicity thus decreasing the deposition flux.

KEYWORDS: Adhesion; Deposition flux; Spray drying; Stickiness; Teflon; Yield

Download this article as:| Copy the following to cite this article: Abidin N. Z, Zubairi S. I, Hashim H. Surface Modification to Reduce Deposition Flux of Spray Dried Noni (Morinda Citrofolia L.) Juice. Biosci Biotech Res Asia 2019;16(4). |

| Copy the following to cite this URL: Abidin N. Z, Zubairi S. I, Hashim H. Surface Modification to Reduce Deposition Flux of Spray Dried Noni (Morinda Citrofolia L.) Juice. Biosci Biotech Res Asia 2019;16(4). Available from: https://bit.ly/34xp6vj |

Introduction

Morinda citrifolia is described as a small or medium sized tree that usually grows in tropical lands. It is commonly known as Noni or Indian mulberry which has been used as both food and medicine [1]. Extract of M. citrifolia has been used for generations in traditional therapy [2]. Noni has been presented in the popular press as a supplementary treatment for various medical conditions, including cancer [3]. Morinda citrifolia L. (Noni) is from the Rubiaceae family, and it is a supply of natural molecules that has been used as a healing plant by the Polynesians for more than 2,000 years [4]. However, many people avoid consuming the juice because of its unpleasant odor. Deodorization process will reduce the undesirable odor of Noni juice which was contributed by medium chain fatty acids such as decanoic acid, hexanoic acid and octanoic acid [2]. Studies done by Haslaniza et al. 2015 has shown that deodorization of Noni extract has been successfully achieved using ion exchange resin with promising results [5].

Spray drying is a method which depends on the properties of wall structures, nature of material to be retained and location. Indirectly, the combination will influence the parameters measured including moisture content, particle size, and density [6]. Spray drying is a technique to produce a dry powder from a liquid by rapidly spraying the feed into a hot drying medium [7]. Powder recovery in spray drying method is a big challenge in food technology. This is primarily because of the nature of food which contains low molecular weight sugars and organic acids, which have a low glass transition temperature [8].

Spray drying of sugars and high acid food materials is associated with stickiness problem. In order to obtain successful drying, numerous methods have been studied such as use of high molecular weight aids to increase glass transition temperature of feed mixture, use of low humidity and low temperature conditions, scrapping of dryer surfaces, cooling of dryer wall by using dehumidified air and surface modification by proteins to encapsulate sugar [9]. The growth of wall depositions in the spray dryer decreases the production of the products and hence raises the costs of manufacturing and maintenance. Powder properties namely, moisture content, bulk density, particle size, hygroscopicity and morphology were influenced by inlet temperature. It was discovered that at a continuous feed flow level, raised the inlet air temperature decreased the residual moisture content. The same activity was found in the different fruit juice powders such as tomato juice, acai juice and pineapple juice [10]. This research is attempted to increase the efficiency of spray dryer by increasing its product recovery (Noni powder) through physico-chemical treatment on the surface of drying chamber of spray dryer by using different inlet temperature.

Table 1: Experimental design with coded and real values, moisture content (M) and hygroscopicity (H) of spray-dried Noni powders using Teflon plate. Different superscripts letters in the same column mean significantly differences (p<0.05)

| Test | Inlet Temperature (oC) | Moisture Content (%) | Hygroscopicity |

| 1 | 100 | 5.07 ± 0.1g | 15.5 ± 0.3b |

| 2 | 100 | 3.75 ± 0.2ef | 13.9 ± 0.1a |

| 3 | 100 | 4.67 ± 0.2g | 13.2 ± 0.0a |

| 4 | 150 | 3.34 ± 0.1cd | 17.3 ± 0.4d |

| 5 | 150 | 3.56 ± 0.1de | 17.6 ± 0.2c |

| 6 | 150 | 4.07 ± 0.2f | 16.5 ± 0.1c |

| 7 | 190 | 2.66 ± 0.1a | 18.9 ± 0.2e |

| 8 | 190 | 2.8 ± 0.1ab | 18.5 ± 0.3de |

| 9 | 190 | 3.1 ± 0.1bc | 17.6 ± 0.2c |

Materials and Methods

Fruit Juice Extraction

The Noni fruit were obtained from a consistent local sources at UKM-MTDC Technology Centre, Bangi, Selangor. The fruits were allowed to ripen to a soft consistency for 3 days. The Noni juice was prepared by selecting the fruits of stage 4 maturity index as shown in the Figure 1 [11]. The fruits were then being cut into smaller size and were added with distilled water in ratio of 1:1 (w/w) and blended using a food blender (7011S, Waring Blender, Torrington, USA). After that, the juice was filtered with muslin cloth and centrifuged at 8000 rpm for 15 minutes (Sorvall HS 23, Thermo Electron Corporation, USA). Centrifugation helps in removing the fruit pulp from the extract.

|

Figure 1: Freshly harvested Noni fruits at stage 4 maturity |

Conditioning of resin

Approximately of 0.5 g Amberlite IRA-67 resin was soaked in 5.0 ml HCl (5%) for 45 minutes [12, 13]. Later, the resin was filtered with filter paper (Sartorius 1288) then re-soaked in 15 ml deionized water for 2 hours. To ensure the removing of residue, the resin was washed again with deionized water. Finally, the resin was filtered and was dried in dessicator for 24 hours

Deacidification of Noni Juice using Ion Exchange Resin

Noni juice extract was mixed with 0.5% (w/v) Amberlite IRA-67 resin; 0.1 g resin = 0.02 L sample in conical flask and was agitate in orbital shaker (WiseCube, Daihan Scientific, Korea) at 120 rpm for 327 minutes [14,15,16]. The sample was then filtered with filter paper (Sartorius 1288) and kept in -20 °C in Scott bottle before being used for further studies.

Spray Dryer Operating Conditions

The sample was fed into a lab-plant spray-dryer B-290 (Buchi Mini Spray Dryer, Flawil, Switzerland) by using a peristaltic pump. A cyclone air separator/powder recovery system was utilized. The dryer was designed as such that the outlet and inlet air temperature are the result of a combination of the inlet temperature, the aspirator setting, the pump setting and feed concentration [7]. After spray drying process, the powders deposited were collected and then weighed. The dried powders were collected from the cyclone separator and stored in desiccators at room temperature until further analysis.

Preparation of hydrophobic film

Microscope slides (Borosilicate, 76 mm x 26 mm x 1 mm) were obtained from Quasi-S Technology (M) Sdn. Bhd. and were used to mimic the chamber wall of a spray dryer (BUCHI Mini Spray Dryer B-290). To measure of any particles agglomeration occurs at the walls of the spray dryer (rather than in the bulk of the dryer), the sample plates were left in the spray dryer for 1 hour to allow of any noni powder sticks to treated surfaces. Two sets of plates were involved in the preparation of the hydrophobic film; borosilicate glass plates (BP) and Teflon plates (TP). The TP were fabricated by covering the borosilicate glass involved in the experiment by using Polytetrafluoroethylene preparation (60 wt % dispersion in H2O). Films were fabricated by dip-coating the PTFE emulsion onto glass slides, which were then placed in an oven at 100 °C for 20 minutes to remove any residual water [17].

Contact Angle (CA) Measurement

The water contact angle (WCA) was measured using an Automated Contact Angle Goniometer (Model 100) from Rame-Hart Inc. with MB-Ruler Software. The contact angle measurement was done using a static contact angle technique (Drop Tensile Analyzer). An amount of 0.5 ml deionized water was dropped at three separate points on the glass surface of the treated and untreated slides [18, 19]. All measurements were carried out in triplicates (n = 3).

Determination of Flux Adhesion Weight

Flux adhesion weight was determined using an analytical balance SHIMADZU (model: ATX224) by assessing the weight of the plates before and after the feed spray [19]. The deposition flux was obtained at three different temperatures. The feed spray was carried out 30 min prior to deposition flux determination. For each set of plates, three inlet temperatures (120, 150 and 170 0C) were analyzed [20]. In selecting these two plate materials, only the surface energy properties were taken into account. The plates were put on the stage in the drying chamber randomly as shown in Figure 2 and the weight of deposition flux on the plates were determined (n = 3).

|

Figure 2: The Borosilicate and Teflon plates were placed horizontally in the bottom of drying chamber. The adhesion flux deposited at plates were observed and weighed (n = 3) |

Hygroscopicity (H)

Hygroscopicity of the powders was decided based on the method illustrated by Cai and Corke (2000), with some modification. About 0.5 g of each powder were put in a desiccator containing a saturated solution of NaCl (RH 75.3%). The results were performed as the mass of water absorbed per 100 g of sample after seven days [21] in triplicates (n = 3).

Moisture Content (M)

The moisture content of the spray dried samples was determined by using a moisture analyzer. Samples with predetermined masses were placed in an oven (Memmert) at 70 °C until consecutive weighing, which was done at 2 h intervals, provided less than 0.3% variation [9]. The product moisture content was determined from the weight loss by averaging three measurements (n = 3).

Statistical Analysis

The experimental results in the single factor experiments were analyzed using Statistical Package for the Social Science SPSS version 23.0 (SPSS Inc., Chicago, IL, USA). The data was analyzed by analysis of variance

(ANOVA) method. Significance differences between the means were determined by One-Way ANOVA (Tukey’s multiple comparison) and independent t-test (p<0.05).

Results and Discussion

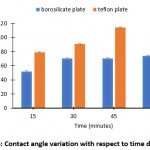

Result of Duration Treatment on Contact Angle

In the present research, the duration of treatment involved was between 15-60 minutes. Figure 3 shows a substantially significant difference (p<0.05) between the value of the contact angle of the untreated slide (Borosilicate plate) with the slide that was treated (Teflon plate) (p<0.05). This showed that 15 minutes treatment time was not sufficient to raise the contact angle value. An increase in the contact angle value also can be observed in this study on Teflon coated plate with increasing duration time. The value of contact angle on Teflon coated plate (TP) achieved the highest on the 45-minute treatment period, while the Borosilicate plate (untreated) start to maintain its value from 30-minute treatment until 60-minute of treatment. The interfacial surface energy of the equipment and product plays a vital role in controlling the adhesion phenomenon, while the interphase diffusion and viscoelastic behavior control the cohesive phenomenon. In this study, the contact angle value indicated that the BP had a more hydrophilic character as compared with TP. The contact angle of TP (117o) was relatively high, showing its poor hydrophilicity significantly (p<0.05) compared to BP.

|

Figure 3: Contact angle variation with respect to the time duration |

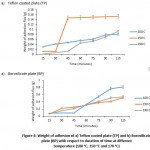

Effect of Weight Adhesion Flux and Duration of Treatment

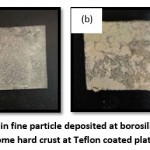

According to this result in this study, there is an increment (p<0.05) in weight of adhesion flux on Teflon coated plate and borosilicate plate. A rise in the inlet air temperature from 100 oC to 190 oC resulted in a significant rise (p<0.05) in the particle size distribution of the powder. By increasing the inlet air temperature, particles changed into a larger size because of the greater swelling of particles [10]. General trend for the plate at different inlet temperature clearly indicated that usage of Teflon coated plate (TP) resulted with less deposit when compared to Borosilicate plate (BP) show higher value of weight adhesion flux at 190 oC (p<0.05) as compared to Teflon coated plate. At 150 oC and 100 oC of inlet temperature, it seems to be insignificant value between Teflon and Borosilicate plate. Drying at higher temperatures resulted in faster drying rates, which led to the early formation of a structure and that did not allow the particles to shrink during drying [21]. When the inlet air temperature is low, the particle remains more shrunk and smaller. However, at 100 oC, both plates have low weight of adhesion compare to 150 oC and 190 oC. Figure 5 show the fine particle deposited at Teflon coated plate, meanwhile the Borosilicate plate observed the deposition of hard crust. This is linked with the different drying rates, which has the highest rate at higher temperatures, resulting in the faster water evaporation and then it led to the formation of smooth and hard crust [10]. However, particles at 120 oC and 150 oC showed a rigid with wrinkled structures due to the lower operating temperature [8]. From this observation, if the inlet temperature is low, the heat does not have enough time to dry the noni juice and thus the high moisture content in the powdery product affect its stickiness at the drying chamber wall and eventually decrease the product yield. Furthermore, when the drying time too long, an accumulation of underdried large particles on the chamber wall may occur, which leads to low yield values end product. In average, at 150 oC and 170 oC, the deposition fluxes were obviously lower for TP.

|

Figure 4: Weight of adhesion of a) Teflon coated plate (TP) and b) Borosilicate plate (BP) with respect to duration of time at different temperature (100 oC, 150 oC and 170 oC) |

|

Figure 5: The flux in fine particle deposited at borosilicate plate (a) and become hard crust at Teflon coated plate (b) |

Effect of Hygroscopicity and Moisture Content

Hygroscopicity refers to the ability of a material to soak up moisture from the surrounding, and it is an important property to be taken into account in food stability. Low moisture inhibits the agglomeration of particles preventing the caking of powders, which could lessen retention of active properties and other properties such as flow and dispersion of powders [22]. With a rise in the inlet air temperature, powders with lower moisture content were obtained. On the contrary, rising the air flow rate usually causes powders to have higher moisture content on the both plates (p<0.05). This might be due to the shorter staying of particles/droplets in the chamber and smaller values of vapor pressure of water [6]. From this research, the addition of Teflon coated on the plates leads to a significant decrease (p<0.05) of the hygroscopicity compared to Borosilicate plates (non-coating) at 100 oC. This demonstrated the ability of Teflon to improve the hygroscopicity values of Noni fruit extract powders. Moreover, temperature of inlet also affected the hygroscopicity values of powders obtained using Teflon coating. Temperature at 100 oC was the variable that most affected (p<0.05) compare to 150 oC and 190 oC. It is important to note that for samples with low moisture contents the hygroscopicity values were higher. This can be justified because higher temperatures may produce smaller particles, expanding the exposure area of the particles to the medium [22].

Table 2 Experimental design with coded and real values, moisture content (M) and hygroscopicity (H) of spray-dried Noni powders using Borosilicate plate. Different superscripts letters in the same column mean significantly differences (p<0.05)

| Test | Inlet Temperature (oC) | Moisture Content (%) | Hygroscopicity |

| 1 | 100 | 3.07 ± 0.1cde | 17.5 ± 0.3d |

| 2 | 100 | 3.15 ± 0.3de | 15.9 ± 0.2bc |

| 3 | 100 | 3.67 ± 0.2f | 13.7 ± 0.0a |

| 4 | 150 | 2.54 ± 0.2bc | 17.3 ± 0.4e |

| 5 | 150 | 3.42 ± 0.2cd | 15.6 ± 0.2c |

| 6 | 150 | 1.87 ± 0.3ef | 14.5 ± 0.1b |

| 7 | 190 | 2.37 ± 0.1a | 19.9 ± 0.2f |

| 8 | 190 | 2.63 ± 0.1ab | 17.5 ± 0.3d |

| 9 | 190 | 8.4± 0.1bc | 33.6 ± 0.5b |

Conclusion

The present study established a simplified model of spray drying based on fundamental parameter concentrating on application in food industry. The development of this model allows the estimation of some parameters for the design of processes preventing stickiness with lead to waste with successive laboratory tests throughout the development of new alternative by spray drying. These findings in this study showed that the parameters studied, inlet temperature and duration of treatment (minute) showed significant effects (p<0.05) on the contact angle (o) and weight of adhesion (g). Compared to untreated surface (BP), the contact angle rose and the weight of the adhesion decreased significantly (p<0.05). This study revealed there was a rise in the contact angle on TP, and the value of the contact angle is considered as hydrophobic (117.2 ± 1.4°). The borosilicate plates registered up to 80% deposit removal while Teflon plate recorded only 20%. Physical observation on the Teflon plates revealed that some regions on the plate (190 °C) were totally clear from any particles. However, for the borosilicate glass plates, the primary adhered particles tend to retain and smeared along the plates. The powder with the lowest hygroscopicity was obtained at 190oC using Teflon coated plate. Further work can be done using different plasma system which were easier to manage such as atmospheric pressure plasma system that do not need the use of vacuum chamber.

Conflict of Interest

Any of authors have no conflict of interest to declare

Acknowledgments

I would like to thank the Ministry of Higher Education (MOHE), Malaysia for providing financial support to this research project (GUP-2018-080).

References

- West, B. J., Deng, S., & Jensen, C. J. (2019). Morinda citrifolia (Noni) Fruit Juice Inhibits Endocannabinoid Degradation Enzymes. Journal of Biosciences and Medicines, 7(07), 22.

- Nur Hafiza, Z., Maskat, M. Y., Liew, S. L., & Mamot, S. (2013). Fermentation of Morinda citrifolia extract by Saccharomyces cerevisiae as affected by substrate concentration, inoculum size, temperature and fermentation time. International Food Research Journal, 20(4), 1889-189.

- Amy, B. 2012. Anticancer activity of Morinda citrifolia (Noni) fruit: A review. Phytotherapy Research 26(10), 1427-1440.

- Coutinho de Sousa, B., Reis Machado, J., da Silva, M. V., da Costa, T. A., Lazo-Chica, J. E., Degasperi, T. D. P. & Freire Oliveira, C. J. (2017). Morinda citrifolia (noni) fruit juice reduces inflammatory cytokines expression and contributes to the maintenance of intestinal mucosal integrity in DSS experimental colitis. Mediators of inflammation, 2017.

- Haslaniza, H., Wan Yaacob, W.A., Osman, H. and Maskat, M. Y. 2015. Interaction of antioxidants and organic acid from noni (Morinda citrifolia L.) juice with ion exchange resins during deodorization via deacidification. Der Pharma Chemica 7(9), 9-21.

- Kalantari, M., Niakousari, M., Haghighi‐Manesh, S., & Rasouli, M. (2018). Fig extract drying: The relationship between the main operating parameters of a pilot‐scale spray dryer and product specifications. Food science & nutrition, 6(2), 325-333

- Kiritsakis, K., Goula, A. M., Adamopoulos, K. G., & Gerasopoulos, D. (2018). Valorization of olive leaves: spray drying of olive leaf extract. Waste and biomass valorization, 9(4), 619-633.

- Woo, M., Daud, W. R. W., Tasirin, S. M., & Talib, M. Z. M. (2009). Controlling food powder deposition in spray dryers: wall surface energy manipulation as an alternative. Journal of Food Engineering, 94(2), 192-198

- Chasekioglou, A. N., Goula, A. M., Adamopoulos, K. G., & Lazarides, H. N. (2017). An approach to turn olive mill wastewater into a valuable food by-product based on spray drying in dehumidified air using drying aids. Powder technology, 311, 376-389.

- Phisut, N. (2012). Spray drying technique of fruit juice powder: some factors influencing the properties of product.

- Yien, Y.S., Hassan, O. & Zubairi, S.I (2016). Deodorizing Mechanism of β-Cyclodextrin-Organic Acids Inclusion against Strong Odor of Morinda Citrifolia (Mengkudu) Juice. Jurnal Teknologi (Sciences and Engineering). 79:10; p67-75

- Abidin, N.Z., Janam, A. & Zubairi, S.I. (2016). Adsorption of Saponin Compound in Carica papaya Leaves Extract Using Weakly Basic Ion Exchanger Resin. In AIP Conference Proceedings (Vol. 1784, 030039). AIP Publishing.

- Hashim, H., Ahmad, W. Y. W., Zubairi, S. I. & Maskat, M. Y. (2019). Effect of pH on Adsorption of Organic Acids and Phenolic Compounds by Weakly Basic Ion Exchanger. Jurnal Teknologi (Sciences and Engineering). 81:1; p69-81.

- Amran, S. N. S., Abidin, A. Z. & Zubairi, S. I. (2018). Saponin Bitterness Reduction of Carica Papaya Leaves Extract through Weakly Basic Ion Exchange Resins Adsorption. Journal of Food Quality Volume 2018, Article ID 5602729, 11 pages

- Hashim, H., Zubairi, S. I., Mustapha, W. A. M. & Maskat, M. Y. (2018). Characterizing the Deacidification Adsorption Model of Organic Acids and Phenolic Compounds of Noni Extract using Weak Base Ion Exchanger. Journal of Chemistry Volume 2018, Article ID 637692

- Hashim, H., Ahmad, W. Y. W., Zubairi, S. I. & Maskat, M. Y. (2015). Potential of Amberlite IRA 67 Resin For Deacidification of Organic Acids In Noni Juice. Der Pharma Chemica. 7:12 (2015) 62-69.

- Zhang, Y.-Y., Ge, Q., Yang, L.-L., Shi, X.-J., Li, J.-J., Yang, D.-Q., & Sacher, E. (2015). Durable superhydrophobic PTFE films through the introduction of micro-and nanostructured pores. Applied Surface Science, 339, 151-157

- Ramlan, N., Zamri, N. W. M., Maskat, M. Y., Hoong, C. O., Theng, L. Y., & Zubairi, S. I. (2018a). Effect of plasma treatment (He/CH4) on glass surface for the reduction of powder flux adhesion in the spray drying process. In AIP Conference Proceedings (Vol. 1940, No. 1, p. 020093). AIP Publishing

- Ramlan, N., Zamri, N. W. N., Maskat, M. Y., Aizad, S. & Zubairi, S. I. (2018b). Effect of Plasma Treatment (He/CH4) on the Glass Surface during Drying to Reduce Powder Flux Adhesion. Sains Malaysiana, Volume 47 No. 6: 1147-1155.

- Woo, M. W., Daud, W. R. W., Tasirin, S. M., & Talib, M. Z. M. (2007). Optimization of the spray drying operating parameters – A quick trial-and-error method. Drying Technology, 25(10), 1741-1747

- Reineccius, G. A. (2001). The spray drying of food ingredients. In The Encapsulation of Food Ingredients(pp. 151-184). Leatherhead Publ.

- Daza, L. D., Fujita, A., Fávaro-Trindade, C. S., Rodrigues-Ract, J. N., Granato, D., & Genovese, M. I. (2016). Effect of spray drying conditions on the physical properties of Cagaita (Eugenia dysenterica DC.) fruit extracts.Food and bioproducts processing, 97, 20-29.

This work is licensed under a Creative Commons Attribution 4.0 International License.